In a rotary kiln furnace, the primary advantages of electric heating are superior temperature precision, uniform heat distribution, and greater operational efficiency. Unlike combustion-based methods, electric elements allow for fine-tuned control over the processing environment, resulting in a higher quality and more consistent final product.

The decision to use electric heating in a rotary kiln is a strategic shift from brute-force thermal energy to precision engineering. It prioritizes process control, product purity, and automation over the lower upfront cost often associated with traditional fuel-fired systems.

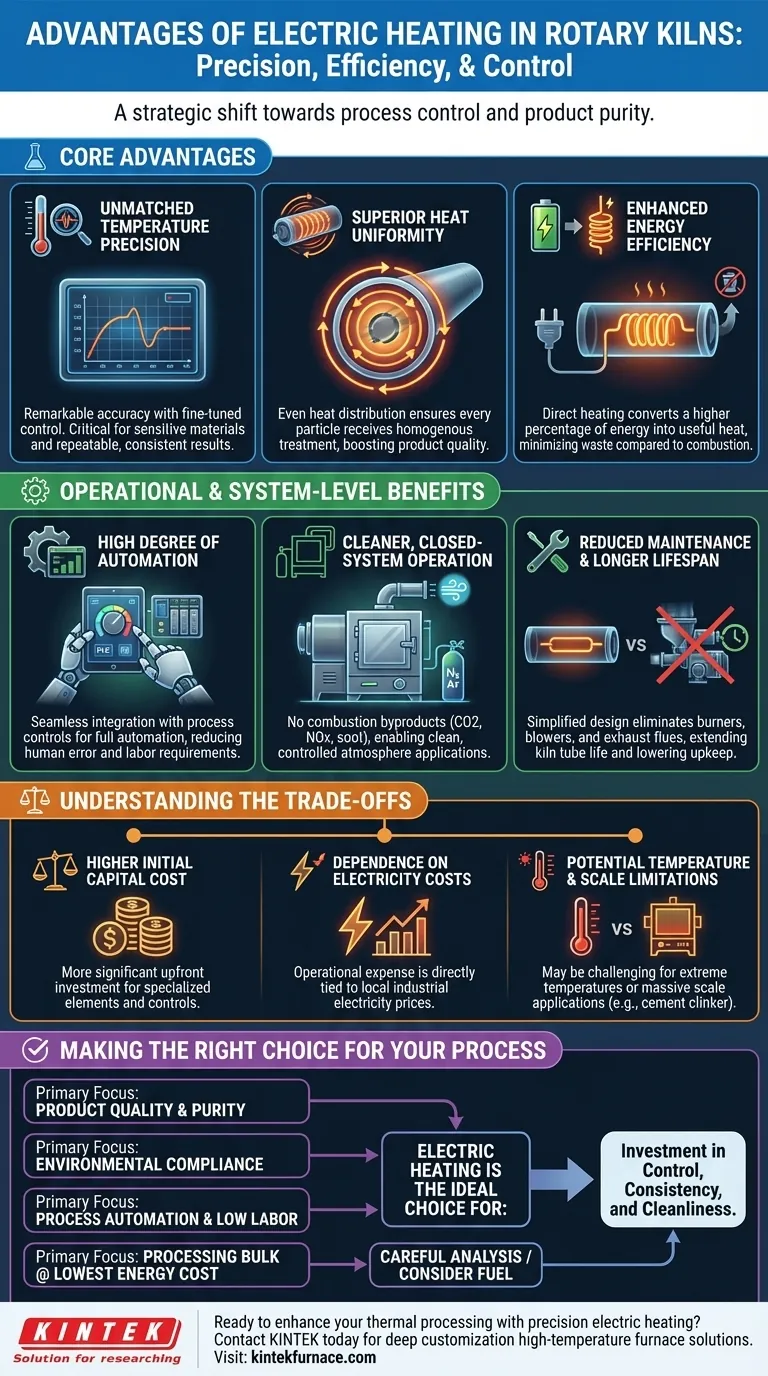

The Core Advantages of Electric Heating

Electric heating fundamentally changes how energy is delivered to the material within the kiln, offering distinct benefits that are difficult to achieve with fuel combustion.

Unmatched Temperature Precision

Electric heating elements can be controlled with remarkable accuracy. This allows for precise temperature ramps, holds, and adjustments in real-time.

This level of control is critical for processes involving sensitive materials where slight temperature deviations can ruin the final product. It ensures repeatable and predictable outcomes, batch after batch.

Superior Heat Uniformity

Electric elements can be arranged to provide exceptionally uniform heat distribution around the circumference of the kiln tube. This ensures consistent radial temperature.

As the kiln rotates, the material tumbles through a thermally stable environment, guaranteeing that every particle receives the same heat treatment. This homogeneity is essential for product quality.

Enhanced Energy Efficiency

Electric heating is a form of direct heating. A significantly higher percentage of the electrical energy is converted directly into useful heat within the kiln.

In contrast, combustion systems lose a substantial amount of energy as hot exhaust gases. By minimizing this waste, electric kilns can achieve higher overall thermal efficiency.

Operational and System-Level Benefits

Beyond the direct thermal characteristics, choosing electric heating has a cascading positive effect on the entire operation.

High Degree of Automation

Electric heating systems integrate seamlessly with modern process control systems (PLCs). Their responsiveness makes them ideal for full automation.

This reduces the need for constant operator supervision, minimizes the chance of human error, and lowers overall labor requirements.

Cleaner, Closed-System Operation

Electric heating produces no products of combustion like CO2, NOx, or soot. This allows for an inherently clean, closed-system process.

For applications requiring a controlled or inert atmosphere (e.g., using nitrogen or argon), electric heating is the only practical choice, as it doesn't introduce reactive combustion gases. This also simplifies environmental compliance by eliminating flue gas emissions.

Reduced Maintenance and Longer Lifespan

Electric kilns eliminate the complex components associated with fuel-fired systems, such as burners, fuel lines, blowers, and exhaust flues.

This simplified design not only reduces regular maintenance but also prolongs the life of the kiln tube by eliminating localized hot spots and corrosive elements from combustion.

Understanding the Trade-offs

While advantageous, electric heating is not the universal solution for every rotary kiln application. Objective analysis requires acknowledging its limitations.

Higher Initial Capital Cost

The specialized heating elements and sophisticated control systems required for an electric rotary kiln often result in a higher upfront investment compared to a conventional fuel-fired furnace.

Dependence on Electricity Costs

The operational cost of an electric kiln is directly tied to the price of industrial electricity. In regions where electricity is expensive and natural gas is cheap, a fuel-fired system may have a lower total cost of ownership.

Potential Temperature and Scale Limitations

While excellent for most applications, achieving the extreme temperatures required for certain processes (e.g., cement clinker production) on a massive industrial scale can be more challenging or cost-prohibitive with electricity compared to direct fuel combustion.

Making the Right Choice for Your Process

The decision between electric and fuel-fired heating depends entirely on your process priorities and economic constraints.

- If your primary focus is product quality and purity: The unmatched precision and clean operation of electric heating are its definitive strengths.

- If your primary focus is environmental compliance: The emission-free nature of an electric kiln simplifies permitting and eliminates the need for complex flue gas treatment.

- If your primary focus is process automation and low labor costs: The seamless integration and reliability of electric systems offer a clear advantage.

- If your primary focus is processing bulk materials at the absolute lowest energy cost: A careful analysis of local utility rates is essential, as fuel may be more economical in some areas, especially for very large-scale operations.

Ultimately, choosing electric heating is an investment in control, consistency, and cleanliness for your thermal processing operation.

Summary Table:

| Advantage | Description |

|---|---|

| Temperature Precision | Allows fine-tuned control for repeatable outcomes. |

| Heat Uniformity | Ensures consistent radial temperature for homogeneous treatment. |

| Energy Efficiency | Direct heating minimizes waste, improving thermal efficiency. |

| Automation | Integrates with PLCs for reduced labor and error. |

| Clean Operation | No combustion emissions, ideal for controlled atmospheres. |

| Reduced Maintenance | Simplified design extends lifespan and lowers upkeep. |

Ready to enhance your thermal processing with precision electric heating? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces tailored for diverse laboratories. Our strong deep customization capability ensures we meet your unique experimental needs for superior control, efficiency, and product quality. Contact us today to discuss how our solutions can benefit your operations!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions