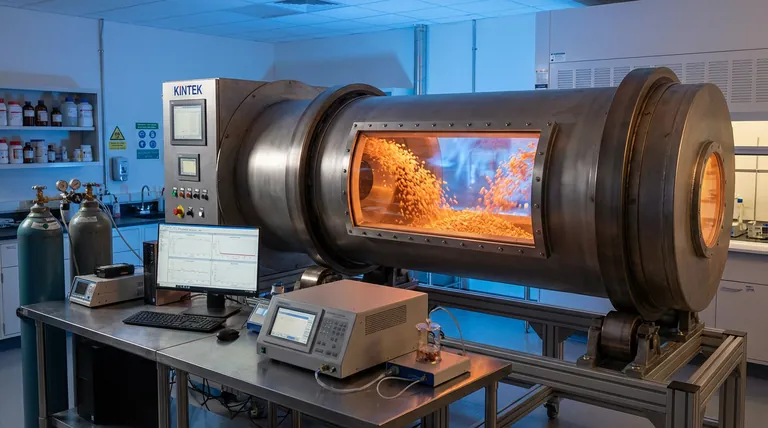

The primary advantage of a Rotary Kiln Reactor over a fixed-bed reactor lies in its ability to mechanically prevent particle clustering through continuous motion. While fixed-bed reactors keep materials static, a rotary kiln ensures that Calcium Oxide (CaO) nanoparticles are in a constant state of tumbling, allowing for superior gas-solid interaction and complete graphene encapsulation.

The mechanical rotation of the kiln solves the critical issue of powder agglomeration, ensuring that methane gas contacts the entire surface area of every particle for highly uniform carbon loading.

The Mechanics of Superior Coating

Continuous Particle Dispersion

In a static environment, nanoparticles naturally tend to clump together. The Rotary Kiln Reactor utilizes continuous rotational motion to counteract this.

By keeping the CaO nanoparticles in a constant state of tumbling, the reactor physically separates the particles. This mechanical dispersion is the foundation for achieving a high-quality composite.

Maximizing Gas-Solid Contact

The tumbling action does more than just separate particles; it exposes every surface to the reaction environment.

This dynamic movement ensures that the methane gas comes into full contact with the surface of every individual template particle. In a fixed-bed system, the gas flows around static clusters, often missing internal surfaces.

The Impact on Material Quality

Eliminating Agglomeration

The most significant barrier to effective coating is powder agglomeration. When particles stick together, they form irregular clusters that resist uniform treatment.

The rotary kiln’s mechanical action effectively prevents this agglomeration. By maintaining dispersion throughout the process, the reactor ensures that the coating process acts on individual particles rather than bulk clusters.

Achieving Uniform Carbon Loading

The ultimate result of improved dispersion and contact is complete encapsulation.

Because the methane gas can reach every surface, the CaO is coated by graphene layers without gaps. This leads to a highly uniform carbon loading across the entire material, a consistency that is difficult to replicate in static systems.

Understanding the Limitations of Fixed-Bed Systems

The Static Bed Problem

To understand the value of the rotary kiln, one must acknowledge the inherent trade-off of using a fixed-bed reactor for this specific application.

In a fixed-bed setup, the lack of motion allows particles to settle and agglomerate. This static state creates "dead zones" inside particle clusters where methane gas cannot penetrate, resulting in uneven coating and inconsistent material performance.

Making the Right Choice for Your Goal

If your project relies on high-performance graphene-coated composites, the choice of reactor mechanics is the deciding factor in material quality.

- If your primary focus is Material Homogeneity: The Rotary Kiln is essential to prevent agglomeration and ensure that every particle receives an identical coating.

- If your primary focus is Coating Completeness: The tumbling action of the Rotary Kiln provides the necessary exposure to achieve full encapsulation by graphene layers.

By replacing static processing with continuous rotational motion, you transform the coating process from a surface-level treatment into a complete, uniform encapsulation.

Summary Table:

| Feature | Rotary Kiln Reactor | Fixed-Bed Reactor |

|---|---|---|

| Material State | Continuous tumbling & motion | Static / Stationary |

| Particle Dispersion | Mechanical prevention of clumping | High risk of agglomeration |

| Gas-Solid Contact | Maximum; exposes all surfaces | Limited; gas bypasses clusters |

| Coating Quality | Complete, uniform encapsulation | Inconsistent; prone to "dead zones" |

| Product Outcome | High homogeneity & carbon loading | Irregular coating thickness |

Elevate Your Advanced Material Synthesis with KINTEK

Achieving the perfect graphene coating requires more than just chemistry—it requires precision engineering. KINTEK’s high-performance Rotary Kiln systems are designed to eliminate powder agglomeration and ensure 100% uniform gas-solid interaction for your most demanding lab applications.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need a standard setup or a fully customized high-temperature furnace tailored to your unique research needs, our team is ready to deliver the reliability you deserve.

Ready to transform your material quality? Contact KINTEK today for a consultation and let our experts help you select the ideal reactor for your laboratory.

References

- Kritin Pirabul, Hirotomo Nishihara. A thermodynamically favorable route to the synthesis of nanoporous graphene templated on CaO <i>via</i> chemical vapor deposition. DOI: 10.1039/d4gc00116h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of using a rotary reactor for carbonization? Achieve Superior Biochar Quality

- Why are rotary furnaces considered versatile industrial equipment? Unlock Efficient Material Processing

- What are the advantages of a rotary kiln for bio-reductants? Achieve Industrial-Scale Uniformity and Scalability

- What are the key components of a rotary kiln's construction? Discover the Essential Parts for Efficient Industrial Processing

- What are the key components and parameters of a rotary kiln? Optimize Your High-Temperature Processing

- What key principles make rotary kilns efficient for high-temperature processing? Unlock Optimal Thermal Processing

- What distinguishes rotary furnaces from vacuum furnaces? Choose the Right Furnace for Your Process

- What materials are used to make the rotary tube component? Choose the Right Material for Your High-Temp Needs