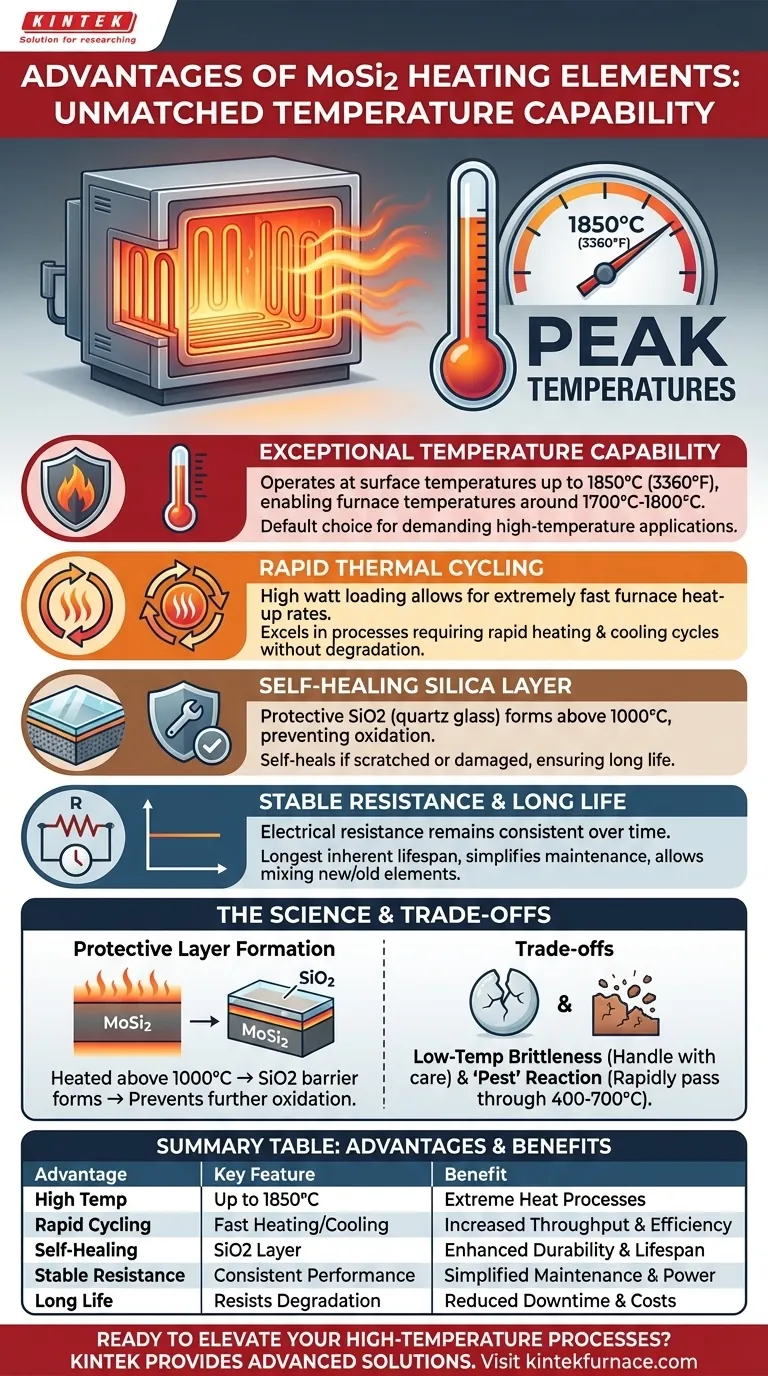

From a technical standpoint, Molybdenum Disilicide (MoSi2) heating elements are defined by their exceptional temperature capability. They can operate at surface temperatures up to 1850°C (3360°F), placing them among the highest-rated electric heating elements available and making them the default choice for the most demanding high-temperature furnace applications.

The core advantage of MoSi2 is not just its peak temperature, but its ability to reliably and rapidly cycle to those temperatures over a long service life. This performance is due to a protective, self-healing silica glass layer that forms on the element's surface, enabling consistent operation in demanding industrial and laboratory environments.

The Science Behind High-Temperature Performance

The unique properties of MoSi2 are directly tied to its material chemistry when exposed to heat and oxygen. Understanding this is key to understanding its value.

Formation of the Protective Silica Layer

When a MoSi2 element is heated above 1000°C in an oxidizing atmosphere, a thin, non-porous layer of quartz glass (SiO2) forms on its surface.

This layer is crucial. It acts as a protective barrier, preventing further oxidation of the underlying base material even at extreme temperatures. If the layer is scratched or damaged, it effectively "heals" itself as the exposed MoSi2 re-oxidizes, restoring the protective coating.

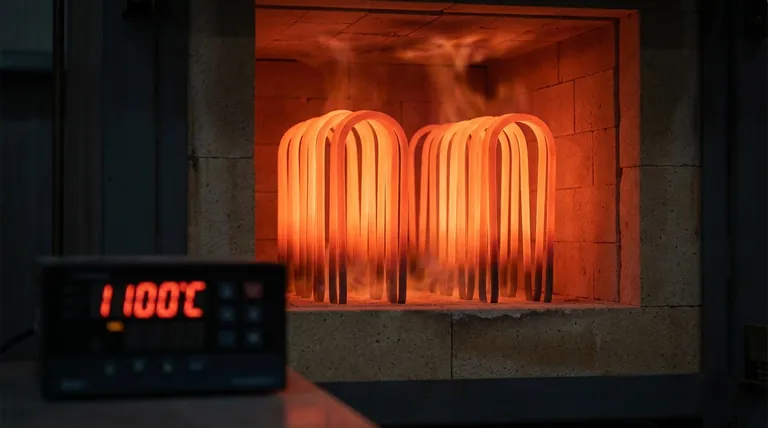

Peak Operating Temperatures

Standard MoSi2 elements are rated for continuous operation at element temperatures of 1700°C to 1800°C, allowing for furnace chamber temperatures around 1600°C to 1700°C.

Specialized grades can push this limit even further, reaching element temperatures of 1850°C or, in some cases, up to 1900°C for specific applications.

High Watt Loading and Rapid Heating

MoSi2 elements can handle very high power density, or watt loading. This means a large amount of energy can be pushed through a relatively small element.

The practical benefit is an extremely fast furnace heat-up rate. This capability is essential for processes that require rapid thermal cycling.

Key Operational Advantages

The high-temperature capability of MoSi2 is supported by several other properties that make it a practical and reliable choice.

Durability in Thermal Cycling

Unlike many ceramic elements that can be stressed or damaged by rapid temperature changes, MoSi2 elements excel in these conditions. They can be heated and cooled quickly and repeatedly without significant degradation to their mechanical or electrical properties.

Stable Electrical Resistance

The electrical resistance of MoSi2 remains relatively stable over its long service life. This is a significant operational advantage.

It means that power delivery remains consistent and predictable. It also allows for the connection of new and old elements in the same circuit without issues, simplifying maintenance.

Longevity and Ease of Maintenance

The self-healing protective layer gives MoSi2 elements the longest inherent lifespan of all metallic or ceramic heating elements.

Furthermore, individual elements can often be replaced without needing to cool the furnace down completely, which drastically reduces production downtime.

Understanding the Trade-offs

No material is perfect. The exceptional high-temperature performance of MoSi2 comes with specific handling requirements at lower temperatures.

Low-Temperature Brittleness

At room temperature, MoSi2 elements are brittle, similar to a piece of ceramic. They must be handled with great care during installation to avoid fracture. They only gain ductility at very high temperatures.

The "Pest" Reaction

If held for extended periods in a temperature range of 400-700°C, MoSi2 can undergo a form of accelerated oxidation known as "pest disintegration." This can cause the element to crumble into powder. For this reason, furnaces using MoSi2 elements should be programmed to pass through this temperature zone as quickly as possible.

Making the Right Choice for Your Application

Choosing a heating element depends entirely on your process requirements. MoSi2 offers unmatched performance at the top end of the temperature spectrum.

- If your primary focus is reaching the highest possible process temperatures (1600°C+): MoSi2 elements are the industry standard due to their unmatched temperature ceiling and stability.

- If your primary focus is rapid process cycling and high throughput: The ability of MoSi2 to handle fast thermal changes without degradation makes it superior to most other element types.

- If your primary focus is operational uptime and low maintenance: The long service life and ability to replace individual hot elements significantly reduce furnace downtime.

By understanding both its unparalleled high-temperature strengths and its specific handling requirements, you can effectively leverage MoSi2 technology to achieve your most demanding thermal processing goals.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| High Temperature Capability | Operates up to 1850°C | Ideal for extreme heat processes |

| Rapid Thermal Cycling | Handles fast heating/cooling | Increases throughput and efficiency |

| Self-Healing Silica Layer | Forms protective SiO2 coating | Enhances durability and lifespan |

| Stable Electrical Resistance | Consistent performance over time | Simplifies maintenance and power control |

| Long Service Life | Resists degradation in cycling | Reduces downtime and replacement costs |

Ready to elevate your high-temperature processes with reliable MoSi2 heating elements? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, boosting efficiency and performance. Contact us today to discuss how our tailored furnace solutions can benefit your laboratory!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C