In short, DM Type Silicon Carbide (SiC) heating elements are workhorses in high-temperature industrial furnaces where precise and stable heat is non-negotiable. Their use is common across demanding sectors such as metal heat treatment, ceramic and glass production, semiconductor manufacturing, and aerospace component testing. These elements are chosen for their ability to deliver controlled, high-density heat reliably.

The decision to use a DM Type element is fundamentally about furnace design and heating strategy. Its rod-like shape is engineered for insertion through furnace walls, providing intense, direct radiant heat into a specific processing zone.

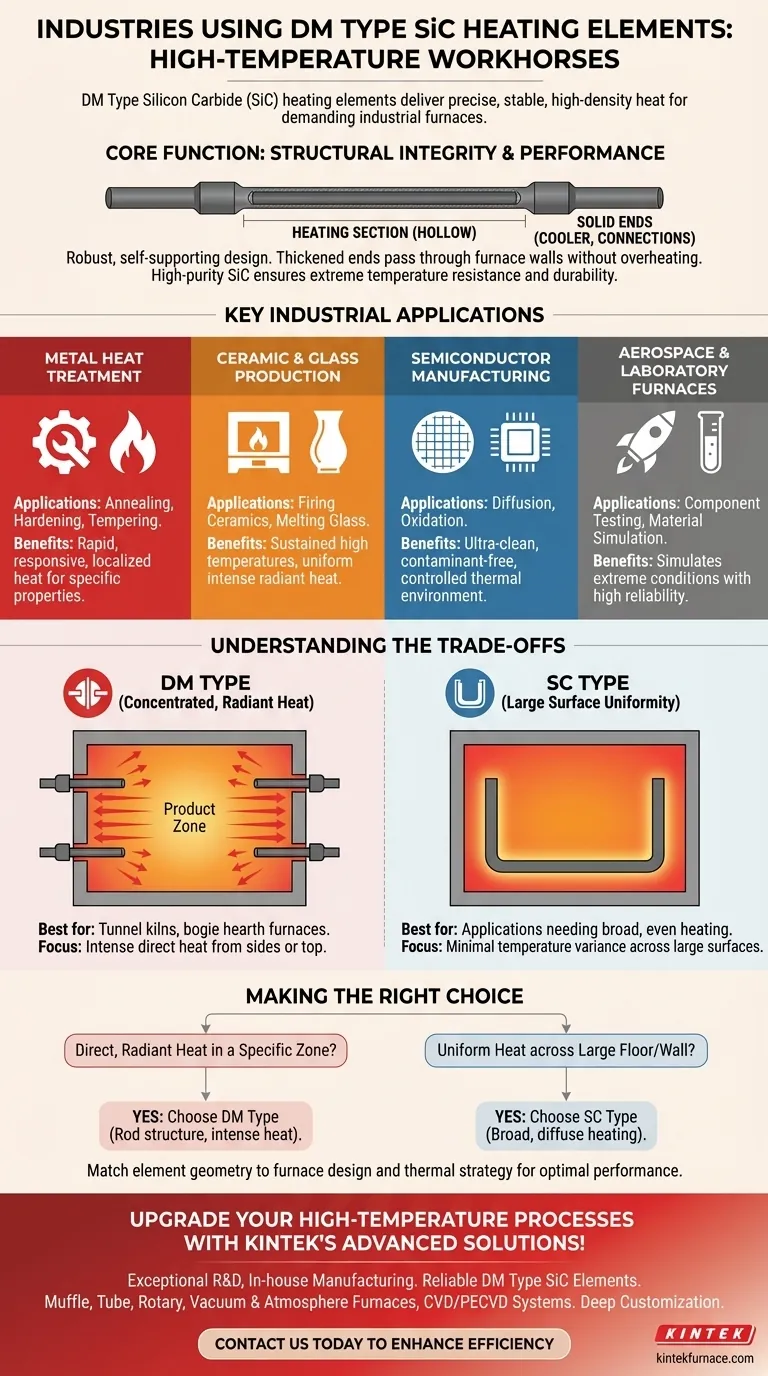

The Core Function of DM Type SiC Elements

To understand where these elements are used, you must first understand their design. Their form dictates their function and makes them ideal for certain types of industrial furnaces.

A Focus on Structural Integrity

DM Type elements consist of a hollow tubular heating section with two thickened, solid ends. This design is robust and self-supporting.

The thickened ends serve as the electrical connection points and remain cooler, allowing the element to pass through the furnace's insulated walls without overheating them.

High-Temperature Performance

Composed of high-purity, self-bonded silicon carbide, these elements can operate at extremely high temperatures. Their material properties allow them to withstand the harsh thermal cycling common in industrial processes.

This durability ensures a long service life and predictable performance, which is critical for minimizing downtime in continuous production environments.

Key Industrial Applications Explained

The unique characteristics of DM Type elements make them a preferred choice in several key industries that rely on precision thermal processing.

Metal Heat Treatment

In processes like annealing, hardening, and tempering, metals must be heated to exact temperatures. DM Type elements provide the rapid, responsive, and localized heat required to achieve specific metallurgical properties.

Ceramic and Glass Production

The manufacturing of ceramics, technical glass, and float glass requires sustained, very high temperatures. DM elements are installed in kilns and furnaces to provide the intense radiant heat needed to fire ceramics or melt glass ingredients uniformly.

Semiconductor Manufacturing

Creating semiconductor wafers involves processes like diffusion and oxidation, which demand an ultra-clean and meticulously controlled thermal environment. The stable and contaminant-free heating from SiC elements is essential for achieving the required purity and quality.

Aerospace and Laboratory Furnaces

DM elements are also used in laboratory settings and for testing aerospace components. They can effectively simulate the extreme temperature environments that materials and parts will face during operation, ensuring reliability and safety.

Understanding the Trade-offs: DM Type vs. Other Designs

The DM Type is not a universal solution. Choosing the right heating element requires understanding its strengths in comparison to other available designs, such as the SC Type.

DM Type for Concentrated, Radiant Heat

The primary advantage of the DM Type is its ability to be inserted horizontally or vertically through the furnace wall. This placement allows it to radiate heat directly and intensely onto the product.

This design is ideal for tunnel kilns, bogie hearth furnaces, and any application where heating from the sides or top is most effective.

SC Type for Large Surface Uniformity

In contrast, an SC (or U-Type) element is often used for bottom or side heating across large areas. It is better suited for applications where broad, even heating from a large surface is needed to ensure minimal temperature variance.

Choosing between them depends entirely on whether you need to heat a large, flat area from below or radiate heat into a chamber from the sides.

Making the Right Choice for Your Goal

Your furnace design and process requirements are the ultimate deciding factors. To select the correct element, you must match its geometry to your heating strategy.

- If your primary focus is direct, radiant heat in a specific zone: The DM Type's self-supporting rod structure, inserted through the furnace wall, is the ideal solution.

- If your primary focus is uniform heat across a large furnace floor or wall: An SC Type element, which provides broader, more diffuse heating, is likely the more appropriate choice.

Ultimately, understanding your furnace's design and thermal requirements is the key to selecting the most effective and efficient heating element.

Summary Table:

| Industry | Key Applications | Benefits of DM Type SiC Elements |

|---|---|---|

| Metal Heat Treatment | Annealing, hardening, tempering | Precise temperature control, rapid heating |

| Ceramic and Glass Production | Firing ceramics, melting glass | High-temperature stability, uniform heating |

| Semiconductor Manufacturing | Diffusion, oxidation processes | Contaminant-free, stable thermal environment |

| Aerospace and Laboratory Testing | Component testing, material simulation | Durability, reliable performance in extreme conditions |

Upgrade your high-temperature processes with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable DM Type Silicon Carbide Heating Elements and other products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance efficiency and performance in your industry!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism