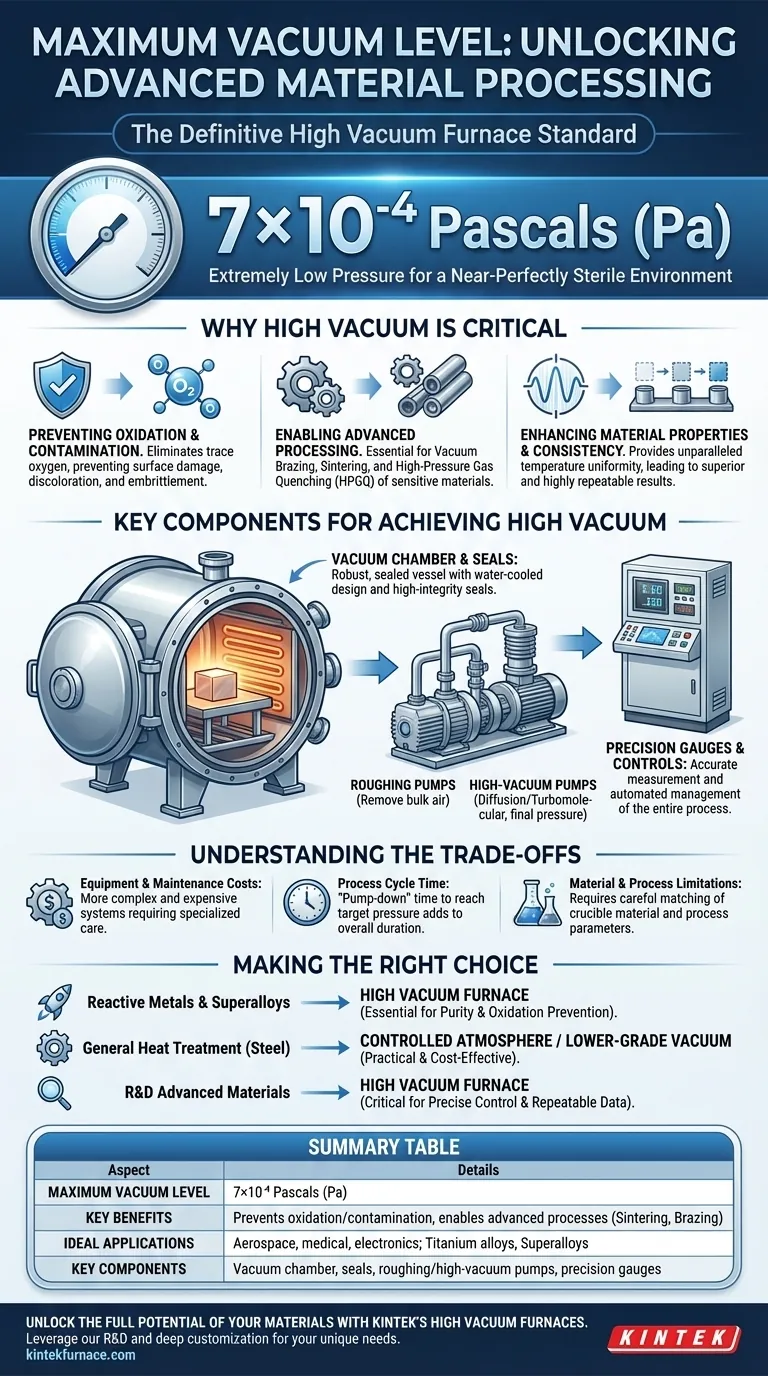

The definitive maximum vacuum level for a high vacuum furnace is typically rated at 7×10⁻⁴ Pascals (Pa). This extremely low pressure, far beyond what is found in a standard vacuum, is the key to unlocking advanced material processing by creating a near-perfectly sterile environment at very high temperatures.

A high vacuum furnace isn't just about reaching high temperatures; its primary function is to create an ultra-clean environment. The specified vacuum level is critical for preventing chemical reactions like oxidation that would otherwise compromise the integrity of sensitive materials during heating.

Why High Vacuum Is Critical in Furnace Technology

Operating a furnace under a high vacuum is fundamentally about control. At the extreme temperatures required for processes like sintering or brazing, materials become highly reactive. A high vacuum removes the atmospheric gases that would otherwise cause unwanted chemical reactions.

Preventing Oxidation and Contamination

The main purpose of the vacuum is to remove oxygen and other reactive gases. Even trace amounts of oxygen at 2000°F (1100°C) can cause significant oxidation on the surface of metals, leading to discoloration, brittleness, and compromised structural integrity.

By reducing the pressure to near-zero, the furnace virtually eliminates the risk of contamination, ensuring the material's chemical composition remains pure.

Enabling Advanced Material Processing

Certain metallurgical processes are only possible in a vacuum. A high vacuum environment is essential for:

- Vacuum Brazing: Joining two materials with a filler metal without the use of flux, resulting in a clean, strong, and uniform joint.

- Vacuum Sintering: Fusing metal powders together below their melting point to form a solid, dense part. The vacuum prevents oxidation of the fine powders.

- High-Pressure Gas Quenching (HPGQ): Rapidly cooling parts with an inert gas after the heating cycle. The process starts from a clean vacuum to ensure the quenching gas itself doesn't cause contamination.

These processes are vital for producing high-performance components for the aerospace, medical, and electronics industries using materials like titanium alloys, stainless steel, and high-temperature superalloys.

Enhancing Material Properties and Consistency

Processing in a vacuum provides unparalleled temperature uniformity, often within a few degrees across the entire part. This precision, combined with the lack of contamination, leads to superior and highly repeatable material properties.

The entire heating and cooling cycle can be computer-controlled, ensuring that every batch meets the exact same metallurgical specifications.

Key Components That Achieve High Vacuum

Achieving and maintaining a vacuum level of 7×10⁻⁴ Pa requires a sophisticated and robust system. Several key components work in concert to create this environment.

The Vacuum Chamber and Seals

The chamber is a robust, sealed vessel that contains the heating elements and the workpiece. Modern "cold wall" designs use water-cooled interlayers to keep the exterior of the furnace at a safe temperature while the interior reaches upwards of 2600°C. The integrity of the seals is paramount.

The Vacuum Pumping System

This is the heart of the furnace. It typically involves a series of pumps working in stages to remove air molecules from the chamber. Roughing pumps remove the bulk of the air first, followed by high-vacuum pumps (like diffusion or turbomolecular pumps) that take the pressure down to the final target level.

Precision Gauges and Controls

Specialized gauges are required to accurately measure such low pressures. This data is fed into an electrical control system that manages the pumps, heating elements, and gas quenching systems, allowing for precise, automated control over the entire process.

Understanding the Trade-offs

While powerful, high vacuum technology comes with inherent complexities and trade-offs that are important to understand.

Equipment and Maintenance Costs

High vacuum furnaces are significantly more complex and expensive than their atmospheric or low-vacuum counterparts. The pumps, gauges, and high-purity seals require specialized knowledge and a rigorous maintenance schedule to ensure they perform reliably.

Process Cycle Time

Achieving a high vacuum is not instantaneous. The "pump-down" time required to evacuate the chamber to the target pressure can add considerable time to the overall process cycle. Any leaks in the system can prevent the furnace from reaching the required vacuum, leading to delays.

Material and Process Limitations

While vacuum furnaces are versatile, they are not a universal solution. The choice of crucible material (graphite, alumina, etc.) and the specific process parameters must be carefully matched to the material being heated to avoid any unintended interactions, even in a vacuum.

Making the Right Choice for Your Application

Selecting the right thermal processing technology depends entirely on your material requirements and desired outcome.

- If your primary focus is processing highly reactive metals like titanium or specialty superalloys: A high vacuum furnace is essential to prevent catastrophic oxidation and ensure material purity.

- If your primary focus is general heat treatment of common steels: A controlled atmosphere furnace or a lower-grade vacuum system is often a more practical and cost-effective solution.

- If your primary focus is research and development on advanced materials: The precise control, low contamination, and process repeatability of a high vacuum furnace are critical for producing reliable data.

Ultimately, understanding the vacuum level is key to controlling the processing environment and achieving the desired material properties with absolute precision.

Summary Table:

| Aspect | Details |

|---|---|

| Maximum Vacuum Level | 7×10⁻⁴ Pascals (Pa) |

| Key Benefits | Prevents oxidation and contamination, enables advanced processes like sintering and brazing |

| Ideal Applications | Aerospace, medical, electronics industries; materials like titanium alloys and superalloys |

| Key Components | Vacuum chamber, seals, roughing and high-vacuum pumps, precision gauges |

Unlock the Full Potential of Your Materials with KINTEK's High Vacuum Furnaces

At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your unique needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to provide precise control, contamination-free environments, and superior material properties for industries like aerospace, medical, and electronics. With our strong deep customization capability, we can precisely meet your experimental requirements, ensuring optimal performance and repeatability.

Ready to enhance your lab's efficiency and achieve unparalleled results? Contact us today to discuss how our high vacuum furnaces can transform your material processing!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?