The primary advantages of silicon carbide (SiC) heating elements in dental furnaces are their superior high-temperature performance, exceptional chemical stability, and long-term durability. These characteristics make them the industry standard for demanding processes like the sintering of high-strength zirconia, where material purity and consistent thermal processing are critical to the final restoration's success.

The decision to use silicon carbide heating elements is less about a single feature and more about a strategic investment in reliability. For dental labs focused on high-quality zirconia restorations, SiC provides the thermal stability and chemical purity necessary to achieve consistent results, minimize costly remakes, and reduce long-term operational costs.

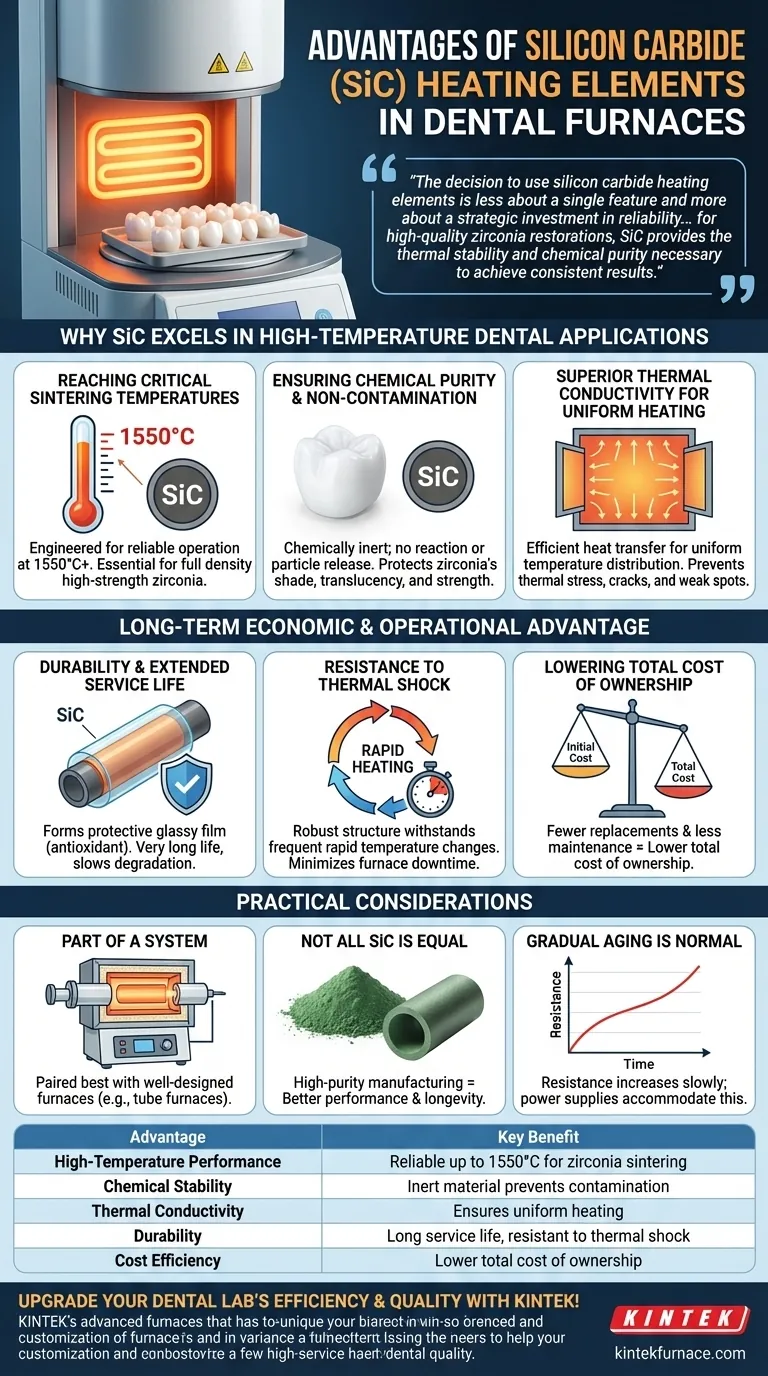

Why SiC Excels in High-Temperature Dental Applications

The core function of a dental furnace is to apply heat precisely and cleanly. Silicon carbide elements are uniquely suited for the most demanding tasks in a modern dental lab for several key reasons.

Reaching Critical Sintering Temperatures

Most high-strength zirconia materials require sintering temperatures up to, and sometimes exceeding, 1550°C to achieve full density and optimal mechanical properties. SiC elements are engineered to operate comfortably and reliably at these temperatures, providing the necessary thermal energy without risk of failure.

Ensuring Chemical Purity and Non-Contamination

Zirconia is highly sensitive to chemical contamination during sintering, which can affect its final shade, translucency, and strength. SiC is chemically inert and does not react with or release particles that could contaminate the zirconia restorations. This chemical compatibility is arguably its most critical advantage in a dental setting.

Superior Thermal Conductivity for Uniform Heating

SiC possesses high thermal conductivity, meaning it transfers heat efficiently and evenly throughout the furnace chamber. This leads to uniform temperature distribution, which is essential for predictable shrinkage and preventing thermal stress that can cause cracks or weak spots in the final restorations.

The Long-Term Economic and Operational Advantage

While performance is paramount, lab owners and managers must also consider operational efficiency and total cost of ownership. SiC elements provide significant long-term value that goes beyond their initial purchase price.

Durability and Extended Service Life

High-quality SiC elements form a protective glassy film (silicon dioxide) on their surface during operation. This self-healing layer acts as an antioxidant, dramatically slowing degradation and giving the elements a very long service life even with frequent, rapid heating and cooling cycles.

Resistance to Thermal Shock

Dental labs often run multiple furnace cycles per day. SiC's robust structure gives it excellent resistance to thermal shock, meaning it can withstand repeated heating and cooling without cracking or failing prematurely. This resilience is vital for maintaining productivity and minimizing furnace downtime.

Lowering the Total Cost of Ownership

Although other heating element types may have a lower initial cost, the durability of SiC means fewer replacements, less maintenance, and significantly less downtime. Over the lifespan of the furnace, this reliability often results in a lower total cost of ownership and higher lab throughput.

Understanding the Practical Considerations

While SiC offers clear benefits, it's important to view it as part of a complete system. Its performance is influenced by the furnace design and proper use.

The Element is Part of a System

The most common furnace design in dental labs is the tube furnace, which is simple, efficient, and allows for controlled heating zones. The effectiveness of a SiC element is maximized when it is paired with a well-designed furnace that has quality insulation and precise temperature controls.

Not All SiC is Created Equal

The performance and longevity of a SiC element are directly tied to its manufacturing quality. Elements made from high-purity green silicon carbide powder result in a denser, more uniform component. Sourcing elements from reputable manufacturers ensures you get the antioxidant properties and durability you expect.

Gradual Aging is Normal

Over hundreds or thousands of hours of use, all SiC elements will slowly increase in electrical resistance. This is a normal aging process. A well-designed furnace power supply is built to accommodate this change, but it is a factor to be aware of for long-term maintenance planning.

Making the Right Choice for Your Lab

Selecting the right heating element is a technical decision that directly impacts your lab's quality, efficiency, and profitability.

- If your primary focus is high-strength zirconia restorations: SiC is the definitive choice for its ability to reach high temperatures cleanly without compromising the material's purity or aesthetics.

- If your primary focus is operational efficiency and uptime: The exceptional durability and long service life of SiC elements minimize furnace downtime, replacement labor, and associated costs.

- If your primary focus is consistent, repeatable results: The high thermal conductivity of SiC promotes uniform heating, which is crucial for achieving predictable sintering and reducing the frequency of costly remakes.

Ultimately, choosing silicon carbide heating elements is a strategic decision to invest in the quality and reliability of your lab's most critical thermal processes.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High-Temperature Performance | Reliable operation up to 1550°C for zirconia sintering |

| Chemical Stability | Inert material prevents contamination of restorations |

| Thermal Conductivity | Ensures uniform heating for consistent results |

| Durability | Long service life with resistance to thermal shock |

| Cost Efficiency | Lower total cost of ownership due to reduced maintenance |

Upgrade your dental lab's efficiency and quality with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, helping you achieve consistent zirconia sintering results, minimize downtime, and reduce operational costs. Contact us today to discuss how our tailored solutions can benefit your lab!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat