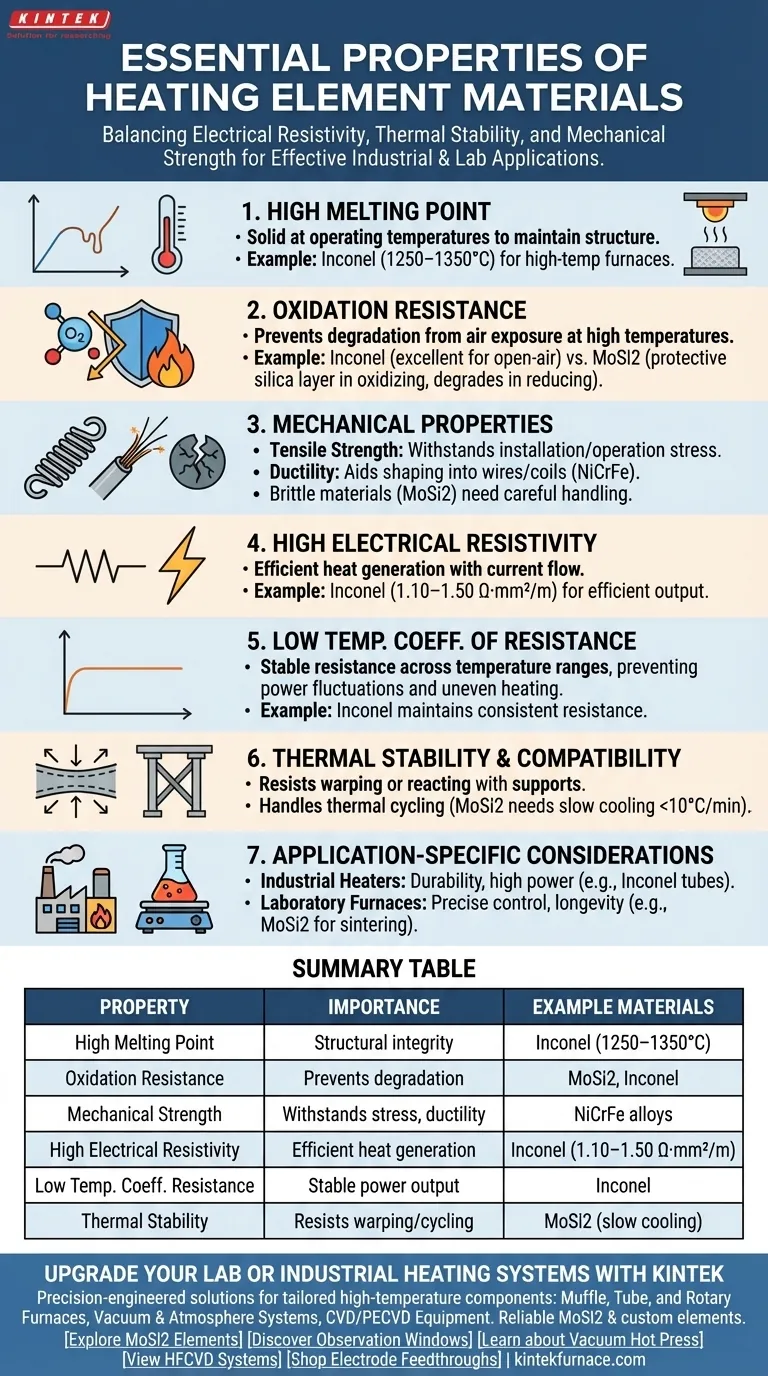

Heating elements are critical components in various industrial and laboratory applications, requiring specific material properties to function effectively. The ideal material should balance high electrical resistivity with thermal stability, mechanical strength, and resistance to oxidation. Key considerations include the ability to withstand repeated thermal cycling, maintain structural integrity at high temperatures, and efficiently convert electrical energy to heat. Materials like MoSi2 and Inconel demonstrate these properties but come with unique handling requirements and environmental sensitivities. Understanding these characteristics helps in selecting the right heating element for specific applications, whether in furnaces, industrial heaters, or laboratory equipment.

Key Points Explained:

-

High Melting Point

- The material must remain solid at operating temperatures to maintain structural integrity. For example, Inconel melts at 1250–1350°C, making it suitable for high-temperature furnaces.

- Materials with low melting points would deform or fail under typical heating conditions.

-

Oxidation Resistance

- Exposure to air at high temperatures can cause oxidation, degrading the element. MoSi2 forms a protective silica layer in oxidizing environments but deteriorates in reducing atmospheres.

- Inconel's excellent oxidation resistance makes it ideal for open-air heating applications.

-

Mechanical Properties

- Tensile Strength: Ensures the element can withstand mechanical stress during installation and operation.

- Ductility: Allows the material to be drawn into wires or shaped into coils, as seen with NiCrFe alloys.

- Brittle materials like MoSi2 require careful handling to avoid breakage.

-

Electrical Resistivity

- High resistivity (e.g., Inconel's 1.10–1.50 Ω·mm²/m) ensures efficient heat generation when current passes through.

- Low-resistivity materials would require excessive current to produce the same heat output.

-

Low Temperature Coefficient of Resistance

- Stable resistance across temperature ranges prevents power fluctuations. Inconel maintains consistent resistance even at elevated temperatures.

- Materials with high coefficients could lead to uneven heating or electrical system overloads.

-

Thermal Stability and Compatibility

- Materials must resist warping or reacting with supports (e.g., alumina trays for MoSi2 elements).

- Rapid thermal cycling can damage brittle elements; MoSi2 requires heating/cooling rates below 10°C/minute.

-

Application-Specific Considerations

- Industrial Heaters: Need durability and high power output (e.g., Inconel in electric heating tubes).

- Laboratory Furnaces: Require precise temperature control and longevity (e.g., MoSi2 for sintering).

By evaluating these properties, purchasers can select heating elements tailored to their operational needs, whether prioritizing longevity, temperature range, or environmental resistance.

Summary Table:

| Property | Importance | Example Materials |

|---|---|---|

| High Melting Point | Ensures structural integrity at high temperatures | Inconel (1250–1350°C) |

| Oxidation Resistance | Prevents degradation in air; critical for longevity | MoSi2, Inconel |

| Mechanical Strength | Withstands stress during installation/operation; ductility aids shaping | NiCrFe alloys |

| High Electrical Resistivity | Efficient heat generation with minimal current | Inconel (1.10–1.50 Ω·mm²/m) |

| Low Temp. Coeff. of Resistance | Stable power output across temperatures | Inconel |

| Thermal Stability | Resists warping/reacting with supports; handles thermal cycling | MoSi2 (slow cooling) |

Upgrade your lab or industrial heating systems with precision-engineered solutions from KINTEK. Our expertise in R&D and in-house manufacturing ensures tailored high-temperature furnace components, including Muffle, Tube, and Rotary Furnaces, Vacuum & Atmosphere Systems, and CVD/PECVD Equipment. Whether you need robust heating elements like MoSi2 or custom configurations, we deliver reliability and performance. Contact us today to discuss your specific requirements!

Products You Might Be Looking For:

Explore high-performance MoSi2 heating elements

Discover vacuum-compatible observation windows for furnaces

Learn about precision vacuum hot press furnaces

View advanced HFCVD systems for diamond coatings

Shop ultra-vacuum electrode feedthroughs

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism