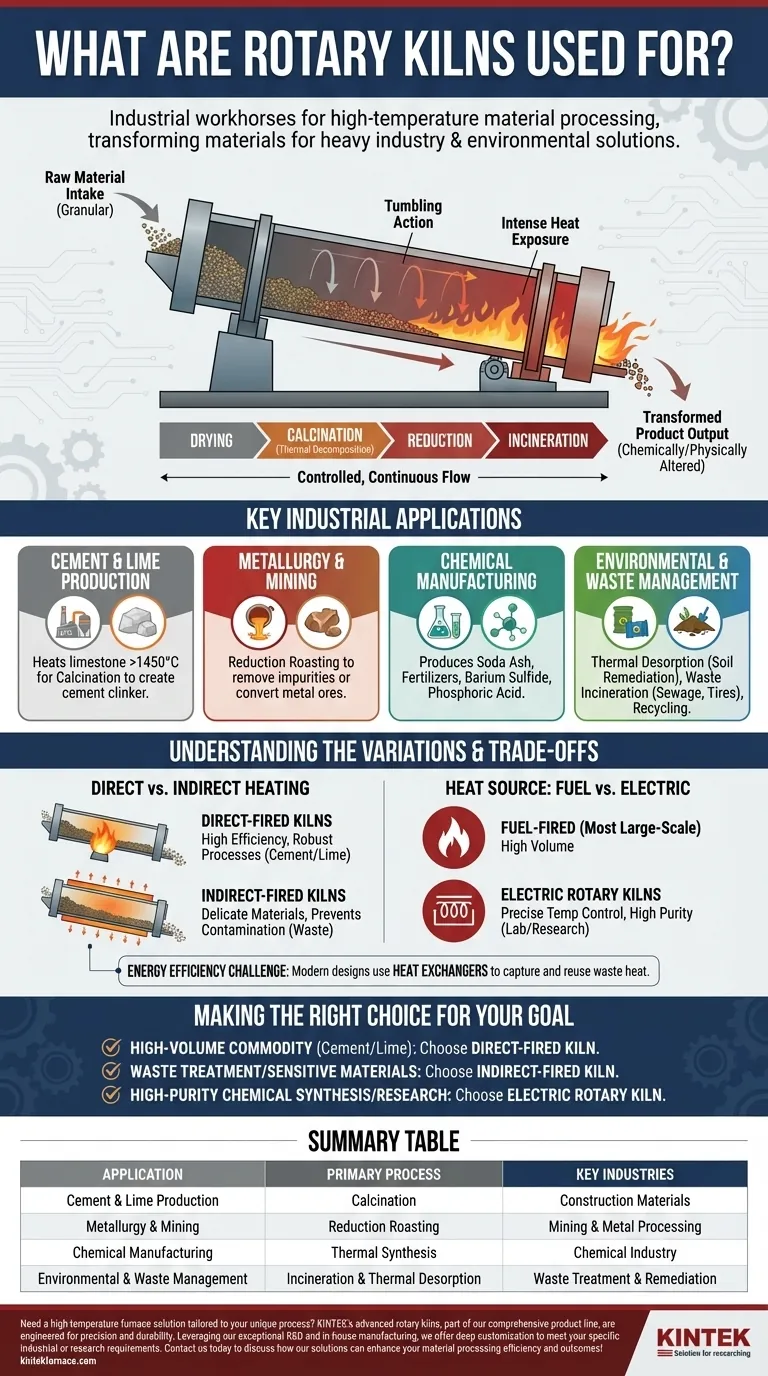

At their core, rotary kilns are industrial workhorses designed for high-temperature material processing. They are primarily used in industries like cement production, lime calcination, and metallurgy for processes that require intense heat to induce a chemical reaction or physical change in solid materials. Their applications also extend to environmental solutions, such as incinerating waste and remediating contaminated soil.

A rotary kiln is essentially a massive, rotating, and slightly inclined oven. Its core function is to use extreme heat and controlled tumbling to transform raw, granular materials into chemically or physically altered products, making it a cornerstone of heavy industry and environmental processing.

The Core Function: Transforming Materials with Heat and Motion

A rotary kiln is a long, cylindrical furnace that rotates slowly on its axis. The entire cylinder is mounted at a slight angle, which allows gravity to guide material from the upper feed end down to the discharge end.

The Process in Action

As the kiln rotates, the raw material inside tumbles and mixes continuously. This tumbling action ensures that every particle is uniformly exposed to the intense heat generated by a flame or electrical source inside the kiln.

Why This Design is Effective

This combination of rotation, inclination, and high temperature is what makes the kiln so versatile. It facilitates a range of thermal processes, including drying, calcination (thermal decomposition), reduction, and incineration, in a controlled, continuous flow.

Key Industrial Applications

The unique design of the rotary kiln makes it indispensable across several major industries for transforming bulk materials.

Cement and Lime Production

This is the most well-known application. Raw materials, primarily limestone, are heated to over 1450°C (2640°F) to undergo calcination. This process drives off carbon dioxide and creates calcium oxide, the primary component of cement clinker.

Metallurgy and Mining

In metallurgy, rotary kilns are used for processes like reduction roasting. This involves heating metal ores to remove impurities or convert them into a more desirable metallic form before smelting.

Chemical Manufacturing

The chemical industry uses rotary kilns to produce a variety of products. For example, they are used to create soda ash, calcined phosphate fertilizers, and barium sulfide. A notable innovation uses kilns to produce phosphoric acid with lower energy consumption and without the need for sulfuric acid.

Environmental and Waste Management

Rotary kilns are critical tools for environmental remediation. They are used for the thermal desorption of contaminants from soil, the safe incineration of hazardous and non-hazardous waste (like sewage sludge or scrap tires), and for recycling processes.

Understanding the Variations and Trade-offs

Not all rotary kilns are the same. The design is adapted based on the specific material being processed and the desired outcome, leading to important trade-offs.

Direct vs. Indirect Heating

Direct-fired kilns are highly efficient because the flame comes into direct contact with the material. This is ideal for robust processes like cement and lime production where potential contamination from combustion byproducts is not a concern.

Indirect-fired kilns heat the material through the shell of the rotating cylinder, keeping it separate from the flame. This is essential when processing delicate materials, preventing product contamination, or treating certain types of waste.

Heat Source: Fuel vs. Electric

While most large-scale kilns are fuel-fired, electric rotary kilns offer exceptional temperature control. They are often used for high-purity applications, chemical molecular sieve roasting, or in laboratory and pilot-plant settings where precision is paramount.

The Challenge of Energy Efficiency

Rotary kilns are inherently energy-intensive. Modern designs often incorporate heat exchangers that capture waste heat from the exhaust gas and reuse it to preheat the raw material, significantly improving overall thermal efficiency.

Making the Right Choice for Your Goal

The optimal rotary kiln process is determined entirely by the material you are processing and your end goal.

- If your primary focus is high-volume commodity production (cement, lime): A large, direct-fired kiln is the industry standard for its high throughput and thermal efficiency.

- If your primary focus is waste treatment or processing sensitive materials: An indirect-fired kiln is necessary to prevent contamination and ensure a clean final product or safe disposal.

- If your primary focus is high-purity chemical synthesis or research: An electric rotary kiln provides the precise temperature control required for specialized reactions.

By mastering the flow of materials through intense heat, the rotary kiln remains one of the most powerful and versatile tools in modern industry.

Summary Table:

| Application | Primary Process | Key Industries |

|---|---|---|

| Cement & Lime Production | Calcination | Construction Materials |

| Metallurgy & Mining | Reduction Roasting | Mining & Metal Processing |

| Chemical Manufacturing | Thermal Synthesis | Chemical Industry |

| Environmental & Waste Management | Incineration & Thermal Desorption | Waste Treatment & Remediation |

Need a high-temperature furnace solution tailored to your unique process? KINTEK's advanced rotary kilns, part of our comprehensive product line including Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are engineered for precision and durability. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your specific industrial or research requirements. Contact us today to discuss how our solutions can enhance your material processing efficiency and outcomes!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How do electromagnetic induction rotary kilns simplify equipment maintenance? Enhance Uptime and Cut Costs

- What temperature can electromagnetic rotary kilns reach? Up to 1100°C for High-Efficiency Heating

- How are rotary kilns used in the beneficiation process? Unlock Efficient Iron Ore Upgrading

- How does material move through the electric heating rotary kiln? Uncover the Mechanics for Uniform Heat Processing

- What temperature does a rotary kiln get to? From 800°F to 3000°F for Your Process

- What makes electric heating advantageous in a rotary kiln electric furnace? Boost Precision and Efficiency

- What are the main components of an electric heating rotary kiln system? Discover the 5 Key Parts for Precise High-Temp Processing

- What role does the rotary kiln play in cement production? Unlocking Efficiency and Quality in Manufacturing