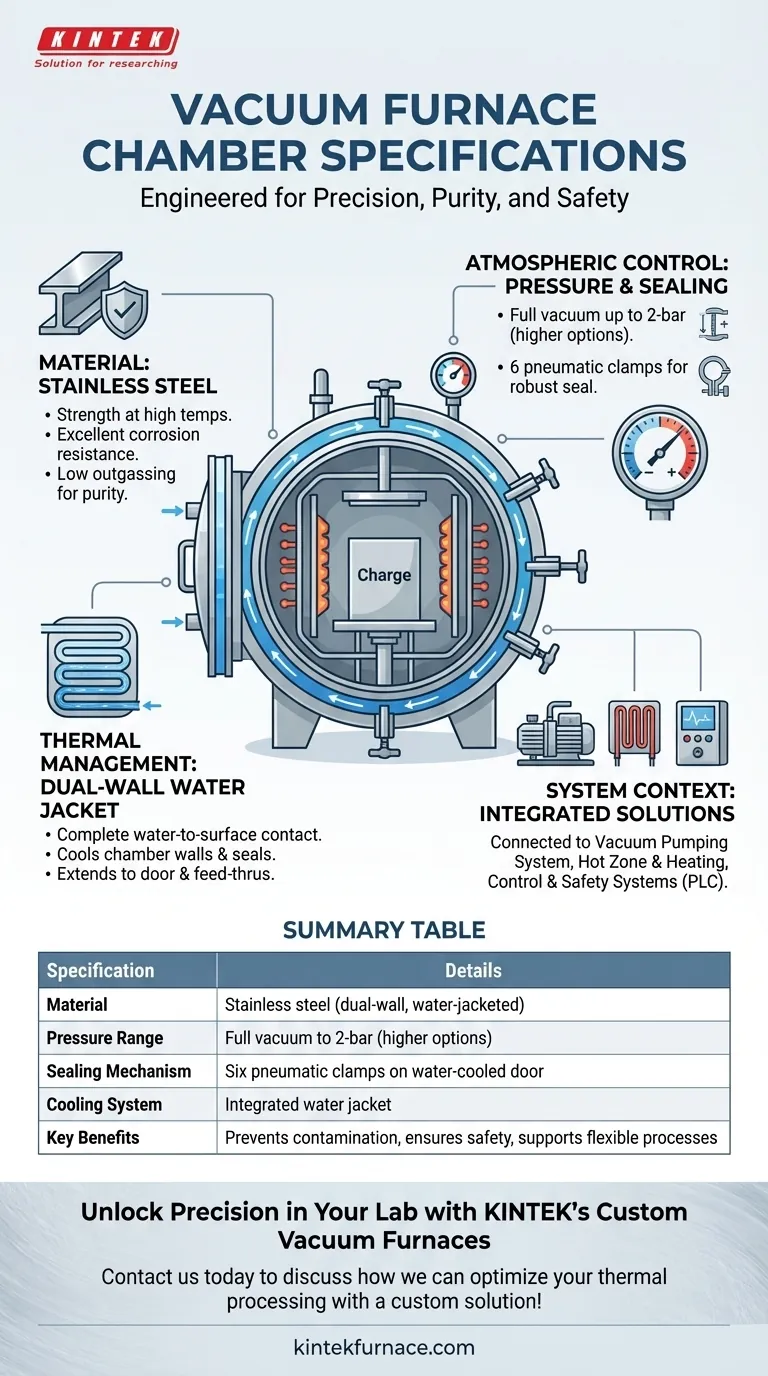

In summary, the vacuum furnace chamber is a dual-wall, water-jacketed vessel constructed entirely of stainless steel. It features a water-cooled door secured by six pneumatic clamps and is engineered to operate at pressures ranging from a full vacuum up to 2-bar, with options for higher pressures. The design prioritizes thermal management and atmospheric integrity to prevent contamination and ensure process safety.

The design of a vacuum furnace chamber is a deliberate exercise in control. Every feature, from the material choice to the cooling system, is engineered to isolate a high-temperature process from the outside world, ensuring the purity and integrity of the materials being treated.

Deconstructing the Chamber's Design

The chamber is the heart of the vacuum furnace, acting as a controlled environment. Its specifications are not arbitrary; they are directly tied to its function of withstanding extreme temperatures and pressure differentials while preventing contamination.

Material Selection: The Role of Stainless Steel

The entire chamber, including the door and water-jacketing, is built from stainless steel. This material is chosen for its strength at high temperatures and its excellent corrosion resistance.

More importantly, stainless steel is a preferred material for high-vacuum applications because it does not readily release trapped gases (outgassing), which would otherwise contaminate the vacuum environment and compromise the process.

Thermal Management: The Dual-Wall Water Jacket

The chamber features a dual-wall construction designed for complete water-to-surface contact. This water jacket is the furnace's primary cooling system.

While the interior "hot zone" reaches extreme temperatures, the circulating water keeps the chamber's structural walls cool. This prevents the steel from weakening, protects vacuum seals from failing, and ensures the safety of the operators and surrounding equipment.

This integrated cooling extends to the door and power feed-thrus, preventing any potential water leaks from entering the pristine vacuum environment.

Atmospheric Control: Pressure and Sealing

The chamber is designed to operate from a full vacuum up to a 2-bar positive pressure. This dual capability is critical for modern metallurgical processes.

A robust seal is essential. The system uses six clamp-over-center pneumatic clamps to lock the door. This mechanism provides the immense, evenly distributed force needed to maintain an airtight seal against both internal pressure and the powerful force of an external atmosphere during vacuum operation.

The Chamber's Core Function

Ultimately, the chamber is the vessel that houses the critical process components. Inside, you will find the heating elements (like graphite tubes), the thermal insulation (carbon felt), and the charge, which is the material being heat-treated. The chamber's job is to protect this entire process from the outside atmosphere.

Understanding the System Context

The chamber, while central, does not operate in isolation. It is one component in a larger, integrated system, and its design is dependent on the function of these other parts.

The Vacuum Pumping System

A dedicated vacuum system, composed of various pumps and valves, is responsible for evacuating the air from the chamber. The chamber's robust construction and tight seals are what allow this system to achieve and maintain the required low pressures.

The Hot Zone and Heating System

The heating elements and insulation located inside the chamber create the high-temperature environment. The chamber's cooling system works to contain this intense heat, protecting the vessel itself from the process it encloses.

The Control and Safety Systems

A programmable logic controller (PLC) and touch-panel interface manage every aspect of the furnace's operation. This includes controlling temperature ramps, vacuum set points, and gas backfills. The chamber's physical integrity is the foundation upon which these precise digital controls can reliably execute a process.

Key Takeaways for Evaluation

When assessing this or any vacuum furnace, understanding the chamber specifications allows you to match the equipment to your specific goals.

- If your primary focus is process purity: The all-stainless steel construction and high-vacuum design are engineered specifically to prevent atmospheric contamination of your materials.

- If your primary focus is operational safety: The comprehensive dual-wall water cooling for the chamber, door, and feed-thrus is the most critical feature for preventing structural failure and ensuring system reliability.

- If your primary focus is process flexibility: The ability to operate from a full vacuum to 2-bar positive pressure allows for a wide range of processes, from simple degassing to complex gas quenching and carburizing.

Ultimately, the chamber's specifications define its capacity to create and sustain a precisely controlled environment for high-value thermal processing.

Summary Table:

| Specification | Details |

|---|---|

| Material | Stainless steel (dual-wall, water-jacketed) |

| Pressure Range | Full vacuum up to 2-bar (higher options available) |

| Sealing Mechanism | Six pneumatic clamps on water-cooled door |

| Cooling System | Integrated water jacket for thermal management |

| Key Benefits | Prevents contamination, ensures safety, supports flexible processes |

Unlock Precision in Your Lab with KINTEK's Custom Vacuum Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need enhanced purity, safety, or process flexibility, our vacuum furnace chambers deliver reliable performance tailored to your goals.

Contact us today to discuss how we can optimize your thermal processing with a custom solution!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance