In short, sintered dental zirconia possesses exceptional aging resistance and high flexural strength, making it one of the most durable and reliable materials in modern restorative dentistry. Its unique molecular structure actively combats degradation over time, while its strength, ranging from 800 to 1200 MPa, is sufficient for the most demanding dental applications.

The core takeaway is that sintered zirconia's value lies not just in its immediate high strength, but in its proven ability to maintain that strength over many years. This is achieved through a specialized composition that resists the low-temperature degradation common in oral environments.

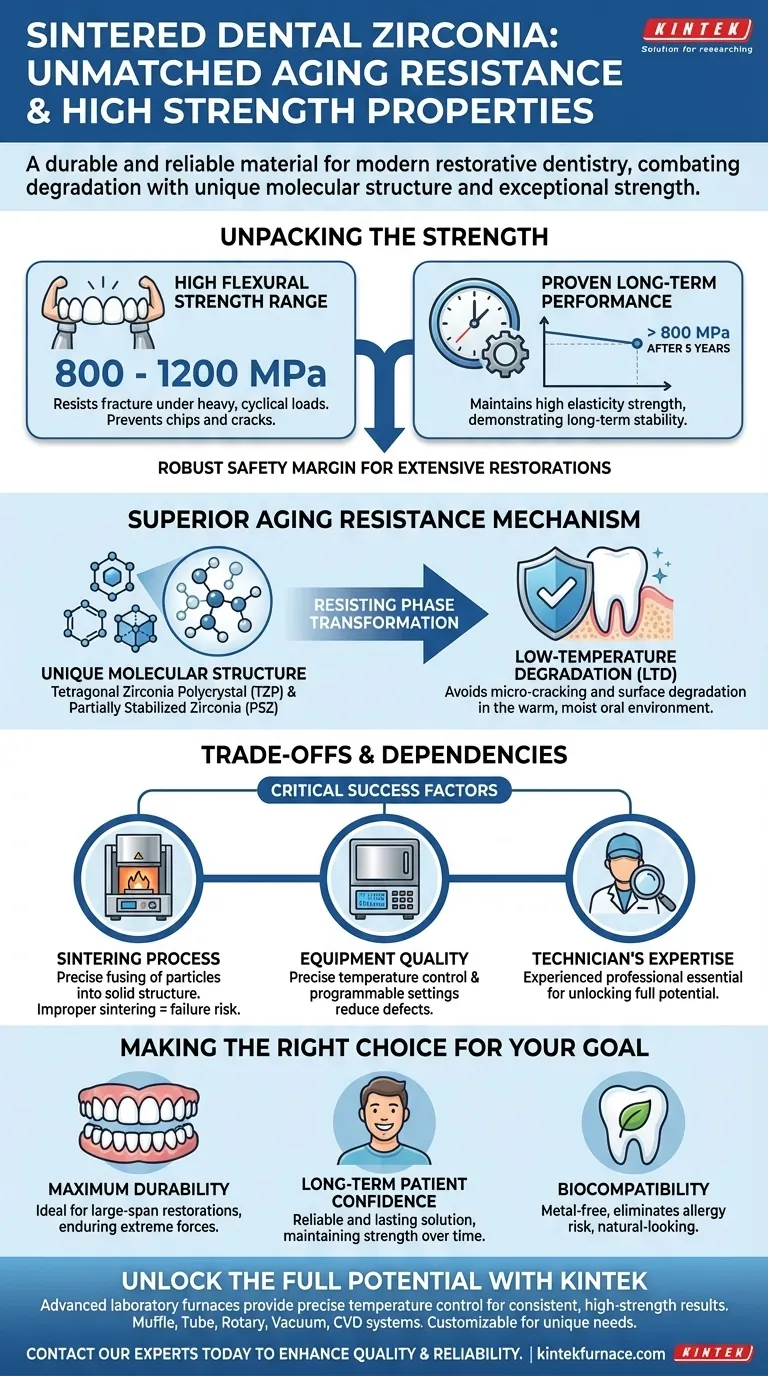

Unpacking the Strength of Sintered Zirconia

The mechanical properties of sintered zirconia are the foundation of its clinical success. These properties ensure restorations can withstand the significant forces of chewing without failing.

The High Flexural Strength Range

Sintered dental zirconia exhibits a bending or flexural strength that typically ranges between 800 and 1200 MPa. This high value is critical, as it allows the material to resist fracture under the heavy, cyclical loads experienced in the mouth.

Proven Long-Term Performance

Crucially, this strength is not temporary. Studies and clinical use have shown that the material maintains a flexural elasticity strength greater than 800 MPa even after five years of service. This demonstrates its long-term stability and reliability.

Preventing Chips and Cracks

This impressive strength range provides a robust safety margin that helps prevent chips and cracks both during the dental lab's processing phase and throughout its use by the patient. This resilience makes it a suitable material for extensive restorations, including full-mouth and implant-supported bridges.

The Mechanism Behind Its Superior Aging Resistance

"Aging" in this context refers to a material's response to the warm, moist environment of the mouth over time, a process technically known as low-temperature degradation (LTD). Zirconia is engineered to resist this.

A Unique Molecular Structure

Sintered dental zirconia's superior aging resistance comes from its unique combination of Tetragonal Zirconia Polycrystal (TZP) and Partially Stabilized Zirconia (PSZ) molecules. This structure is specifically designed to be highly stable.

Resisting Phase Transformation

This specialized composition effectively withstands the material's natural tendency to undergo a phase transformation. By resisting this change, the material avoids the micro-cracking and surface degradation that could otherwise compromise its strength over time.

Understanding the Trade-offs and Dependencies

The exceptional properties of zirconia are not automatic. They are the direct result of a highly controlled and precise manufacturing process. The final quality is highly dependent on both the equipment and the technician.

The Critical Role of the Sintering Process

Sintering is the furnace-based process that fuses zirconia particles into a solid, dense structure. The success of this procedure is paramount. Improper sintering can lead to a restoration that fails to meet its strength specifications, increasing the risk of premature failure.

Dependence on Equipment Quality

High-quality outcomes require high-quality tools. Modern sintering furnaces provide precise temperature control and programmable settings to ensure each restoration is sintered under optimal conditions. This reduces the likelihood of fractures, chipping, and breakage.

The Technician's Expertise is Non-Negotiable

Ultimately, the quality of a sintered zirconia restoration is highly dependent on the competence of the dental technician. An experienced professional using innovative equipment is essential to unlock the material's full potential for strength and longevity.

Making the Right Choice for Your Goal

Selecting sintered zirconia is a step toward a durable and aesthetic restoration. How you apply it depends on the clinical objective.

- If your primary focus is maximum durability for large-span restorations: Its high flexural strength (800-1200 MPa) makes it the ideal choice for full-mouth and implant-supported bridges that must endure extreme forces.

- If your primary focus is long-term patient confidence: Its proven aging resistance, with strength maintained above 800 MPa after five years, ensures a reliable and lasting solution.

- If your primary focus is biocompatibility: As a metal-free material, it eliminates the risk of metal allergies while providing a strong, fully functional, and natural-looking tooth replacement.

This combination of immediate strength and long-term stability is why sintered zirconia has become a trusted cornerstone of restorative dentistry.

Summary Table:

| Property | Key Metric | Clinical Significance |

|---|---|---|

| Flexural Strength | 800 - 1200 MPa | Withstands high chewing forces, prevents chips and cracks. |

| Aging Resistance | > 800 MPa after 5 years | Maintains strength and integrity in the oral environment over time. |

| Material Structure | Tetragonal Zirconia Polycrystal (TZP) | Resists low-temperature degradation (LTD) and phase transformation. |

Unlock the full potential of sintered zirconia in your lab.

The exceptional properties of zirconia are only realized through precise sintering. KINTEK's advanced laboratory furnaces provide the exact temperature control and programmable profiles required for consistent, high-strength results. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Contact our experts today to discuss how our sintering solutions can enhance the quality and reliability of your dental restorations.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations