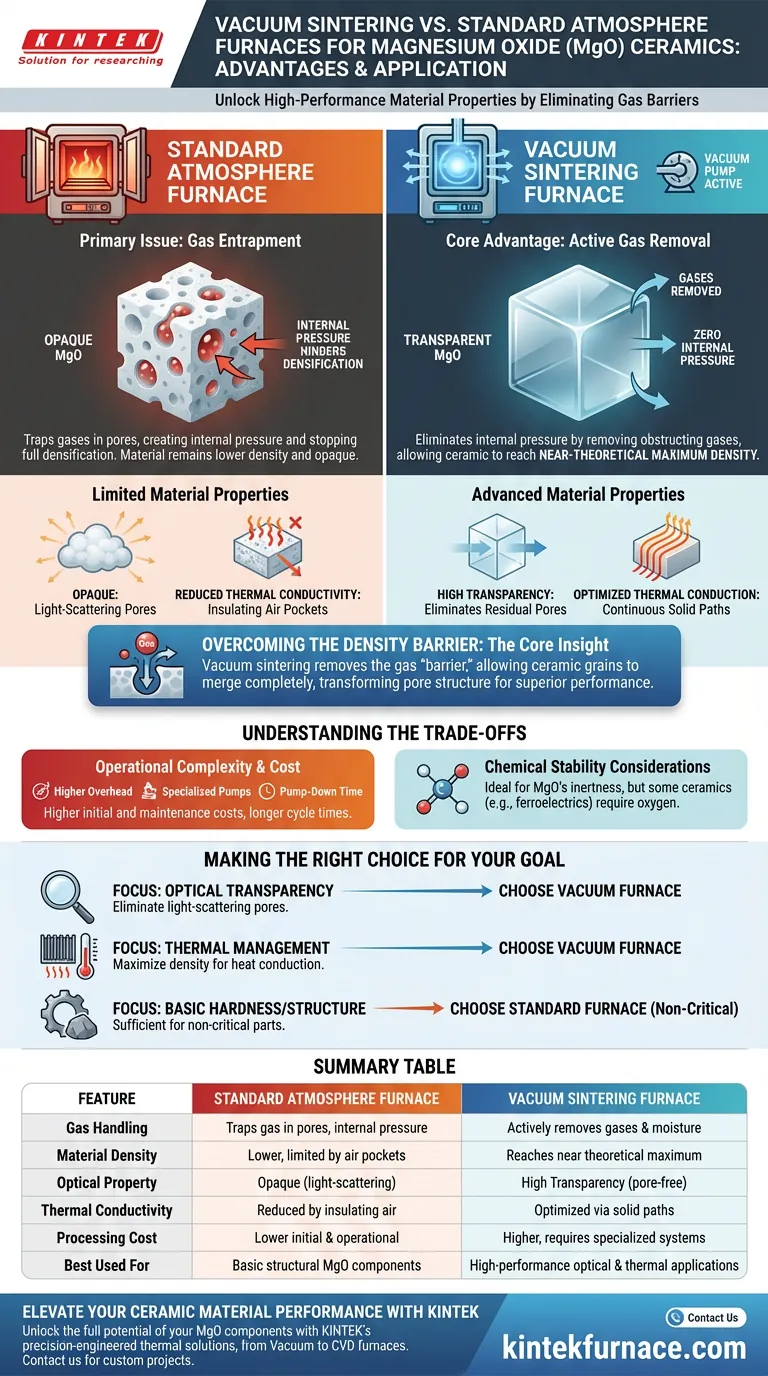

The primary advantage of using a vacuum sintering furnace for Magnesium Oxide (MgO) is the active removal of gases that otherwise hinder the densification process. While standard atmosphere furnaces often trap gases inside the material, a vacuum environment eliminates internal pressure, allowing the ceramic to achieve a microscopic structure that closely approaches its theoretical density.

The Core Insight Vacuum sintering does not just heat the material; it fundamentally changes the pore structure. By removing obstructing gases, it eliminates the internal pressure that fights against shrinkage. For MgO specifically, this is the deciding factor between producing a standard opaque ceramic and a high-performance, transparent material with superior thermal conductivity.

Overcoming the Density Barrier

Eliminating Internal Gas Pressure

In a standard atmosphere furnace, gas molecules can become trapped inside the ceramic's pores as the material shrinks.

This trapped gas creates internal pressure that pushes back against the sintering force, effectively stopping the material from becoming fully dense. A vacuum environment removes these gases, removing the resistance to shrinkage.

Removing Adsorbed Volatiles

Raw ceramic powders often contain adsorbed gases or moisture on their surface.

During the initial heating stages, a vacuum furnace effectively extracts these volatiles. This prevents the formation of closed pores later in the process, ensuring the final structure is solid rather than sponge-like.

Reaching Theoretical Density

The ultimate goal of sintering MgO is to eliminate porosity entirely.

By removing the gas "barrier," the ceramic grains can merge more completely. This results in a final product that possesses a density nearly identical to the material's theoretical maximum.

Unlocking Advanced Material Properties

Achieving Optical Transparency

The most specific benefit for MgO mentioned in technical literature is transparency.

Residual pores in a ceramic act as light-scattering centers, making the material opaque. By virtually eliminating these residual pores, vacuum sintering allows light to pass through the material, which is essential for optical applications.

Optimizing Thermal Conduction

Air is a thermal insulator. Therefore, any microscopic air pockets left inside the ceramic reduce its ability to transfer heat.

Vacuum sintering creates continuous, solid thermal conduction paths throughout the material. This significantly enhances the thermal conductivity of the final MgO component.

Understanding the Trade-offs

Operational Complexity and Cost

While vacuum systems offer purity and density, they come with higher overhead.

Compared to low-vacuum or standard atmosphere furnaces, high-vacuum systems are more expensive to operate and maintain. They also require pump-down time, which can lengthen the overall processing cycle compared to simple open-air firing.

Chemical Stability Considerations

Vacuum sintering is not universally superior for all ceramic types; it depends on the chemistry.

For example, certain oxide ceramics (like BCZT) require an oxygen-rich atmosphere to reduce oxygen vacancies and maintain piezoelectric properties. However, for MgO, where the goal is often inertness and physical density rather than ferroelectric manipulation, vacuum remains the superior choice.

Making the Right Choice for Your Goal

If you are deciding between a standard atmosphere furnace and a vacuum system for your MgO project, consider your end requirements:

- If your primary focus is Optical Transparency: You must use a vacuum furnace to eliminate the residual pores that scatter light and cause opacity.

- If your primary focus is Thermal Management: A vacuum environment is required to maximize density and ensure unobstructed thermal conduction paths.

- If your primary focus is Basic Hardness/Structure: A vacuum furnace will generally yield higher strength and hardness, though a standard furnace may suffice for non-critical structural parts.

Summary: For high-performance Magnesium Oxide ceramics, the vacuum furnace is not a luxury but a necessity to remove the physical gas barriers that prevent full density and transparency.

Summary Table:

| Feature | Standard Atmosphere Furnace | Vacuum Sintering Furnace |

|---|---|---|

| Gas Handling | Traps gas in pores, creating internal pressure | Actively removes gases and volatile moisture |

| Material Density | Lower; limited by trapped air pockets | Reaches near theoretical maximum density |

| Optical Property | Opaque (due to light-scattering pores) | High Transparency (eliminates residual pores) |

| Thermal Conductivity | Reduced by insulating air pockets | Optimized via continuous solid conduction paths |

| Processing Cost | Lower initial and operational overhead | Higher; requires specialized pumping systems |

| Best Used For | Basic structural MgO components | High-performance optical and thermal applications |

Elevate Your Ceramic Material Performance with KINTEK

Unlock the full potential of your Magnesium Oxide components with precision-engineered thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of high-temperature laboratory systems, including Vacuum, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to meet your unique sintering requirements.

Whether you are aiming for theoretical density or optical transparency, our technical experts are ready to design the perfect furnace for your lab. Contact KINTEK today to discuss your custom project and see how our advanced vacuum technology can transform your material outcomes.

Visual Guide

References

- Advanced Thermal Interface Materials: Insights into Low‐Temperature Sintering and High Thermal Conductivity of MgO. DOI: 10.1002/adma.202510237

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the key functions of a high-vacuum high-temperature testing machine? Evaluate UHTCMC Mechanical Reliability

- Why is a high-performance vacuum system critical for Gallium Sulfide crystal sealing? Ensure 10^-6 Torr Purity

- What are the steps involved in the vacuum sintering process? Master Precision and Purity for Superior Materials

- Why is an inert process atmosphere important in furnace brazing? Ensure Strong, Oxidation-Free Joints

- What are the chamber specifications of the vacuum furnace system? Ensure Purity and Safety in High-Temp Processing

- How does a sintering furnace work? Master the Process for Superior Material Properties

- What is the maximum vacuum level for a high vacuum furnace? Achieve Ultra-Clean Processing for Advanced Materials

- Why is a minimum cooling rate of 10°C/s required for 18CrNiMo7-6 steel? Achieve 64HRC Through High-Pressure Quenching