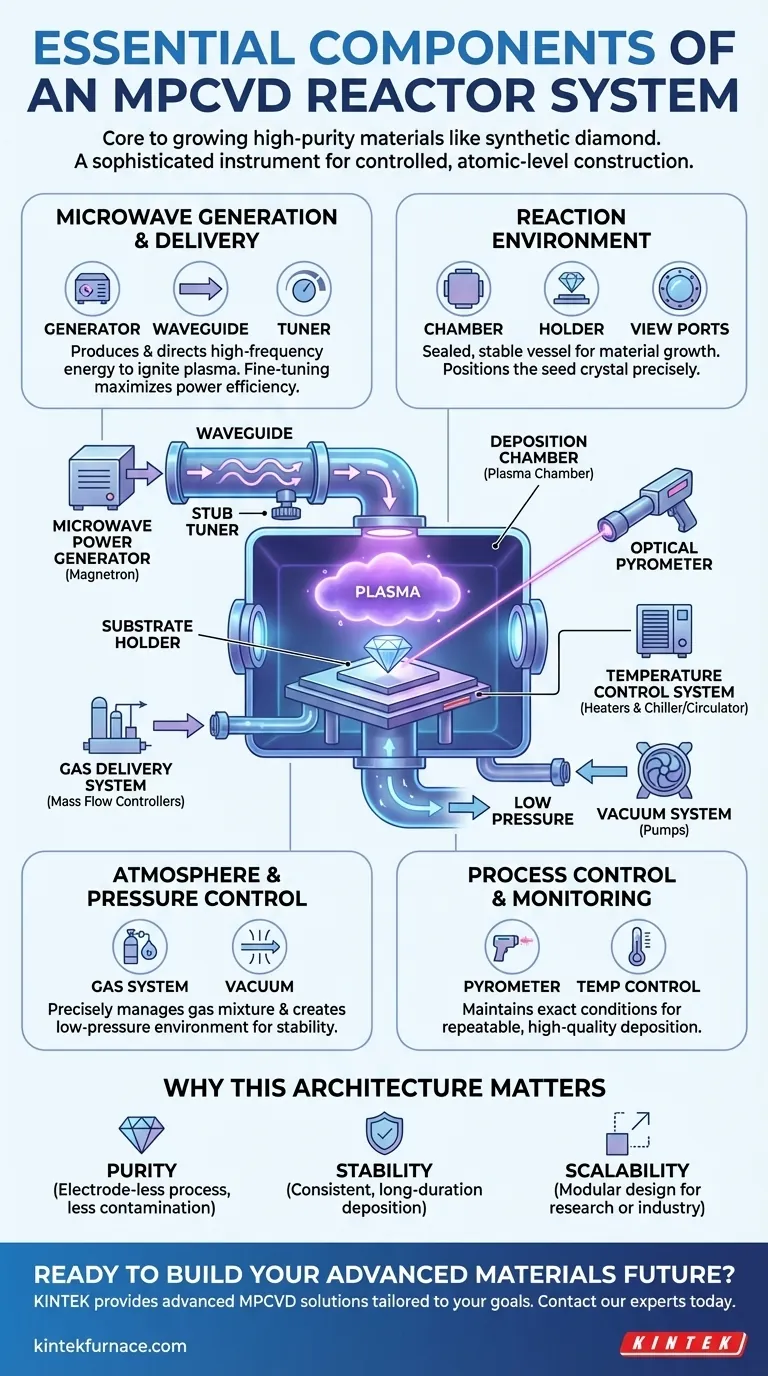

At its core, an MPCVD reactor is a highly controlled system designed to grow high-purity materials, most notably synthetic diamond. The essential components include a microwave power generator, a waveguide to direct that power, a deposition chamber to contain the reaction, a substrate stage to hold the material, a gas delivery system for reactants, a vacuum system to control pressure, and a temperature control system to ensure precision.

An MPCVD system is not merely a collection of parts, but a sophisticated instrument where each component works in concert. The ultimate goal is to create and sustain a stable, high-energy plasma in a pristine, low-pressure environment, enabling the atomic-level construction of advanced materials.

The Core Components: A Functional Breakdown

To understand how an MPCVD reactor functions, it is best to group its components by their role in the deposition process: energy generation, reaction environment, atmosphere control, and process monitoring.

Microwave Generation and Delivery

The process begins with the creation of microwave energy, which is used to ignite and sustain the plasma.

A microwave power generator, often a magnetron, is the heart of the system, producing high-frequency microwave energy (typically 2.45 GHz).

This energy travels through a waveguide, which is essentially a metal pipe that directs the microwaves toward the reaction chamber.

A stub tuner is often included in the waveguide path. This component allows for fine-tuning to maximize the power delivered to the plasma and minimize reflected power, ensuring energy efficiency.

The Reaction Environment

The reaction environment is where the material growth actually occurs. It must be a sealed, stable, and clean space.

The deposition chamber (or plasma chamber) is a vacuum-sealed vessel, usually made of stainless steel, that houses the entire reaction. It often includes view ports for observation.

Inside the chamber, a substrate holder or stage positions the material (the "seed" crystal) where the new film will be grown.

Atmosphere and Pressure Control

The specific gas mixture and pressure inside the chamber are critical variables that determine the quality of the final material.

A gas delivery system uses mass flow controllers to precisely mix and inject reactant gases (like methane and hydrogen for diamond growth) into the chamber.

A vacuum system, consisting of pumps, creates the necessary low-pressure environment. Maintaining a vacuum is crucial for plasma stability and preventing contamination from atmospheric gases.

Process Control and Monitoring

Repeatability and quality depend on maintaining exact conditions throughout the often lengthy deposition process.

The substrate temperature measurement assembly is vital for process control. An optical pyrometer is commonly used to measure the high temperatures of the substrate without physical contact.

A temperature control system, which includes both heaters in the substrate stage and an external water circulator (or chiller), actively manages the temperature to prevent it from becoming too high or too low. This precise regulation is one of the most critical factors for material quality.

Why This Architecture Matters

The specific design of an MPCVD system is not arbitrary; it is engineered to overcome the limitations of other deposition methods and deliver key advantages.

Purity and Efficiency

Because the plasma is generated by microwaves, there are no internal electrodes inside the chamber. This electrode-less process is a defining feature of MPCVD, as it significantly reduces the risk of contamination from eroded electrode material, leading to higher-purity films.

Stability and Reproducibility

The combination of precise power, gas, and temperature controls allows for remarkably stable plasma conditions. This enables continuous deposition for extended periods—sometimes hundreds of hours—without degrading the quality of the material being grown, ensuring excellent run-to-run reproducibility.

Scalability for Industrial Use

The modular design of MPCVD systems makes them highly adaptable. The power source, chamber size, and gas delivery can be scaled up to accommodate larger substrates or higher throughput, making the technology suitable for both laboratory research and industrial-scale production.

Applying This to Your Goal

Understanding these components allows you to focus on the subsystems most critical to your specific objective.

- If your primary focus is high material purity: Your attention should be on the vacuum system's integrity and the purity of the gases delivered by the gas flow system.

- If your primary focus is process repeatability: Concentrate on the stability of the microwave power generator and the precision of the temperature control and measurement systems.

- If your primary focus is scaling up production: The key variables are the power capacity of the microwave generator and the physical size and design of the deposition chamber and substrate stage.

Ultimately, mastering MPCVD technology comes from understanding the dynamic interplay between these essential components to create a perfectly controlled environment.

Summary Table:

| Component Category | Key Parts | Primary Function |

|---|---|---|

| Energy Generation | Microwave Generator, Waveguide, Stub Tuner | Create and direct microwave energy to ignite plasma. |

| Reaction Environment | Deposition Chamber, Substrate Holder | Provide a sealed, stable space for material growth. |

| Atmosphere Control | Gas Delivery System, Vacuum System | Precisely manage gas mixture and pressure. |

| Process Monitoring | Temperature Control, Optical Pyrometer | Ensure stable, repeatable deposition conditions. |

Ready to Build Your Advanced Materials Future?

Understanding the components is the first step; integrating them into a high-performance, reliable system is the next. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced MPCVD solutions tailored to your unique research or production goals.

Whether you are focused on achieving ultimate material purity, ensuring process repeatability, or scaling up for industrial production, our deep customization capabilities ensure your reactor system is precisely engineered for success.

Let's discuss your specific application requirements. Contact our experts today to explore how KINTEK's MPCVD technology can power your innovations.

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production