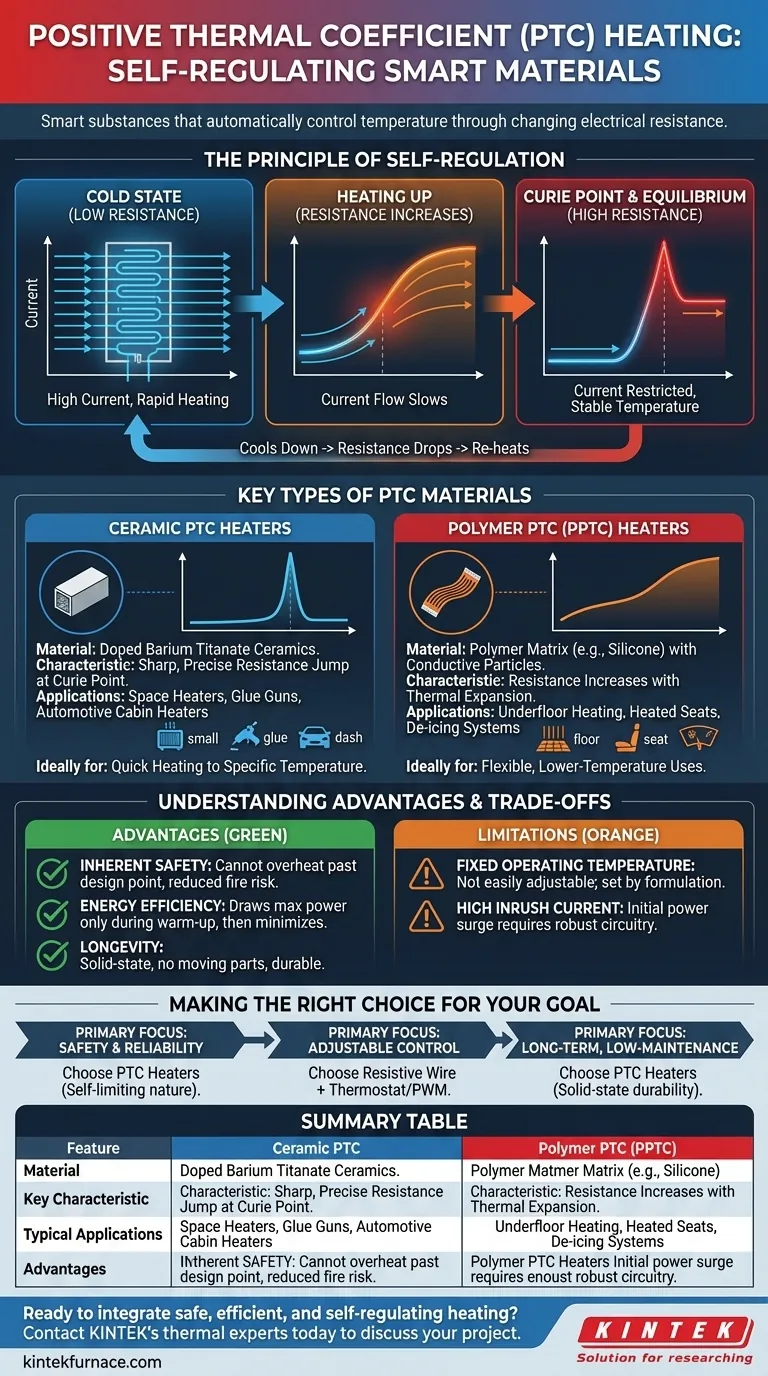

At their core, Positive Thermal Coefficient (PTC) materials are smart substances whose electrical resistance increases dramatically as their temperature rises. This unique physical property allows them to function as their own thermostat. When used as a heating element, a PTC device will heat up quickly and then automatically reduce its power consumption to maintain a stable, predetermined temperature, effectively preventing itself from overheating.

The defining characteristic of a PTC heater is not just its ability to generate heat, but its intrinsic ability to self-regulate. As it reaches its design temperature, its own resistance throttles the electrical current, providing inherent safety and impressive energy efficiency without complex external controls.

The Principle of Self-Regulation

To understand the value of PTC heaters, you must first grasp the physics behind their self-limiting behavior. This isn't a feature added on; it's a fundamental property of the material itself.

The Relationship Between Resistance and Temperature

When a PTC heater is cold, its electrical resistance is very low. According to Ohm's law, this low resistance allows a high amount of electrical current to flow through it, causing it to heat up very rapidly.

As the material's temperature increases, its resistance begins to climb. This increase in resistance starts to restrict the flow of current, which in turn slows the rate of heating.

Reaching the "Curie Point"

The most critical phase occurs at a specific temperature known as the Curie Point (or "switch temperature"). At this threshold, the material's resistance doesn't just increase—it spikes upward by several orders of magnitude.

This dramatic resistance jump severely restricts the current flow, causing heat generation to drop off sharply.

Achieving Thermal Equilibrium

The PTC heater naturally settles into a state of thermal equilibrium. It will stabilize at or near its Curie Point, only drawing enough current to generate the heat needed to offset the heat being lost to the surrounding environment.

If the ambient temperature drops, the heater cools slightly, its resistance lowers, it draws more current, and it heats back up. If the environment gets warmer, the opposite happens. This creates a stable, self-regulating thermal system.

Key Types of PTC Materials

While the principle is the same, PTC heaters are typically made from two main classes of materials, each suited for different applications.

Ceramic PTC Heaters

These are often made from doped barium titanate ceramics. They are known for their very sharp and precise resistance increase at the Curie Point.

This makes them ideal for applications requiring quick heating to a specific, stable temperature, such as in small space heaters, glue guns, or automotive cabin heaters.

Polymer PTC (PPTC) Heaters

PPTC heaters consist of a polymer matrix, like silicone rubber, infused with conductive particles such as carbon black. As the polymer heats up, it expands.

This thermal expansion forces the conductive particles apart, increasing the overall resistance of the material. These heaters are flexible and are often used in lower-temperature applications like underfloor heating, heated automotive seats, or de-icing systems.

Understanding the Advantages and Trade-offs

PTC technology offers significant benefits, but it's crucial to understand its limitations to determine if it's right for your needs.

Advantage: Inherent Safety

This is the most significant benefit. Because a PTC heater physically cannot draw enough current to overheat past its design temperature, the risk of fire is drastically reduced. Many applications can eliminate the need for complex and failure-prone thermal fuses.

Advantage: Energy Efficiency

PTC heaters only draw maximum power during the initial warm-up phase. Once at their operating temperature, their power consumption automatically drops to the minimum level needed to maintain it, making them highly efficient for maintaining a constant temperature.

Advantage: Longevity

With a solid-state design and no moving parts to wear out or burn through, PTC heaters are extremely durable and have a long operational lifespan compared to traditional resistance wire elements.

Limitation: Fixed Operating Temperature

The self-regulating temperature is determined by the material's formulation and cannot be easily adjusted. If you need a device with a wide range of variable temperature settings, a PTC heater alone may not be the right solution.

Limitation: High Inrush Current

The very low resistance of a cold PTC heater can cause a high initial surge of current. The power supply and circuitry for the device must be designed to handle this brief "inrush" current without failing.

Making the Right Choice for Your Goal

Selecting the correct heating technology depends entirely on the priorities of your project.

- If your primary focus is safety and reliability: PTC heaters are an outstanding choice due to their self-limiting nature, which intrinsically prevents overheating.

- If your primary focus is adjustable temperature control: A traditional resistive wire heater paired with a thermostat or a PWM controller will offer more flexibility.

- If your primary focus is long-term, low-maintenance operation: The solid-state durability of PTC heaters makes them a superior option for "set and forget" applications.

By understanding this principle of self-regulation, you can confidently leverage PTC technology to build safer, more durable, and more efficient thermal designs.

Summary Table:

| Feature | Ceramic PTC Heaters | Polymer PTC (PPTC) Heaters |

|---|---|---|

| Material | Doped Barium Titanate Ceramics | Polymer Matrix (e.g., Silicone) with Conductive Particles |

| Key Characteristic | Sharp, precise resistance increase at Curie Point | Resistance increases with thermal expansion |

| Typical Applications | Space Heaters, Glue Guns, Automotive Cabin Heaters | Underfloor Heating, Heated Seats, De-icing Systems |

| Advantages | Ideal for quick heating to a specific, stable temperature | Flexible, suited for lower-temperature applications |

Ready to integrate safe, efficient, and self-regulating heating into your design?

KINTEK's expertise in thermal solutions can help you select or customize the perfect PTC heating element for your application. Our team ensures you get a reliable, high-performance component tailored to your specific needs, leveraging our advanced R&D and manufacturing capabilities.

Contact our experts today to discuss your project and discover how KINTEK's heating solutions can bring superior safety and efficiency to your product.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions