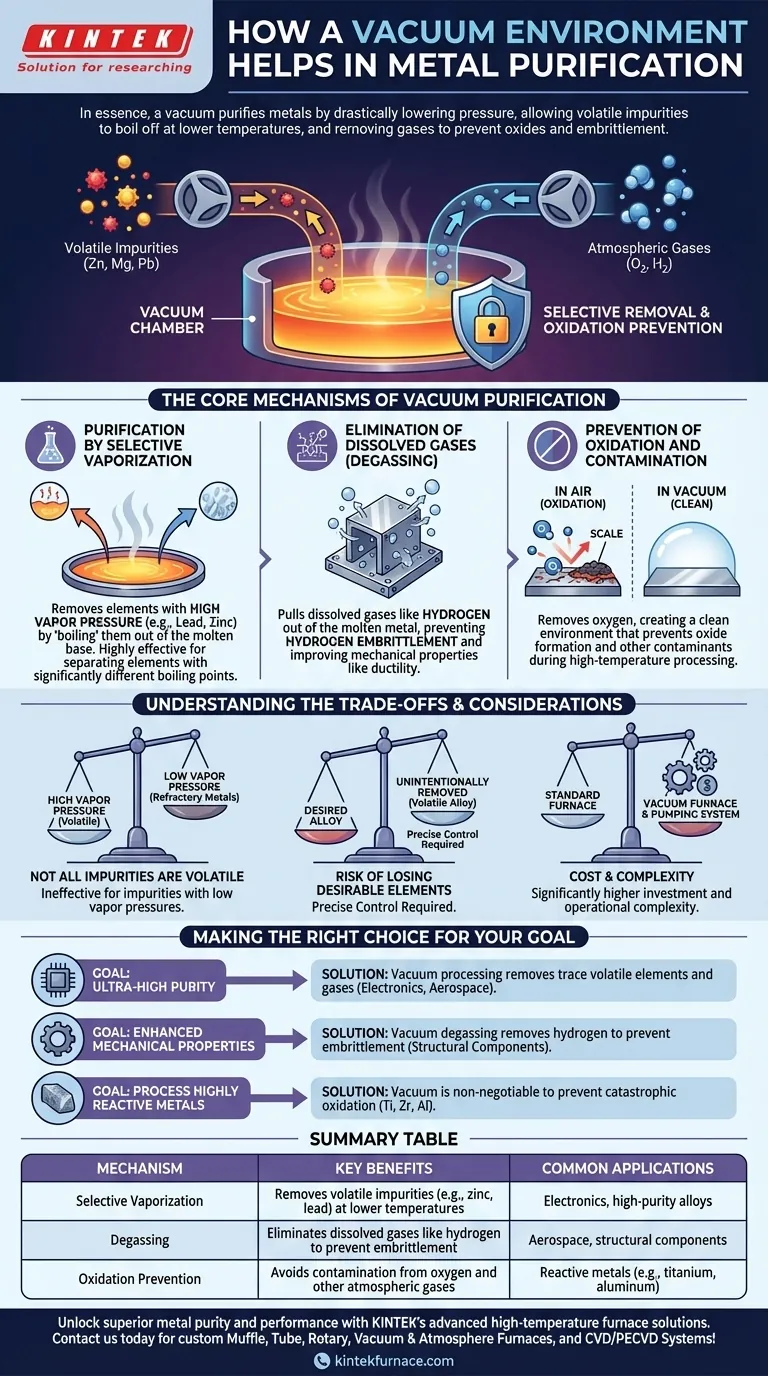

In essence, a vacuum environment purifies metals in two primary ways. First, by drastically lowering the pressure, it allows volatile impurities like zinc, magnesium, and lead to boil off and be removed from the molten metal at temperatures far below their normal boiling points. Second, it removes atmospheric gases like oxygen and hydrogen, preventing the formation of undesirable oxides and eliminating dissolved gases that can degrade the metal's structural integrity.

By removing atmospheric pressure and reactive gases, a vacuum creates an environment where unwanted elements can be selectively removed and harmful chemical reactions are prevented, unlocking a level of purity and material quality that is unattainable in open air.

The Core Mechanisms of Vacuum Purification

To understand the value of vacuum processing, we must look at how it fundamentally changes the behavior of materials at high temperatures. It isn't an additive process; it's a subtractive one that removes the barriers to achieving high purity.

Purification by Selective Vaporization

Every element has a vapor pressure, which is its tendency to evaporate at a given temperature. In a normal atmosphere, this evaporation is suppressed by the surrounding air pressure.

By creating a vacuum, we remove that external pressure. This allows elements with a high vapor pressure—often impurities like lead, zinc, and magnesium—to effectively "boil" out of the molten base metal and be pumped away.

This process is highly effective for separating elements with significantly different boiling points, achieving a level of refinement that would otherwise be impossible.

Elimination of Dissolved Gases (Degassing)

Metals, especially when molten, can absorb ambient gases. The most damaging of these is often hydrogen, which can become trapped in the metal's crystal structure as it cools.

This leads to a dangerous condition known as hydrogen embrittlement, which severely reduces the metal's ductility, toughness, and fatigue strength, making it brittle and prone to sudden failure.

Vacuum heat treatment pulls these dissolved gases out of the metal, a process called degassing. This significantly enhances the final mechanical properties and reliability of the component.

Prevention of Oxidation and Contamination

Heating most metals in the presence of oxygen causes rapid oxidation, forming a layer of scale or impurities on the surface and within the material. This is a major source of contamination.

A vacuum furnace removes virtually all the oxygen from the processing chamber. This creates a clean, controlled environment that prevents oxidation, even at the extreme temperatures required for melting and sintering.

Furthermore, this clean environment prevents other atmospheric contaminants from being introduced into the metal during its most vulnerable, high-temperature state.

Understanding the Trade-offs and Considerations

While powerful, vacuum purification is not a universal solution. Its application requires a clear understanding of its limitations and the associated trade-offs.

Not All Impurities Are Volatile

Vacuum purification is most effective for impurities that are significantly more volatile (have a higher vapor pressure) than the base metal.

It is not an effective method for removing impurities with low vapor pressures, such as refractory metals, which will remain in the melt. The selection of a purification method must match the specific impurities you need to remove.

The Risk of Losing Desirable Elements

The process is non-selective when it comes to volatility. If a desired alloying element also has a high vapor pressure, it can be unintentionally removed along with the unwanted impurities.

Controlling this requires precise management of temperature and pressure levels to create a processing window where impurities are removed while valuable alloys are retained.

The Cost and Complexity of Equipment

Vacuum furnaces and their associated pumping systems are significantly more complex and expensive to acquire, operate, and maintain than standard atmospheric furnaces.

This higher cost means the process is typically reserved for applications where the benefits of high purity or enhanced mechanical properties justify the investment.

Making the Right Choice for Your Goal

The decision to use vacuum purification should be driven by the specific outcome you need to achieve for your material.

- If your primary focus is achieving ultra-high purity: Vacuum processing is essential for removing trace volatile elements and gases required for sensitive applications like electronics or aerospace alloys.

- If your primary focus is enhancing mechanical properties: Vacuum degassing is the most effective way to remove hydrogen and prevent embrittlement, directly improving the toughness and fatigue life of structural components.

- If your primary focus is processing highly reactive metals: A vacuum environment is non-negotiable for materials like titanium, zirconium, and aluminum, as it's the only way to prevent catastrophic oxidation during heat treatment.

Ultimately, vacuum purification provides the control needed to achieve a metal's true performance potential.

Summary Table:

| Mechanism | Key Benefits | Common Applications |

|---|---|---|

| Selective Vaporization | Removes volatile impurities (e.g., zinc, lead) at lower temperatures | Electronics, high-purity alloys |

| Degassing | Eliminates dissolved gases like hydrogen to prevent embrittlement | Aerospace, structural components |

| Oxidation Prevention | Avoids contamination from oxygen and other atmospheric gases | Reactive metals (e.g., titanium, aluminum) |

Unlock superior metal purity and performance with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control