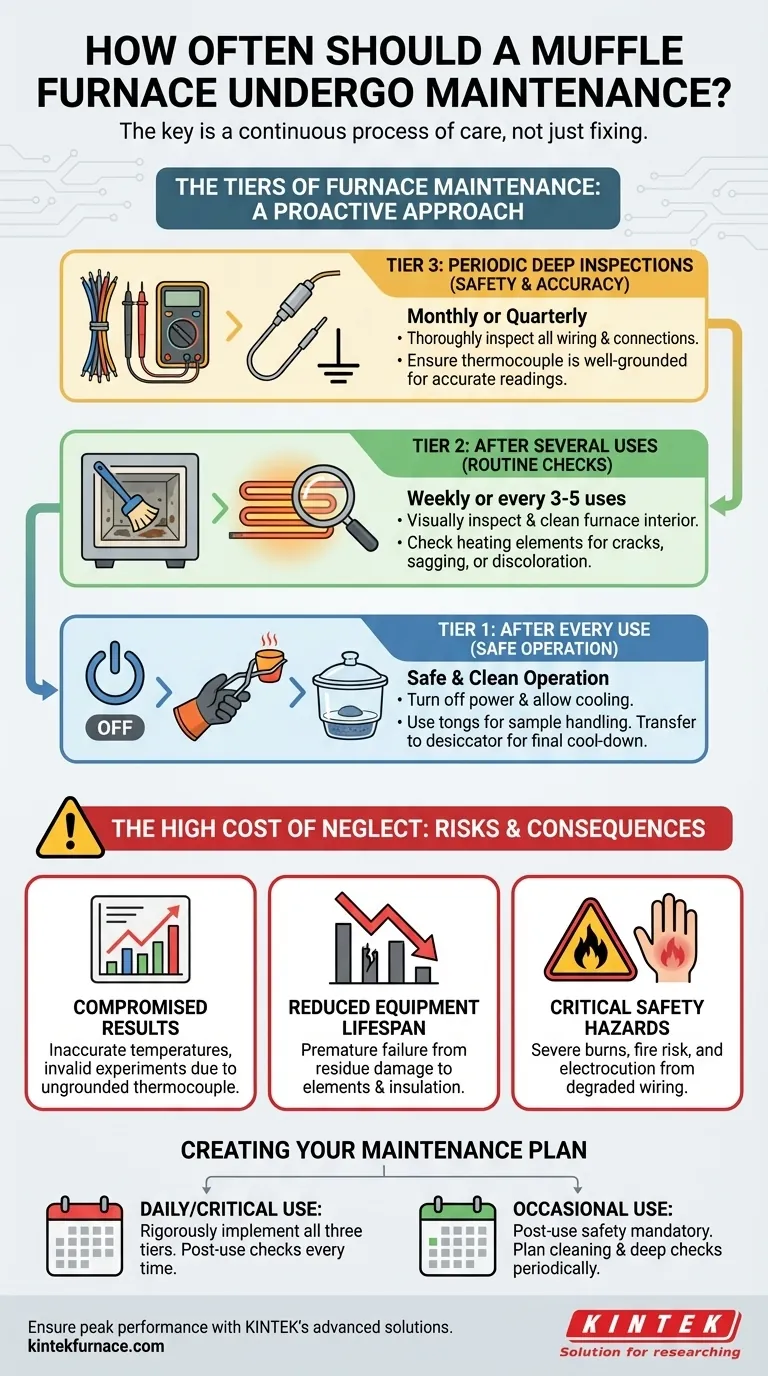

The short answer is that a muffle furnace does not have a single, fixed maintenance schedule. Instead, its upkeep is a continuous process divided into different tiers: minor checks and cleaning after every few uses, and more thorough inspections of electrical components performed periodically to ensure safety and accuracy.

The key to muffle furnace longevity is shifting from a mindset of "how often should I fix it?" to one of "how can I consistently care for it?" Proactive, tiered maintenance—from daily operational checks to periodic deep inspections—is far more effective than waiting for a problem to arise.

The Tiers of Furnace Maintenance

Effective maintenance isn't a single event but a series of checks performed at different frequencies. This approach ensures safety, operational accuracy, and protects your investment.

Tier 1: After Every Use

This tier focuses on safe and clean operation, which is the first line of defense against long-term problems.

After your process is complete, turn off the power and allow the sample to cool inside the furnace before removal.

When removing samples, always open the furnace door carefully. Use appropriate tools like tongs to handle the still-hot crucible, transferring it to a desiccator for final cooling to prevent burns and thermal shock.

Tier 2: After Several Uses

These routine checks should be done regularly, perhaps weekly or after every 3-5 uses, depending on your throughput.

Visually inspect the furnace interior for any residue, spillage, or debris. Cleaning the furnace chamber when it is dirty is critical to prevent sample contamination and damage to the heating elements.

Briefly check the heating elements for any visible signs of cracking, sagging, or discoloration, which could indicate impending failure.

Tier 3: Periodic Deep Inspections

These checks are less frequent but are vital for ensuring accuracy and electrical safety. The frequency depends on usage but can be considered on a monthly or quarterly basis.

Thoroughly inspect all wiring on both the furnace and its controller. Look for frayed insulation, loose connections, or signs of overheating.

Check the thermocouple, which is the sensor that measures temperature. Ensure it is well-grounded to the furnace to prevent measurement errors and provide accurate readings. A poorly grounded thermocouple is a common source of inaccurate results.

The High Cost of Neglect

Skipping these maintenance steps can seem like a time-saver, but it introduces significant risks and long-term costs that far outweigh the effort of proactive care.

Compromised Results

The most immediate impact of poor maintenance is on your data. An ungrounded thermocouple can report incorrect temperatures, rendering your experiments or processes invalid.

Reduced Equipment Lifespan

Residue left inside the furnace can attack the heating elements and insulation, leading to premature and costly failure. Ignoring early signs of element damage will eventually lead to a full breakdown.

Critical Safety Hazards

Failing to follow proper cooling and handling procedures creates a direct risk of severe burns. Furthermore, degraded electrical wiring is a significant fire and electrocution hazard that must be addressed promptly.

Creating Your Maintenance Plan

Your ideal schedule depends on how you use the furnace. Use the following guidelines to establish a practical routine for your lab.

- If you use the furnace daily for critical processes: Implement all three tiers rigorously. Perform post-use checks every time, clean the interior weekly, and schedule a monthly deep inspection of wiring and the thermocouple.

- If you use the furnace occasionally or for non-critical work: The post-use procedures are still mandatory for safety. Plan to clean the chamber and inspect elements after every few cycles, and perform a deep electrical check at least quarterly.

Ultimately, consistent attention is the best strategy for keeping your muffle furnace safe, accurate, and reliable for years to come.

Summary Table:

| Maintenance Tier | Frequency | Key Actions |

|---|---|---|

| After Every Use | After each operation | Turn off power, allow cooling, use tongs for sample handling, transfer to desiccator |

| After Several Uses | Weekly or every 3-5 uses | Clean furnace interior, inspect heating elements for damage |

| Periodic Deep Inspections | Monthly or quarterly | Check wiring and thermocouple for safety and accuracy |

Ensure your muffle furnace operates at peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique needs. Contact us today to discuss how our tailored furnace solutions can enhance your lab's safety, accuracy, and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis