At its core, the primary advantage of an inert atmosphere furnace is its ability to prevent unwanted chemical reactions, chiefly oxidation, during high-temperature processing. This fundamental capability leads to significantly improved product quality, enhanced material integrity, and greater overall process efficiency by eliminating the need for secondary cleaning or corrective treatments.

The true value of an inert atmosphere furnace extends beyond simply preventing rust. It provides a level of environmental control that is essential for creating materials with precise, repeatable properties, making it an indispensable tool for advanced manufacturing and research.

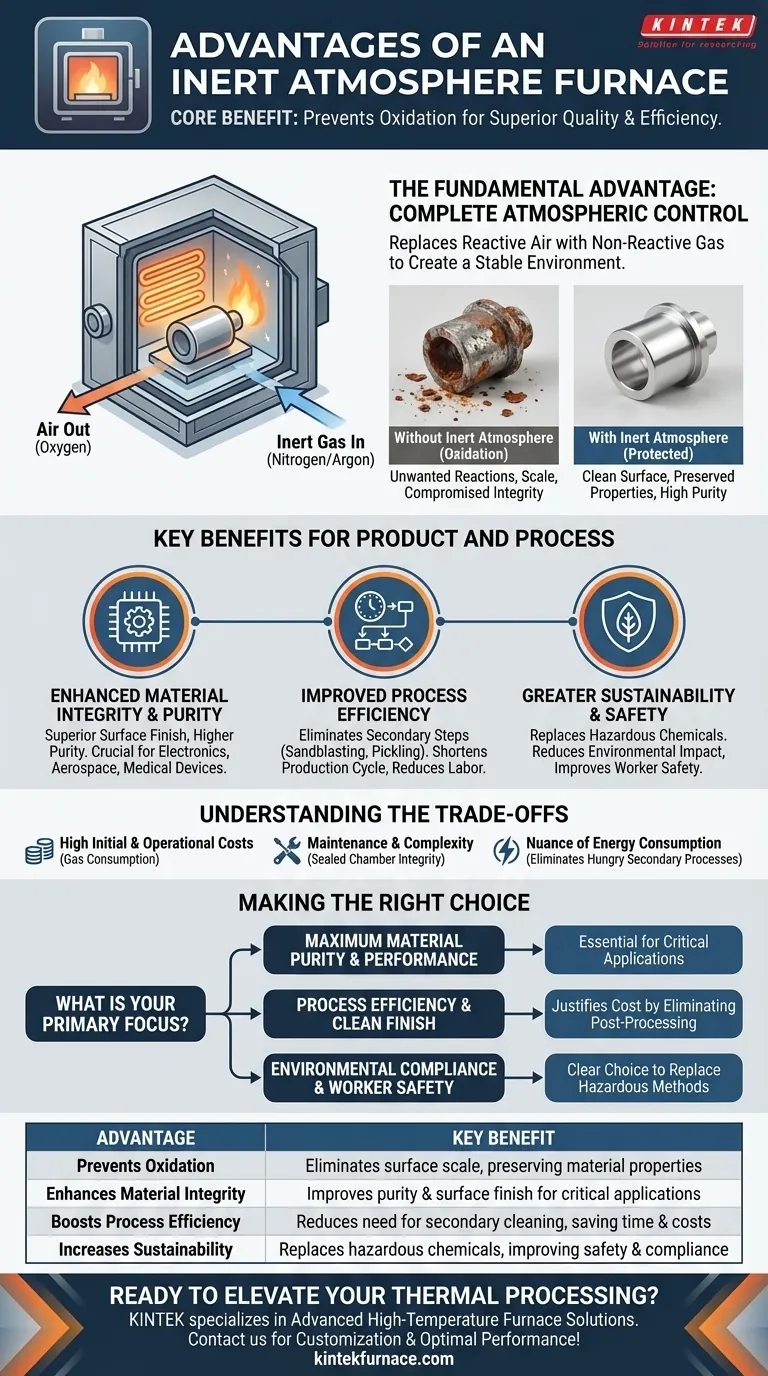

The Fundamental Advantage: Complete Atmospheric Control

An inert atmosphere furnace operates by replacing the reactive air inside its heating chamber with a non-reactive (inert) gas, typically nitrogen or argon. This creates a chemically stable environment, which is the source of all its benefits.

Preventing Oxidation and Unwanted Reactions

At elevated temperatures, most metals readily react with oxygen in the air. This reaction, known as oxidation, forms a layer of scale on the material's surface, which can compromise its dimensions, finish, and structural properties.

Inert atmospheres prevent this entirely. By displacing oxygen, the furnace ensures the material's surface remains clean and unaltered throughout the heating and cooling cycle. This is critical for processes like brazing, sintering, and bright annealing.

How an Inert Atmosphere Works

The furnace consists of a tightly sealed chamber connected to a gas supply system. Before the heating cycle begins, the chamber is purged with an inert gas to flush out all the ambient air.

A continuous, low-pressure flow of this gas is maintained during operation to prevent any air from leaking in. This ensures the part is only ever exposed to the non-reactive gas, preserving its chemical and physical integrity.

Key Benefits for Product and Process

Controlling the atmosphere unlocks several significant advantages that impact everything from product quality to operational sustainability.

Enhanced Material Integrity and Purity

By eliminating reactions with atmospheric gases, you achieve a product with a superior surface finish and higher purity. This is crucial for applications in electronics, aerospace, and medical devices where even microscopic contamination can lead to component failure. The material's intrinsic properties, such as strength and conductivity, are preserved.

Improved Process Efficiency

Materials processed in a normal atmosphere furnace often require secondary steps like sandblasting, grinding, or acid pickling to remove the oxide scale.

An inert furnace produces parts that are clean and bright straight out of the furnace, completely eliminating these costly and time-consuming post-treatment steps. This shortens the overall production cycle and reduces labor costs.

Greater Sustainability and Safety

Traditionally, some heat-treating processes relied on toxic materials like cyanide salts to protect parts from oxidation. Inert atmosphere furnaces provide a modern, safer alternative.

They eliminate the use of hazardous chemicals and the challenges of disposing of contaminated waste. This reduces environmental impact, lowers compliance risks, and creates a much safer working environment.

Understanding the Trade-offs

While powerful, this technology is not without its challenges. Objectivity requires acknowledging the associated costs and complexities.

High Initial and Operational Costs

Inert atmosphere furnaces are more complex and therefore more expensive than their standard atmosphere counterparts. Furthermore, the continuous consumption of high-purity inert gas represents a significant ongoing operational cost.

Maintenance and Operational Complexity

Maintaining the integrity of the sealed chamber is critical. Any leaks will compromise the inert environment and defeat the purpose of the furnace. This requires diligent maintenance, sophisticated monitoring systems, and well-trained operators.

The Nuance of Energy Consumption

The furnace itself can be energy-intensive due to the high temperatures required for many heat treatments. However, by eliminating energy-hungry secondary processes, the total energy consumption for the entire manufacturing workflow is often reduced, making the overall process more efficient.

Making the Right Choice for Your Application

An inert atmosphere furnace is a strategic investment. The decision to use one should be based on a clear understanding of your final goal.

- If your primary focus is maximum material purity and performance: The furnace is essential for achieving the uncontaminated, high-integrity surfaces required in medical, aerospace, or electronics manufacturing.

- If your primary focus is process efficiency and a clean finish: The technology justifies its cost by eliminating entire post-processing steps, directly improving throughput and reducing labor for parts requiring a bright finish.

- If your primary focus is environmental compliance and worker safety: This furnace is the clear choice to replace older, hazardous heat treatment methods and significantly reduce your operation's environmental footprint.

Ultimately, choosing an inert atmosphere furnace is a decision to prioritize control and precision in your thermal processing.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Oxidation | Eliminates surface scale, preserving material properties |

| Enhances Material Integrity | Improves purity and surface finish for critical applications |

| Boosts Process Efficiency | Reduces need for secondary cleaning, saving time and costs |

| Increases Sustainability | Replaces hazardous chemicals, improving safety and compliance |

Ready to elevate your thermal processing with precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Inert Atmosphere Furnaces, designed to meet the unique needs of industries like aerospace, electronics, and medical devices. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to ensure optimal performance for your specific applications. Contact us today to discuss how our expertise can enhance your material integrity and streamline your operations!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity