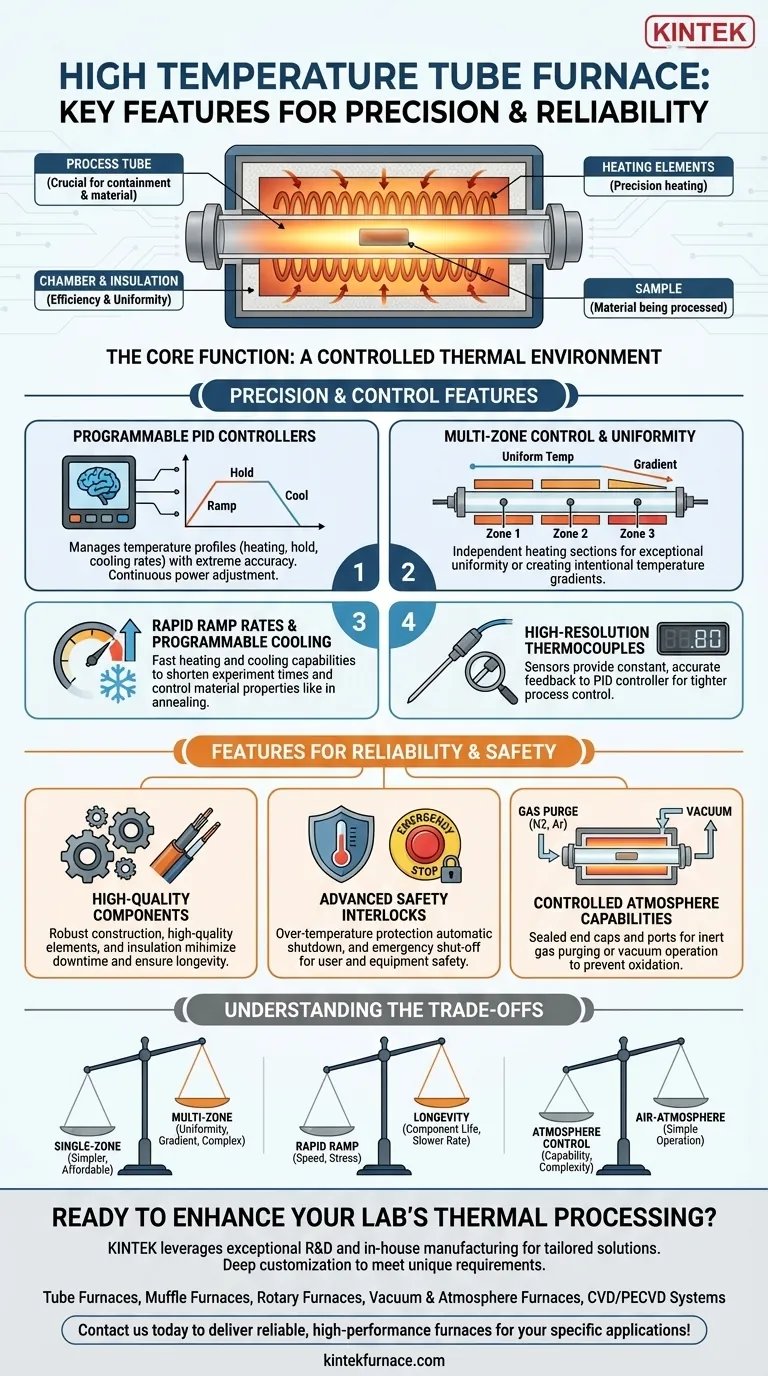

The key features of a high temperature tube furnace are designed to deliver precise thermal processing, operational reliability, and user safety. Core capabilities include a fully programmable control system for managing temperature profiles, multi-zone heating for exceptional uniformity, rapid heating and cooling rates, and advanced safety interlocks like over-temperature protection and controlled atmosphere management.

A modern tube furnace is more than just a heating device; it is a precision instrument. Its true value is defined by its ability to create and repeatedly maintain a highly specific, uniform, and safe thermal environment, which is the foundation of successful material processing and synthesis.

The Core Function: A Controlled Thermal Environment

A high temperature tube furnace is fundamentally an electric heater designed for processing samples within a contained, cylindrical space. Its purpose is to apply a precise thermal cycle to a material under tightly controlled conditions.

How a Tube Furnace Works

The furnace consists of a ceramic or metallic process tube placed inside a chamber. Heating elements, typically coils of wire, are wrapped around this chamber. When electricity passes through these elements, they heat up, transferring thermal energy through the chamber walls to the process tube and the sample inside.

The Importance of the Process Tube

The process tube itself is a critical component. The material and dimensions of the tube are chosen based on the maximum required temperature and the chemical reactivity of the sample and any process gases being used.

Key Features for Precision and Control

The quality of a tube furnace is determined by its ability to precisely control the heating and cooling process. Several features work in concert to achieve this.

Programmable PID Controllers

The "brain" of the furnace is its PID (Proportional-Integral-Derivative) controller. This system allows you to program a specific temperature profile—including heating rates, hold times, and cooling rates—and it continuously adjusts power to the heating elements to follow that profile with extreme accuracy.

Uniform Temperature and Multi-Zone Control

For many applications, it is critical that the sample is heated evenly along its entire length. Furnaces achieve this through optimized heating element design. More advanced models feature multi-zone control, with several independent heating sections and thermocouples along the tube, to guarantee temperature uniformity or even create intentional temperature gradients.

Rapid Ramp Rates and Programmable Cooling

The speed at which the furnace can heat up (ramp rate) and cool down is a significant feature. Rapid rates can shorten experiment times, while programmable cooling is essential for processes like annealing, where the cooling profile directly impacts the final material properties.

High-Resolution Thermocouples

Thermocouples are the "nerves" of the system, acting as temperature sensors that provide constant feedback to the PID controller. High-resolution thermocouples provide more accurate and stable temperature readings, enabling tighter control over the process.

Features for Reliability and Safety

A furnace must not only be precise but also robust and safe to operate, especially at the high temperatures it can achieve.

High-Quality Components

Reliability starts with construction. The use of high-quality heating elements, insulation, and electronics minimizes downtime and ensures that experiments are not ruined by equipment failure. A low-maintenance design reduces the total cost of ownership.

Over-Temperature Protection

This is a critical safety interlock. A separate monitoring circuit will automatically shut down the furnace if it exceeds a set temperature limit, protecting the sample, the equipment, and the laboratory from a thermal runaway event.

Controlled Atmosphere Capabilities

Many materials must be heated in the absence of oxygen to prevent oxidation. Furnaces are designed with sealed end caps and gas ports to allow for gas purging (e.g., with Nitrogen or Argon) or for operating under a vacuum.

Emergency Shut-Off

A clearly marked emergency stop button provides a simple, manual way to cut all power to the furnace in case of an unforeseen problem.

Understanding the Trade-offs

Choosing a furnace involves balancing capability against complexity and cost. Understanding the inherent trade-offs is key to making an informed decision.

Single-Zone vs. Multi-Zone

A single-zone furnace is simpler, more affordable, and perfectly adequate for many applications. However, if you require exceptional temperature uniformity over a long sample or need to create a temperature gradient, the added cost and complexity of a multi-zone furnace are necessary.

Ramp Rate vs. Furnace Longevity

Extremely fast ramp rates place significant thermal stress on the heating elements and insulation. While convenient, frequent use of maximum ramp rates can shorten the lifespan of these components.

Atmosphere Control Complexity

Adding vacuum pumps, gas lines, and mass flow controllers adds significant capability but also increases initial cost, maintenance requirements, and operational complexity. A simple air-atmosphere furnace is far easier to operate.

Making the Right Choice for Your Application

Select a furnace based on the specific demands of your work. The most expensive model is not always the best choice if its advanced features are not required.

- If your primary focus is material synthesis or crystal growth: Prioritize a furnace with multi-zone control and programmable cooling for creating precise thermal profiles.

- If your primary focus is routine annealing or drying: A reliable single-zone furnace with good temperature uniformity is likely sufficient and more cost-effective.

- If you are working with reactive or sensitive materials: Advanced safety features and robust atmosphere control (gas purge/vacuum capabilities) are non-negotiable.

Ultimately, the right tube furnace is the one whose features directly support the specific thermal processing requirements of your work.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Programmable PID Control | Allows precise temperature profile management with heating, hold, and cooling rates. | Ensures accurate and repeatable thermal cycles for consistent results. |

| Multi-Zone Heating | Independent heating sections for exceptional temperature uniformity or gradients. | Ideal for long samples and applications requiring specific thermal environments. |

| Rapid Ramp Rates | Fast heating and programmable cooling capabilities. | Reduces experiment time and enables controlled processes like annealing. |

| Advanced Safety Interlocks | Includes over-temperature protection, emergency shut-off, and atmosphere control. | Protects equipment, samples, and users from hazards, ensuring safe operation. |

| Controlled Atmosphere | Supports gas purging (e.g., Nitrogen, Argon) or vacuum operation to prevent oxidation. | Essential for processing reactive or sensitive materials in inert environments. |

Ready to enhance your lab's thermal processing with a high temperature tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can deliver reliable, high-performance furnaces for your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety