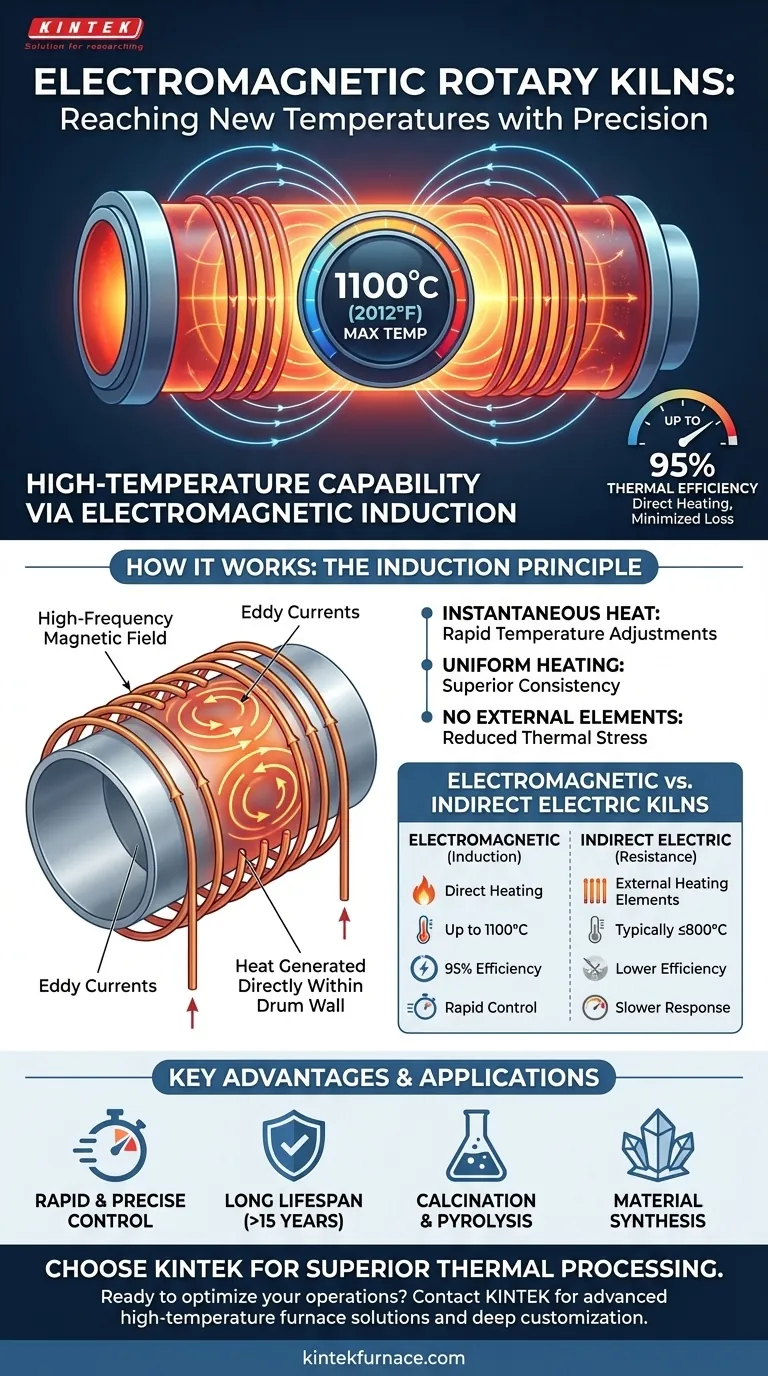

In short, electromagnetic rotary kilns are engineered to reach operating temperatures of up to 1100°C (2012°F). This high-temperature capability is a direct result of their unique heating method, which distinguishes them from many other types of electric kilns and offers significant advantages in efficiency and control.

The key takeaway is not just the maximum temperature, but how it's achieved. By using electromagnetic induction to heat the kiln drum directly, this technology provides exceptionally uniform heating, rapid temperature adjustments, and thermal efficiency that can reach up to 95%.

How Electromagnetic Kilns Achieve High Temperatures

The performance of an electromagnetic rotary kiln is rooted in the physics of induction heating. This is fundamentally different from conventional methods that rely on external burners or heating elements.

The Principle of Induction Heating

An electromagnetic kiln works by generating a high-frequency alternating magnetic field around the metallic rotary drum. This magnetic field induces electrical eddy currents directly within the wall of the drum itself.

The resistance of the metal to these currents generates intense, uniform, and instantaneous heat from the inside out. There is no external heating element; the drum becomes its own heat source.

The Advantage of Direct Heating

This direct heating method is the reason for the technology's high thermal efficiency. Since heat is generated within the material that needs to be hot, very little energy is lost to the surrounding environment.

This contrasts sharply with indirect heating, where heat must be transferred from an external source, through the kiln wall, and finally to the product inside, resulting in significant thermal losses.

Rapid and Precise Control

Because the heat is generated instantly by the magnetic field, temperature adjustments are extremely fast. Operators can increase or decrease the kiln's temperature with a level of responsiveness that is difficult to achieve with fuel-fired or indirect electric systems that have high thermal inertia.

Understanding the Operational Differences

While various electric kilns exist, the electromagnetic design occupies a specific performance niche. Its capabilities and limitations are a direct consequence of its heating mechanism.

The 1100°C Operational Ceiling

The maximum operating temperature of 1100°C is a well-established benchmark for this technology. It makes these kilns suitable for a wide range of demanding thermal processes, including calcination, pyrolysis, and material synthesis.

A Clear Distinction from Indirect Electric Kilns

It is critical not to confuse electromagnetic kilns with other types, such as electrically heated indirect rotary kilns. These more conventional designs use resistance heating elements outside the drum.

These indirect systems are often limited to lower temperatures, with some designs specifically rated for processes up to 800°C. The limitation comes from the heating elements themselves and the inefficiencies of transferring that heat into the drum.

Durability and Service Life

The absence of external combustion or ultra-high temperature heating elements reduces thermal stress on many components. This contributes to a long operational lifespan, often cited as being over 15 years, with robust safety protections built into the system.

Making the Right Choice for Your Process

Selecting the correct kiln technology requires matching its capabilities to your specific process requirements. The decision hinges on your targets for temperature, efficiency, and control.

- If your primary focus is reaching up to 1100°C with high uniformity: An electromagnetic rotary kiln is specifically designed for this performance envelope.

- If your top priority is maximizing energy efficiency and minimizing operational costs: The up to 95% thermal efficiency makes this technology a compelling choice.

- If your process requires rapid temperature changes and precise control: The instant-on/off nature of induction heating provides superior responsiveness.

- If your thermal treatment process operates at or below 800°C: A conventional indirect electric kiln may be a sufficient and viable alternative to evaluate.

Ultimately, understanding the core heating principle allows you to choose the technology that best aligns with your operational and financial goals.

Summary Table:

| Feature | Details |

|---|---|

| Maximum Temperature | Up to 1100°C (2012°F) |

| Heating Method | Electromagnetic induction |

| Thermal Efficiency | Up to 95% |

| Temperature Control | Rapid and precise adjustments |

| Key Applications | Calcination, pyrolysis, material synthesis |

| Service Life | Over 15 years |

Ready to enhance your thermal processing with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how our electromagnetic rotary kilns can optimize your operations and deliver superior performance!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules