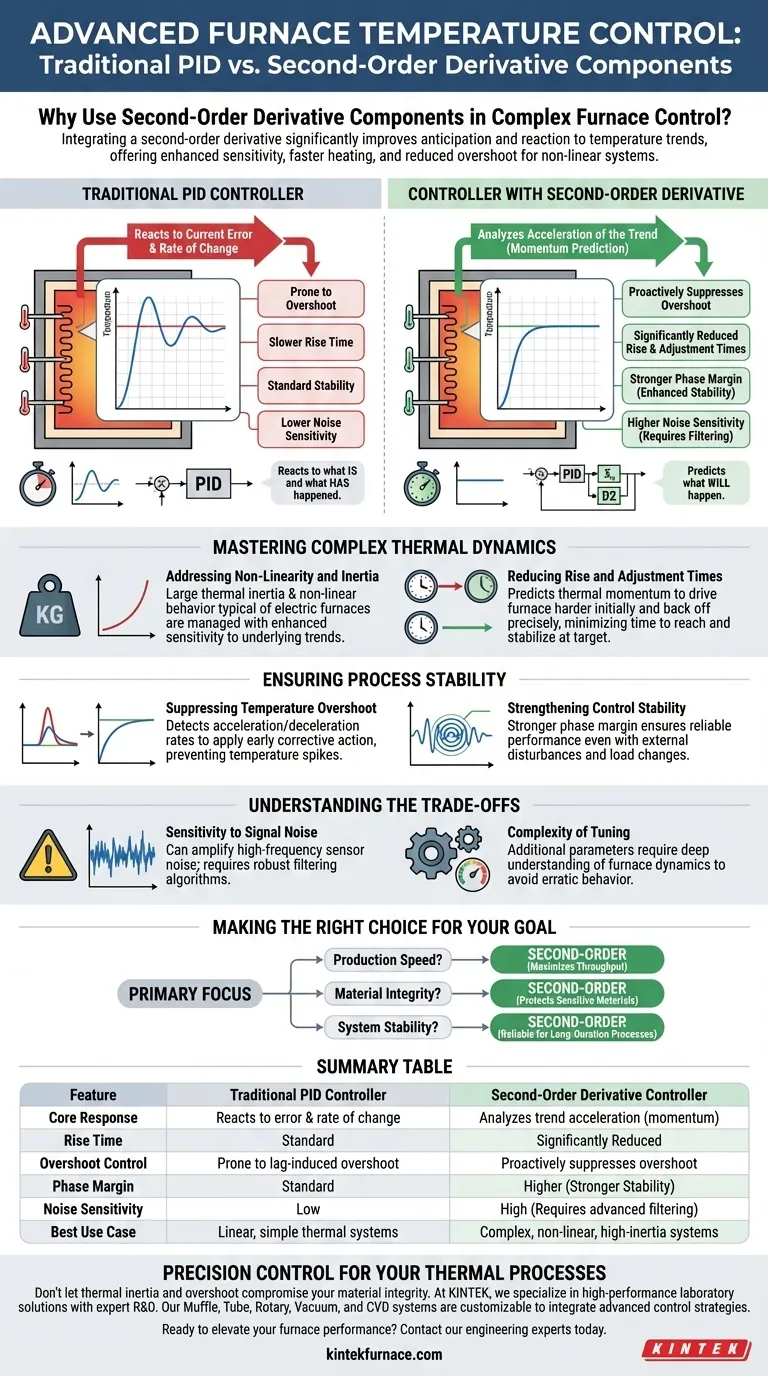

Integrating a second-order derivative component into a furnace controller significantly improves the system's ability to anticipate and react to temperature trends. Compared to a traditional PID controller, this advanced structure offers enhanced sensitivity, resulting in faster heating times and a substantial reduction in overshoot for complex, non-linear systems.

While traditional PID controllers react to current errors and rates of change, adding a second-order derivative allows the system to analyze the acceleration of the trend. This added layer of prediction effectively counteracts the massive thermal inertia typical of electric furnaces, ensuring stability where standard controllers might oscillate.

Mastering Complex Thermal Dynamics

Addressing Non-Linearity and Inertia

Electric furnace systems are characterized by large inertia, meaning they are slow to respond to energy input and slow to cool down. They are also often non-linear, behaving differently at various temperature ranges.

A controller with second-order derivative components and filters provides enhanced sensitivity to these complex behaviors. It looks beyond simple error correction to understand the underlying trend of the temperature change.

Reducing Rise and Adjustment Times

In a production environment, time is a critical resource. The primary advantage of this advanced control structure is its ability to significantly reduce rise time (how long it takes to reach the target).

It also minimizes adjustment time (how long it takes to stabilize once near the target). By predicting the thermal momentum, the controller can drive the furnace harder initially and back off precisely at the right moment.

Ensuring Process Stability

Suppressing Temperature Overshoot

One of the greatest risks in furnace control is overshoot, where the temperature exceeds the setpoint, potentially damaging the product or the heating elements.

Standard PID controllers often struggle to brake the heating process in time due to thermal lag. The second-order component effectively suppresses overshoot by detecting the rate at which the temperature rise is accelerating or decelerating, applying corrective action much earlier.

Strengthening Control Stability

For continuous production processes, consistent performance is non-negotiable. This advanced controller structure provides a stronger phase margin.

A higher phase margin directly correlates to better system stability. This ensures that even amidst external disturbances or load changes, the control loop remains tight and predictable.

Understanding the Trade-offs

Sensitivity to Signal Noise

While enhanced sensitivity is an asset for tracking temperature, it can be a liability regarding signal noise.

Second-order derivatives can amplify high-frequency noise inherent in sensor readings. Effective implementation usually requires robust filtering algorithms to ensure the controller reacts to actual temperature changes, not sensor static.

Complexity of Tuning

Moving beyond standard PID introduces additional parameters to configure.

Achieving the optimal balance between the proportional, integral, and first/second derivative terms requires a deeper understanding of the specific furnace's dynamics. Improper tuning can lead to erratic behavior rather than improved control.

Making the Right Choice for Your Goal

To determine if this advanced control strategy is right for your application, consider your specific operational constraints:

- If your primary focus is Production Speed: The second-order controller is superior for its ability to reduce rise and adjustment times, maximizing throughput.

- If your primary focus is Material Integrity: This method is ideal due to its ability to suppress overshoot, protecting sensitive materials from heat damage.

- If your primary focus is System Stability: The stronger phase margin offers the most reliable choice for long-duration, continuous processes.

By leveraging second-order derivative control, you transform your furnace from a reactive system into a predictive instrument capable of handling the most demanding thermal challenges.

Summary Table:

| Feature | Traditional PID Controller | Second-Order Derivative Controller |

|---|---|---|

| Core Response | Reacts to error and rate of change | Analyzes trend acceleration (momentum) |

| Rise Time | Standard | Significantly Reduced |

| Overshoot Control | Prone to lag-induced overshoot | Proactively suppresses overshoot |

| Phase Margin | Standard | Higher (Stronger Stability) |

| Noise Sensitivity | Low | High (Requires advanced filtering) |

| Best Use Case | Linear, simple thermal systems | Complex, non-linear, high-inertia systems |

Precision Control for Your Thermal Processes

Don't let thermal inertia and overshoot compromise your material integrity. At KINTEK, we specialize in high-performance laboratory solutions backed by expert R&D and precision manufacturing.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to integrate advanced control strategies that maximize your throughput and stability.

Ready to elevate your furnace performance? Contact our engineering experts today to discuss your unique needs and find the perfect heating solution for your lab.

Visual Guide

References

- Serdar Ekinci, Євген Зайцев. Efficient control strategy for electric furnace temperature regulation using quadratic interpolation optimization. DOI: 10.1038/s41598-024-84085-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of MoSi2 heating elements in terms of temperature capability? Unmatched High-Temp Performance

- What properties should a material have to be suitable for heating elements? Key Traits for High-Temperature Performance

- Why is a chrome-aluminum thermocouple necessary for mercury removal? Achieve 99.8% Distillation Efficiency

- What is the role of a temperature controller in the closed-loop regulation system? Master Precision Heat Control

- What are the components of a tubular heater? Discover Key Parts for Efficient Industrial Heating

- What are SIC heating elements made of and what are their key characteristics? Discover High-Temp Durability & Efficiency

- What is the purpose of K-type thermocouples and multi-channel loggers? Validating Thermal Insulation Performance

- What advantages do SiC heating elements have over traditional heating materials? Boost Efficiency and Cut Costs