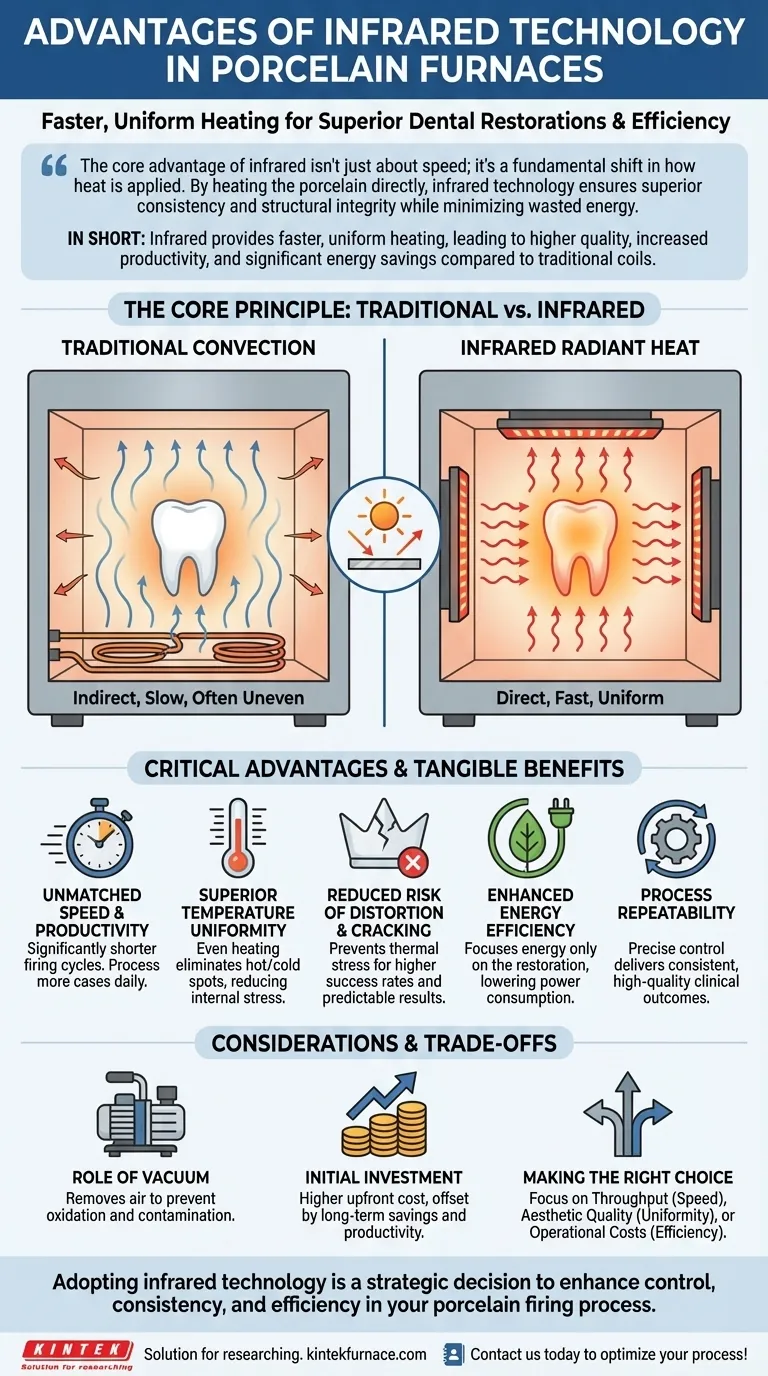

In short, infrared technology provides faster, more uniform heating for porcelain furnaces. This leads to higher quality dental restorations, increased productivity for the lab, and significant energy savings compared to furnaces that rely on traditional heating coils.

The core advantage of infrared isn't just about speed; it's a fundamental shift in how heat is applied. By heating the porcelain directly, infrared technology ensures superior consistency and structural integrity while minimizing wasted energy.

The Core Principle: How Infrared Heating Differs

To understand the benefits of infrared (IR), you must first understand how it differs from the conventional heating methods used in older furnaces.

Traditional Convection vs. Radiant Heat

Traditional furnaces use resistance coils that heat the air inside the chamber. This hot air then slowly transfers its energy to the porcelain restoration through convection. This process is indirect, slow, and often uneven.

Infrared technology works on the principle of radiant heat. It emits electromagnetic waves that travel directly to the porcelain, bypassing the air. The porcelain absorbs this energy and heats up from within, much like how the sun warms a surface on a cool day.

Translating Technology into Tangible Benefits

This fundamental difference in heat delivery creates several critical advantages that impact both the quality of your work and the efficiency of your lab.

Unmatched Speed and Productivity

Because IR energy is transferred directly to the restoration, firing cycles are significantly shorter. Less time is wasted heating the air and the entire furnace chamber, allowing you to process more cases in a single day and boost overall productivity.

Superior Temperature Uniformity

Radiant heat ensures the entire surface of the porcelain restoration is heated evenly and simultaneously. This eliminates the hot and cold spots common with convection heating, which can create internal stress within the material.

Reduced Risk of Distortion and Cracking

By preventing uneven heating and the resulting thermal stress, IR technology drastically reduces the risk of distortion, fractures, or porcelain cracking. This leads to a higher rate of successful restorations, predictable results, and fewer costly remakes.

Enhanced Energy Efficiency

Conventional furnaces waste a tremendous amount of energy heating the air and thick refractory walls of the chamber. Infrared technology focuses energy only where it's needed—on the restoration itself—leading to lower power consumption and reduced operational costs over time.

Understanding the Trade-offs and Considerations

While the advantages are clear, a complete picture requires acknowledging the practical considerations of adopting this technology.

The Role of Vacuum

Many modern infrared furnaces integrate vacuum technology. A vacuum removes air and impurities from the firing chamber, preventing oxidation and contamination. This combination of precise IR heating in a pure vacuum environment provides unparalleled control for achieving the highest quality results.

Initial Investment

Furnaces equipped with advanced infrared technology typically have a higher initial purchase price than basic conventional models. This cost, however, is often offset over the long term through energy savings, increased productivity, and fewer material failures.

Process Repeatability

The precise nature of IR heating, often paired with automated temperature and time controls, delivers exceptional process repeatability. You can be confident that the firing program will yield the same high-quality result every time, which is critical for consistent clinical outcomes.

Making the Right Choice for Your Goal

Your specific priorities will determine how much you benefit from infrared technology.

- If your primary focus is maximizing throughput: Infrared's dramatically faster firing cycles will be the most significant advantage, allowing your lab to increase its daily capacity.

- If your primary focus is achieving the highest aesthetic quality: The superior temperature uniformity is key, as it ensures the structural integrity and predictable shade of your restorations by minimizing thermal stress.

- If your primary focus is lowering long-term operational costs: The significant energy efficiency of direct radiant heating will provide a clear and measurable return on your investment.

Ultimately, adopting infrared technology is a strategic decision to enhance control, consistency, and efficiency in your porcelain firing process.

Summary Table:

| Advantage | Description |

|---|---|

| Faster Heating | Significantly shorter firing cycles for increased productivity. |

| Superior Uniformity | Even heating reduces hot and cold spots, preventing stress. |

| Reduced Distortion | Minimizes risk of cracking and fractures for higher success rates. |

| Energy Efficiency | Direct heating lowers power consumption and operational costs. |

| Process Repeatability | Consistent results with automated controls for reliable outcomes. |

Ready to elevate your dental lab with advanced infrared furnace solutions? KINTEK specializes in high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique needs—ensuring precise temperature control, energy savings, and enhanced productivity. Contact us today to discuss how we can optimize your porcelain firing process!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations