In physics research, a laboratory tube furnace is an essential instrument for creating precisely controlled, high-temperature environments. Its core applications revolve around synthesizing novel materials and measuring how the fundamental physical properties of matter change in response to extreme heat, often within a specific atmospheric or vacuum condition.

A tube furnace's value in physics lies not just in its ability to heat, but in its capacity to create a highly isolated and programmable thermal environment. This control is the key that unlocks the ability to both create new materials and precisely measure their response to temperature, forming a feedback loop of discovery.

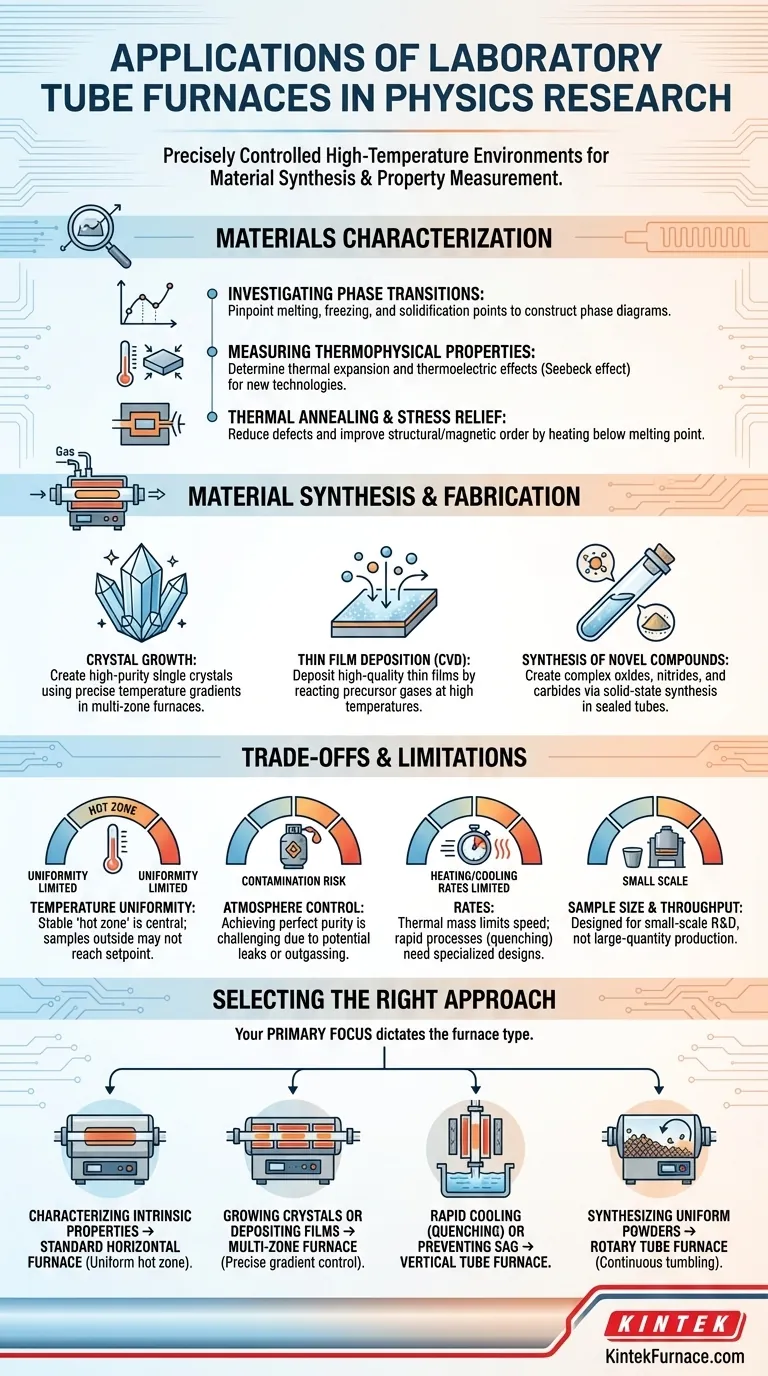

Core Applications in Materials Characterization

The primary use of a tube furnace in physics is to probe the behavior of materials. By precisely controlling the temperature profile, researchers can isolate and measure specific properties that are critical for both fundamental science and applied technology.

Investigating Phase Transitions

A furnace allows for the direct observation of phase changes. By slowly ramping the temperature, researchers can pinpoint the exact melting, freezing, and solidification points of a material, which is fundamental to constructing its phase diagram.

Measuring Thermophysical Properties

Many critical physical properties are temperature-dependent. Tube furnaces are used to measure a material's thermal expansion (how its size changes with heat) and its thermoelectric properties (like the Seebeck effect), which are crucial for developing new energy harvesting and cooling technologies.

Thermal Annealing and Stress Relief

Heating a material to a specific temperature below its melting point and holding it there can significantly alter its properties. This process, known as annealing, is used to reduce internal stresses, remove crystal defects, and improve the material's structural or magnetic order, making it more suitable for precise measurements.

Applications in Material Synthesis and Fabrication

Beyond characterization, tube furnaces are miniature factories for creating the very materials physicists want to study. This synthesis capability is what drives much of modern condensed matter physics and materials science.

Crystal Growth

Creating large, high-purity single crystals is essential for measuring the intrinsic properties of a material without interference from grain boundaries. Tube furnaces with multiple heating zones can create precise temperature gradients necessary to grow crystals from a melt, solution, or vapor.

Thin Film Deposition (CVD)

Chemical Vapor Deposition (CVD) is a process where a substrate is exposed to volatile precursor gases inside the furnace tube. The high temperature causes the gases to react or decompose, depositing a high-quality thin film onto the substrate, which is a foundational technique in semiconductor physics and optics.

Synthesis of Novel Compounds

Tube furnaces are workhorses for solid-state synthesis. By sealing reactants inside a quartz or alumina tube (often under vacuum or an inert atmosphere) and heating them for extended periods, researchers can create entirely new compounds like complex oxides, nitrides, and carbides that may exhibit unique electronic or magnetic properties.

Understanding the Trade-offs and Limitations

While powerful, a tube furnace is not without its operational constraints. Acknowledging these is crucial for designing a successful experiment and interpreting results accurately.

Temperature Uniformity

The temperature inside the tube is not perfectly uniform. There is a central "hot zone" where the temperature is stable and matches the setpoint. The length of this zone is a critical specification, as samples placed outside of it will not experience the intended temperature.

Atmosphere Control

While a tube furnace allows for controlled atmospheres (e.g., argon, nitrogen, vacuum), achieving perfect purity can be challenging. Minor leaks or outgassing from the tube itself can introduce contaminants that may affect sensitive materials or reactions.

Heating and Cooling Rates

The thermal mass of the furnace insulation and heating elements limits how quickly the temperature can be changed. Processes requiring extremely rapid heating or cooling (quenching) may necessitate specialized furnace designs, such as a vertical furnace that allows samples to be dropped out of the hot zone.

Sample Size and Throughput

Laboratory tube furnaces are, by design, intended for small-scale research and development. They are not suitable for processing large quantities of material, which would require an industrial-scale furnace.

Selecting the Right Approach for Your Goal

The specific application dictates the type of furnace and experimental setup required. Your choice should be guided by your primary experimental objective.

- If your primary focus is characterizing intrinsic properties: A standard horizontal furnace with a well-defined, uniform hot zone is the most effective tool.

- If your primary focus is growing single crystals or depositing films: A multi-zone furnace that allows for precise control over the temperature gradient is essential.

- If your primary focus involves rapid cooling (quenching) or preventing sample sag at high temperatures: A vertical tube furnace, which allows a sample to be dropped into a quenching medium, is necessary.

- If your primary focus is synthesizing uniform powders: A rotary tube furnace, which continuously tumbles the material during heating, is the specialized instrument for the job.

Ultimately, viewing the tube furnace as a highly adaptable environmental chamber is the key to unlocking its full potential in physics research.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Materials Characterization | Phase transition studies, thermophysical property measurement, thermal annealing |

| Material Synthesis | Crystal growth, thin film deposition (CVD), synthesis of novel compounds |

| Limitations | Temperature uniformity issues, atmosphere control challenges, limited heating/cooling rates, small sample size |

| Selection Guide | Standard for characterization, multi-zone for crystals/films, vertical for quenching, rotary for powders |

Ready to elevate your physics research with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're synthesizing novel materials or characterizing physical properties. Contact us today to discuss how our solutions can drive your discoveries forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision