Inline Plasma Enhanced Chemical Vapor Deposition (PECVD) equipment is primarily used in solar manufacturing to deposit critical thin-film layers that passivate the silicon surface and minimize light reflection. specifically, this equipment applies Silicon Nitride (SiNx) and Aluminum Oxide (AlOx) layers, as well as doped amorphous silicon (a-Si:H) for advanced contact structures, ensuring high efficiency at mass-production scales.

Core Takeaway Inline PECVD is the industry standard for applying multifunctional layers that simultaneously protect the solar cell electrically (passivation) and optically (anti-reflection). Its ability to drive chemical reactions via plasma rather than thermal heat allows for high-density film deposition without damaging temperature-sensitive silicon wafers.

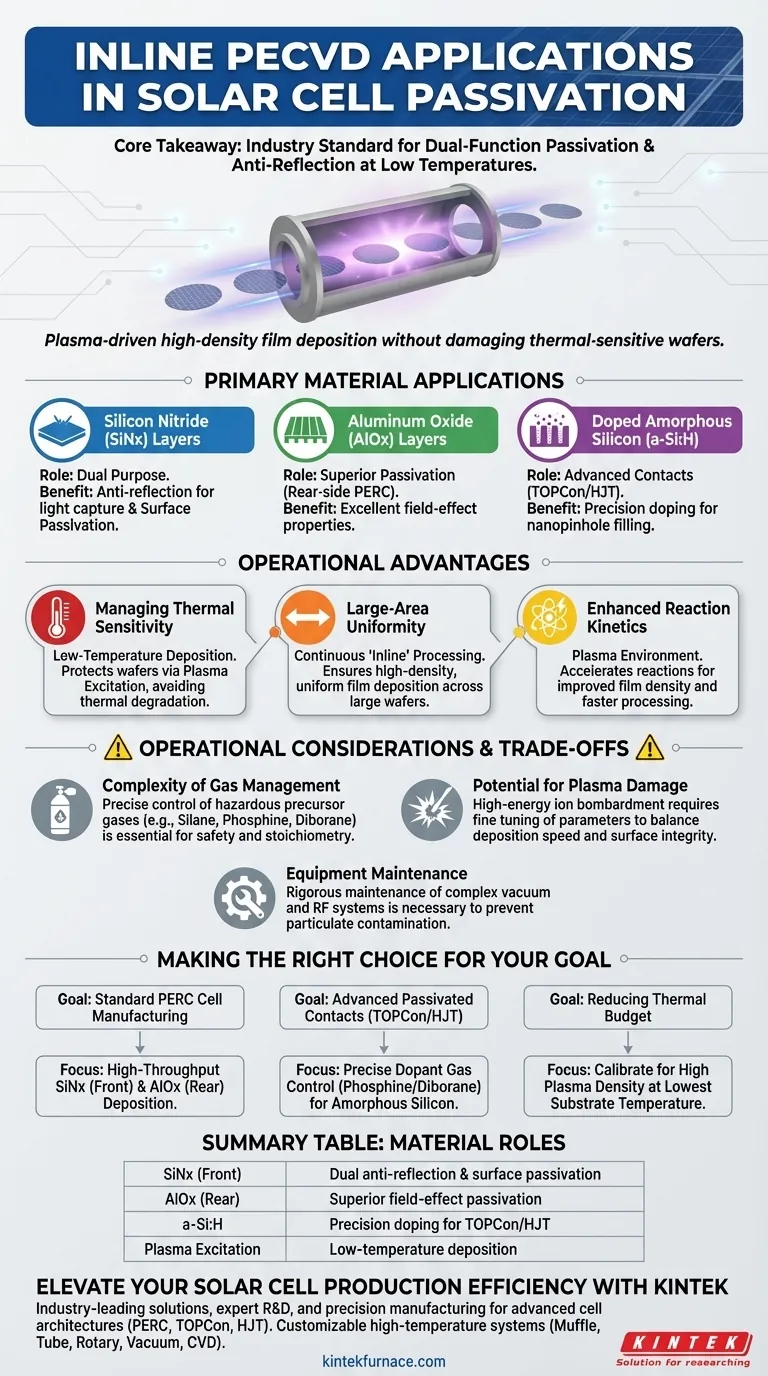

Primary Material Applications in Passivation

The primary function of inline PECVD in solar production is the deposition of specific materials that reduce electron recombination on the silicon surface.

Silicon Nitride (SiNx) Layers

This is the most common application in the industry. SiNx serves a dual purpose: it acts as an anti-reflection coating to capture more light and provides excellent surface passivation to retain electrical charge.

Aluminum Oxide (AlOx) Layers

Inline PECVD is also used to deposit Aluminum Oxide. This material provides superior passivation, particularly for the rear side of modern solar cells (such as PERC cells), due to its field-effect passivation properties.

Doped Amorphous Silicon (a-Si:H)

For advanced cell architectures, PECVD systems deposit doped amorphous silicon onto dielectric layers. By controlling gases like Phosphine or Diborane, the system ensures the material fills nanopinhole templates, creating effective passivated contacts.

The Operational Advantages of Inline PECVD

Understanding why this specific equipment is used over other deposition methods reveals the "deep need" for efficiency and quality in solar manufacturing.

Managing Thermal Sensitivity

Standard Chemical Vapor Deposition (CVD) often requires high temperatures that can degrade solar wafers. PECVD uses plasma excitation to initiate chemical reactions, allowing for the deposition of high-quality films at significantly lower temperatures.

Large-Area Uniformity

The "Inline" aspect of the equipment allows for the processing of large surface areas continuously. This system achieves high-density thin film deposition that is uniform across the entire wafer, which is critical for maintaining consistent module power output.

Enhanced Reaction Kinetics

The plasma environment creates essential electrons, ions, and neutral radicals. This accelerates reaction kinetics, leading to improved film density and faster processing times compared to non-plasma methods.

Operational Considerations and Trade-offs

While inline PECVD is highly effective, it introduces specific complexities that manufacturers must manage.

Complexity of Gas Management

The process relies on precise flows of reactive and often hazardous precursor gases, such as Silane, Phosphine, and Diborane. Safe handling and precise mass flow control are non-negotiable requirements for facility safety and film stoichiometry.

Potential for Plasma Damage

While plasma enables low-temperature processing, high-energy ion bombardment can inadvertently damage the silicon lattice surface. Process parameters must be finely tuned to balance deposition speed with surface integrity.

Equipment Maintenance

Inline vacuum systems with RF power sources are complex. They require rigorous maintenance schedules to prevent particulate contamination, which can create shunts or defects in the passivation layers.

Making the Right Choice for Your Goal

The specific configuration of PECVD equipment depends heavily on the cell architecture you are manufacturing.

- If your primary focus is standard PERC cell manufacturing: Prioritize equipment optimized for high-throughput Silicon Nitride (front) and Aluminum Oxide (rear) deposition.

- If your primary focus is advanced passivated contacts (TOPCon/HJT): Select systems with precise dopant gas control (Phosphine/Diborane) capable of filling nanopinhole structures with amorphous silicon.

- If your primary focus is reducing thermal budget: Ensure the PECVD system is calibrated for high plasma density to maximize film quality at the lowest possible substrate temperature.

Inline PECVD is not just a coating tool; it is the critical step that transforms a raw silicon wafer into a high-efficiency energy-harvesting device.

Summary Table:

| Material | Application Role | Key Benefit |

|---|---|---|

| Silicon Nitride (SiNx) | Front-side coating | Dual anti-reflection & surface passivation |

| Aluminum Oxide (AlOx) | Rear-side (PERC) | Superior field-effect passivation |

| Amorphous Silicon | Advanced contacts | Precision doping for TOPCon/HJT structures |

| Plasma Excitation | Process control | Low-temperature deposition to protect wafers |

Elevate Your Solar Cell Production Efficiency

Transitioning to advanced cell architectures like PERC, TOPCon, or HJT requires the highest standards in thin-film deposition. KINTEK provides industry-leading solutions backed by expert R&D and precision manufacturing.

Our extensive range of laboratory and industrial high-temperature systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—are fully customizable to meet your unique passivation and thermal processing needs.

Ready to optimize your solar manufacturing throughput? Contact our technical experts today to discuss how our tailored furnace and deposition solutions can enhance your material performance.

Visual Guide

References

- Pradeep Padhamnath, Armin G. Aberle. Investigation of Contact Properties and Device Performance for Bifacial Double-Side Textured Silicon Solar Cells With Polysilicon Based Passivating Contacts. DOI: 10.52825/siliconpv.v2i.1295

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does the method of operation in PECVD work? Unlock Low-Temperature Thin Film Deposition

- What are the characteristics of the vacuum chamber in PECVD equipment? Key Features for Superior Thin Film Deposition

- What simulation tools are used to enhance PECVD processes? Discover Multi-Physics Suites for Precision

- What is the function of PECVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How can PECVD process parameters be optimized? Master Film Quality and Deposition Efficiency

- How does pressure affect the PECVD process? Optimize Film Quality and Deposition Rates

- What are some advantages of using PECVD over traditional CVD methods? Unlock Low-Temperature Thin Film Deposition

- What types of materials can be deposited using the PECVD process? Explore Versatile Low-Temperature Film Deposition