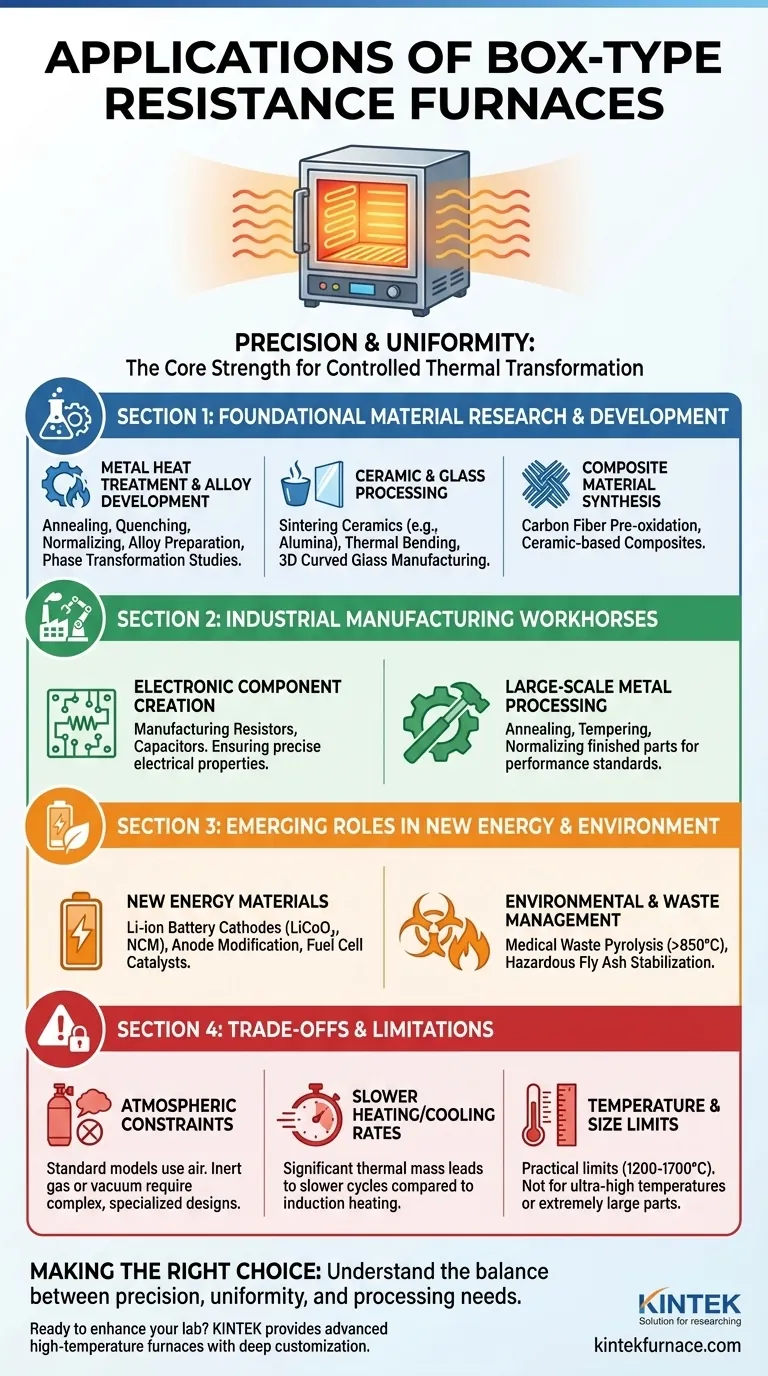

In essence, box-type resistance furnaces are a cornerstone of modern material science and industrial processing. They are widely used across foundational scientific research, diverse industrial manufacturing sectors, and critical new fields like new energy and environmental protection. Their primary function is to provide a highly controlled, high-temperature environment for transforming materials.

The true value of a box-type resistance furnace lies not merely in its ability to generate heat, but in its capacity to deliver that heat with exceptional uniformity and precision. This simple yet powerful characteristic makes it an indispensable and versatile tool for any process that relies on controlled thermal transformation.

Foundational Use in Material Research and Development

The furnace's operational flexibility makes it a default choice in laboratories for exploring and creating new materials. Researchers rely on its predictable performance to test hypotheses and perfect material properties.

Metal Heat Treatment and Alloy Development

Nearly all metallic material research involves a box furnace. It's used for fundamental heat treatment processes like annealing, quenching, and normalizing to precisely alter a metal's hardness, toughness, or plasticity.

It is also crucial for alloy preparation, where controlling temperature gradients ensures uniform diffusion of elements, and for studying phase transformations by observing how crystal structures change at specific high temperatures.

Ceramic and Glass Processing

Box furnaces are essential for sintering ceramics, a process where powdered materials like alumina are heated to bond and densify into a hard, solid object.

In glass processing, they enable thermal bending and melting. A key example is the manufacturing of 3D curved glass for mobile phone screens, which requires uniform heat to shape the glass without introducing stress or defects.

Composite Material Synthesis

The furnace is also used for developing advanced composites. This includes processes like the pre-oxidation of carbon fibers or the synthesis of ceramic-based composite materials, where precise temperature stages are critical for the final material's integrity.

Core Applications in Industrial Manufacturing

Beyond the lab, box-type resistance furnaces are workhorses in various industrial production environments, valued for their simple structure and reliable operation.

Manufacturing of Electronic Components

The creation of many basic electronic components, such as resistors and capacitors, depends on precise thermal processing. A box furnace provides the stable heating environment necessary to achieve the desired electrical properties in these components during manufacturing.

Large-Scale Metal Processing

The same heat treatment principles from R&D are applied on a larger scale in manufacturing. Furnaces are used for annealing, tempering, and normalizing finished metal parts to ensure they meet required performance and durability standards.

Emerging Roles in Energy and Environmental Tech

As technology advances, the applications for this fundamental tool have expanded into solving modern energy and environmental challenges.

New Energy Materials

In the new energy sector, box furnaces are critical for producing battery materials. This includes the high-temperature solid-phase synthesis of cathode materials like LiCoO₂ (LCO) and NCM ternary materials used in lithium-ion batteries.

They are also used to modify graphite anode materials and prepare the catalytic materials (e.g., Pt/Al₂O₃) that are essential for fuel cells and emissions control systems.

Environmental and Waste Management

For environmental protection, these furnaces provide a high-temperature solution for waste treatment. They are used for the pyrolysis incineration of medical waste at temperatures above 850°C, ensuring its harmless decomposition.

They also help in stabilizing hazardous fly ash from incinerators by melting it at high temperatures, which traps heavy metals within a stable, glass-like matrix.

Understanding the Trade-offs and Limitations

While highly versatile, the box-type resistance furnace is not the universal solution for every heating task. Understanding its inherent trade-offs is key to using it effectively.

Not Ideal for Reactive Atmospheres

A standard box-type resistance furnace operates in an air atmosphere. Processes that require an inert gas (like Argon) or a vacuum to prevent oxidation or other reactions demand more complex and expensive furnace designs with specialized sealing and gas-handling capabilities.

Slower Heating and Cooling Rates

The design relies on resistance elements heating a chamber, which has significant thermal mass. This results in slower heating and cooling cycles compared to technologies like induction or microwave heating. For high-volume production requiring rapid cycles, this can be a significant bottleneck.

Temperature and Size Constraints

Standard models have practical temperature limits, typically topping out around 1200°C to 1700°C depending on the heating elements used. Applications requiring ultra-high temperatures or the processing of extremely large industrial parts may necessitate different furnace technologies, such as arc or induction furnaces.

Making the Right Choice for Your Goal

To determine if a box-type resistance furnace is the correct tool, consider your primary objective.

- If your primary focus is foundational research or material property testing: A box furnace is an ideal and versatile tool due to its excellent temperature uniformity and precise control.

- If your primary focus is high-volume manufacturing with rapid cycling: You should evaluate if the heating and cooling rates of a resistance furnace meet your throughput needs compared to faster alternatives.

- If your primary focus is processing in a controlled, non-air atmosphere: You must source a specialized box furnace designed with vacuum or inert gas capabilities, as a standard model will not suffice.

Ultimately, understanding the furnace's core strengths—precision and uniformity—is the key to leveraging it effectively across countless scientific and industrial challenges.

Summary Table:

| Field | Key Applications |

|---|---|

| Material Research & Development | Metal heat treatment, alloy development, ceramic sintering, glass processing, composite material synthesis |

| Industrial Manufacturing | Electronic component production, large-scale metal processing (annealing, tempering) |

| Energy & Environmental Tech | Battery material synthesis (e.g., LiCoO₂), waste pyrolysis, hazardous fly ash stabilization |

| Limitations | Not for reactive atmospheres, slower heating/cooling rates, temperature/size constraints |

Ready to enhance your lab's capabilities with a high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior performance and efficiency. Contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What happens to convective and radiative heat transfer effects at high furnace gas temperatures? Radiation Dominates for Superior Heating