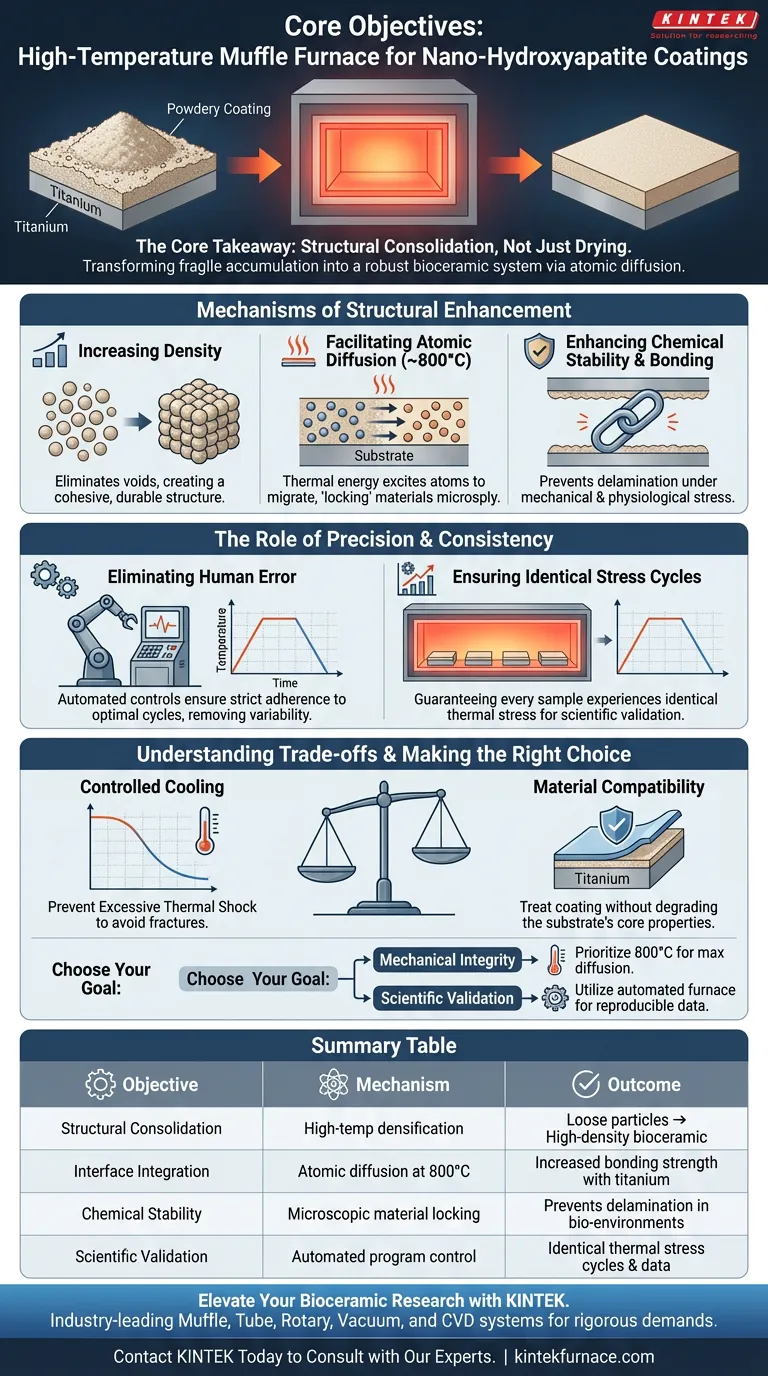

The fundamental purpose of using a high-temperature muffle furnace for nano-hydroxyapatite coatings is to drive the transition from a loose assembly of particles into a unified, high-density bioceramic layer. Through exposure to temperatures around 800°C, the process triggers atomic diffusion at the interface of the coating and the titanium alloy substrate. This significantly elevates the system's mechanical bonding strength and overall chemical stability.

Core Takeaway: Thermal treatment is a structural consolidation process, not merely a drying phase. By inducing atomic diffusion, the furnace integrates the ceramic coating with the metal substrate, transforming it from a fragile physical accumulation into a mechanically robust system capable of withstanding biological stress.

Mechanisms of Structural Enhancement

The primary reference dictates that the core value of this treatment lies in changing the physical state of the coating.

Increasing Coating Density

Before thermal treatment, nano-hydroxyapatite coatings often exist as a loose physical accumulation of particles.

The high-temperature environment consolidates these particles. This densification eliminates voids and creates a cohesive, integrated structure that is far more durable than the untreated material.

Facilitating Atomic Diffusion

The critical mechanism at work at temperatures such as 800°C is atomic diffusion.

The thermal energy excites atoms within both the coating and the titanium alloy substrate. This causes them to migrate across the boundary layer, effectively "locking" the two materials together at a microscopic level.

Enhancing Chemical Stability and Bonding

The result of diffusion and densification is a dramatic improvement in bonding strength.

A coating that has undergone this thermal cycle is chemically stable and mechanically integrated. This prevents the coating from delaminating or detaching when subjected to mechanical loads or physiological environments.

The Role of Precision and Consistency

While the primary goal is structural integration, supplementary data suggests that how the heat is applied is just as critical as the heat itself.

Eliminating Human Error

Advanced muffle furnaces utilize automated program controls to manage the thermal cycle.

This automation removes operator variability. It ensures that the specific time-temperature curves required for optimal diffusion are followed strictly, without deviation.

Ensuring Identical Stress Cycles

Scientific validation requires that all test samples undergo the exact same conditions.

By controlling the cycle—for example, holding a constant high temperature for 55 minutes followed by 5 minutes of rapid cooling—the furnace ensures every sample experiences identical thermal stress. This allows researchers to scientifically compare how different variables affect the failure life of the coatings.

Understanding the Trade-offs

High-temperature treatment is powerful, but it requires careful management of thermal physics.

The Necessity of Controlled Cooling

The process often involves specific cooling rates, such as the rapid cooling mentioned in the supplementary data.

If this cooling phase is not precisely controlled, it can introduce excessive thermal shock. While some stress is necessary to test spallation limits, uncontrolled cooling could fracture the coating before it is ever put to use.

Material Compatibility

The temperature must be high enough to cause diffusion (800°C) but must be monitored to ensure it does not degrade the substrate.

The objective is to treat the coating, not to fundamentally alter the core properties of the titanium alloy substrate beyond the diffusion interface.

Making the Right Choice for Your Goal

When configuring a thermal treatment protocol for nano-hydroxyapatite, your specific objectives should dictate your furnace parameters.

- If your primary focus is Mechanical Integrity: Prioritize temperatures (e.g., 800°C) that maximize atomic diffusion to prevent coating delamination.

- If your primary focus is Scientific Validation: Utilize an automated furnace to strictly adhere to time-temperature curves, ensuring reproducible data for failure life analysis.

Ultimately, the muffle furnace is the tool that bridges the gap between a fragile ceramic powder and a viable, load-bearing biomedical implant.

Summary Table:

| Objective | Mechanism | Outcome |

|---|---|---|

| Structural Consolidation | High-temperature densification | Transforms loose particles into high-density bioceramic layers |

| Interface Integration | Atomic diffusion at 800°C | Increases mechanical bonding strength with titanium substrates |

| Chemical Stability | Microscopic material locking | Prevents delamination in physiological environments |

| Scientific Validation | Automated program control | Ensures identical thermal stress cycles and reproducible data |

Elevate Your Bioceramic Research with KINTEK

Precision is paramount when managing atomic diffusion and thermal stress cycles for advanced medical coatings. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to meet the rigorous demands of laboratory research and manufacturing.

Backed by expert R&D, our furnaces offer the automated control and temperature uniformity required to transform fragile powders into robust biomedical implants. Looking for a customizable high-temperature solution tailored to your unique research needs?

Contact KINTEK Today to Consult with Our Experts

Visual Guide

References

- Klaudia Malisz, Alina Sionkowska. Study of Nanohydroxyapatite Coatings Prepared by the Electrophoretic Deposition Method at Various Voltage and Time Parameters. DOI: 10.3390/ma17102242

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the specific role of a Muffle Furnace in processing solar cell coatings? Unlock Superior Durability and Efficiency

- Why Use a Muffle Furnace for TiO2 Sol-Gel? Achieve Precise Phase Control and Purity

- What personal protective equipment (PPE) is recommended for benchtop furnace use? Ensure Lab Safety with Proper Gear

- How often should a muffle furnace undergo maintenance? Ensure Longevity and Safety with Proactive Care

- What is the primary role of a muffle furnace in DPC/RuPt catalyst calcination? Achieve 800 °C Precision

- How does a Laboratory Chamber Furnace ensure the quality of TiO2-NiO thin films? Optimize Thermal Treatment Precision

- What maintenance checks are required for a muffle furnace? Ensure Safety and Accuracy in Your Lab

- What is the significance of high-temperature furnace equipment in electrode testing? Ensure Industrial Peak Performance