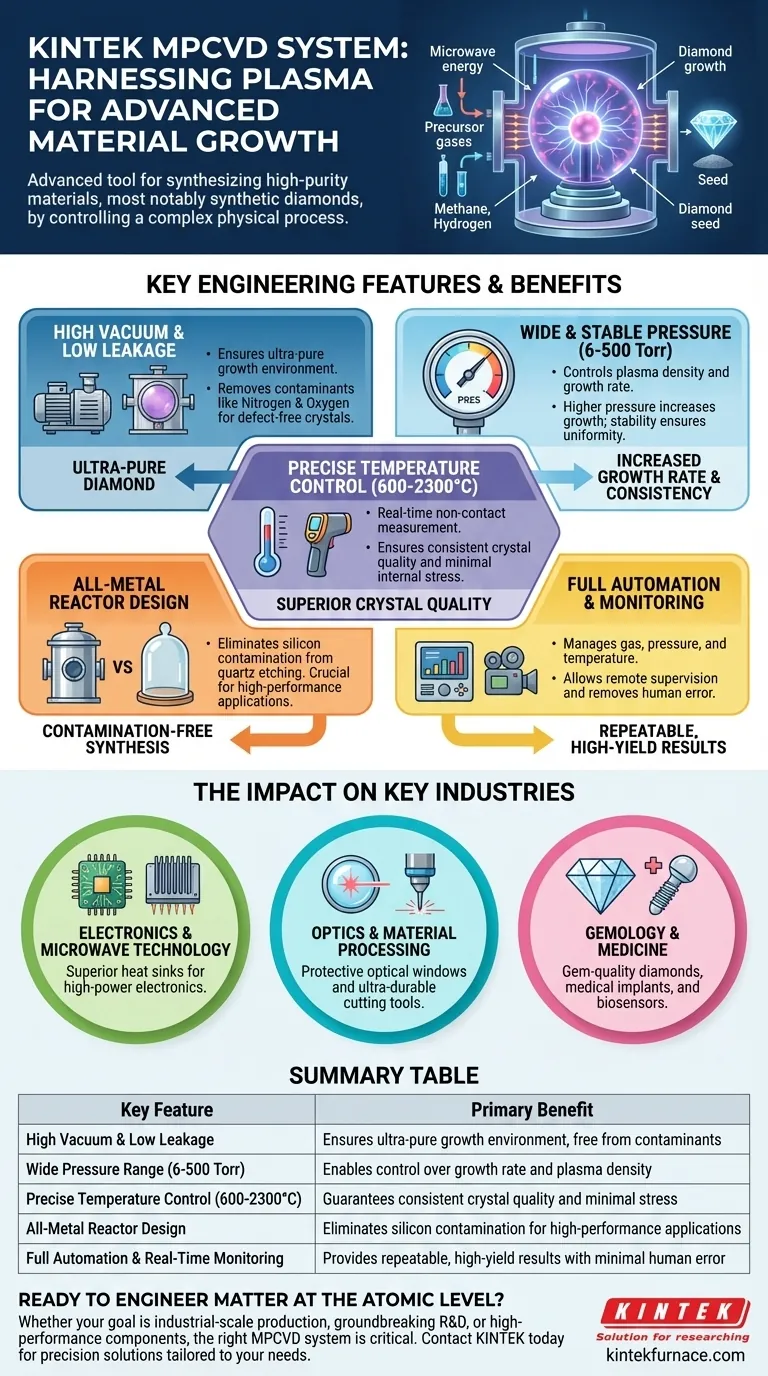

At its core, a Microwave Plasma Chemical Vapor Deposition (MPCVD) system is an advanced tool for synthesizing high-purity materials, most notably synthetic diamonds. Its key features include a high-vacuum, all-metal reaction chamber, a wide operating pressure range (6-500 Torr), and highly stable plasma generation. These are complemented by precise temperature measurement (600-2300°C), full automation, and real-time video monitoring to ensure repeatable, high-quality results.

The true value of an MPCVD system lies not in its individual components, but in their synergy. Together, they create a meticulously controlled environment that transforms simple gases into some of the world's most advanced materials with exceptional purity and consistency.

The Core Principle: Harnessing Plasma for Material Growth

To understand the benefits of an MPCVD system, you must first understand its fundamental purpose. It is designed to control a complex physical process with high fidelity.

What is MPCVD?

The process involves using microwave energy to excite precursor gases (like methane and hydrogen) within a vacuum chamber. This energy creates a plasma—a superheated ball of ionized gas.

Within this plasma, the gas molecules break apart into reactive chemical species. These species then deposit onto a substrate (often a small diamond seed), arranging themselves atom-by-atom to form a larger, synthetic diamond crystal or film.

Key Materials Synthesized

While primarily known for diamond, the system's precision makes it versatile. It is engineered for the deposition of polycrystalline, monocrystalline, and nanocrystalline diamond films. It can also be adapted to produce other advanced carbon allotropes like carbon nanotubes and nanowires.

Deconstructing the Key Engineering Features

Each feature of an MPCVD system is purpose-built to solve a specific challenge in material synthesis. The design choices directly impact the quality, purity, and growth rate of the final product.

High Vacuum & Low Leakage

A high-vacuum environment is the first step to ensuring purity. By evacuating the chamber, you remove atmospheric contaminants like nitrogen and oxygen that could otherwise be incorporated as defects into the diamond's crystal lattice. The low leakage rate ensures this pristine environment is maintained throughout the entire growth cycle, which can last for hundreds of hours.

Wide & Stable Operating Pressure (6-500 Torr)

Pressure directly influences the density of the plasma and the concentration of reactive species. The ability to operate across a wide pressure range gives scientists and engineers a critical lever to control the process.

Higher pressures can significantly increase the growth rate of the diamond, while the system's ability to maintain a stable plasma at any setting ensures the growth is uniform and consistent.

Precise Temperature Control (600-2300°C)

Temperature is one of the most critical parameters in diamond growth. Even small fluctuations can impact the quality of the crystal. MPCVD systems use non-contact two-wave pyrometers for high-precision temperature measurement directly on the growing sample's surface. This allows the system to make real-time adjustments, ensuring the diamond forms with the desired structure and minimal internal stress.

All-Metal Reactor Design

Older systems often used quartz bell jars as reaction chambers. However, the intense plasma can etch the quartz, releasing silicon impurities that contaminate the diamond. Modern MPCVD systems use an all-metal reactor design to eliminate this source of contamination, which is crucial for producing the ultra-pure diamond required for high-performance electronic and optical applications.

Full Automation and Monitoring

Synthesizing a large, high-quality diamond is a marathon, not a sprint. The growth process is long and requires unwavering stability. Full automation removes the risk of human error, managing gas flow, pressure, and temperature according to a precise recipe. Integrated video monitoring allows for remote supervision, ensuring the process runs smoothly without interruption.

The Impact on Key Industries

The combination of these features enables the use of MPCVD-grown materials in some of today's most demanding fields. The system's precision translates directly to material performance.

Electronics and Microwave Technology

Diamond's ability to dissipate heat is unparalleled. The high purity achieved in MPCVD systems allows for the creation of diamond films that act as superior heat sinks for high-power electronics, preventing them from overheating.

Optics and Material Processing

Diamond is both transparent across a wide spectrum and incredibly hard. These properties make it an ideal material for protective optical windows in harsh environments (e.g., for lasers or sensors) and for creating ultra-durable cutting tools.

Gemology and Medicine

The ability to grow large, flawless, single-crystal diamonds has obvious applications in the gem industry. Furthermore, diamond's inertness and biocompatibility make it a promising material for medical implants and biosensors.

How This Applies to Your Goal

The right features to focus on depend entirely on your intended application.

- If your primary focus is industrial-scale production of gem-quality diamonds: Prioritize the wide pressure range for maximizing growth rate and the full automation for ensuring consistent, high-yield production runs.

- If your primary focus is research and development of novel materials: The precise temperature control and clean, all-metal reactor are paramount for experimental integrity and achieving the material purity needed for scientific discovery.

- If your primary focus is creating high-performance electronic or optical components: The high-vacuum system and low-leakage design are non-negotiable, as even trace impurities can degrade the thermal and optical performance of the final device.

Ultimately, the MPCVD system provides an unparalleled level of control, enabling you to engineer matter at the atomic level.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| High Vacuum & Low Leakage | Ensures ultra-pure growth environment, free from contaminants |

| Wide Pressure Range (6-500 Torr) | Enables control over growth rate and plasma density |

| Precise Temperature Control (600-2300°C) | Guarantees consistent crystal quality and minimal stress |

| All-Metal Reactor Design | Eliminates silicon contamination for high-performance applications |

| Full Automation & Real-Time Monitoring | Provides repeatable, high-yield results with minimal human error |

Ready to Engineer Matter at the Atomic Level?

Whether your goal is industrial-scale production of gem-quality diamonds, groundbreaking R&D on novel materials, or creating high-performance electronic components, the right MPCVD system is critical.

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced high-temperature furnace solutions tailored to your unique needs. Our deep customization expertise ensures your MPCVD system—whether a Muffle, Tube, Rotary, Vacuum & Atmosphere Furnace, or CVD/PECVD System—is perfectly aligned with your experimental requirements.

Contact us today to discuss how our precision engineering can accelerate your material synthesis and deliver the purity, consistency, and control your projects demand.

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition