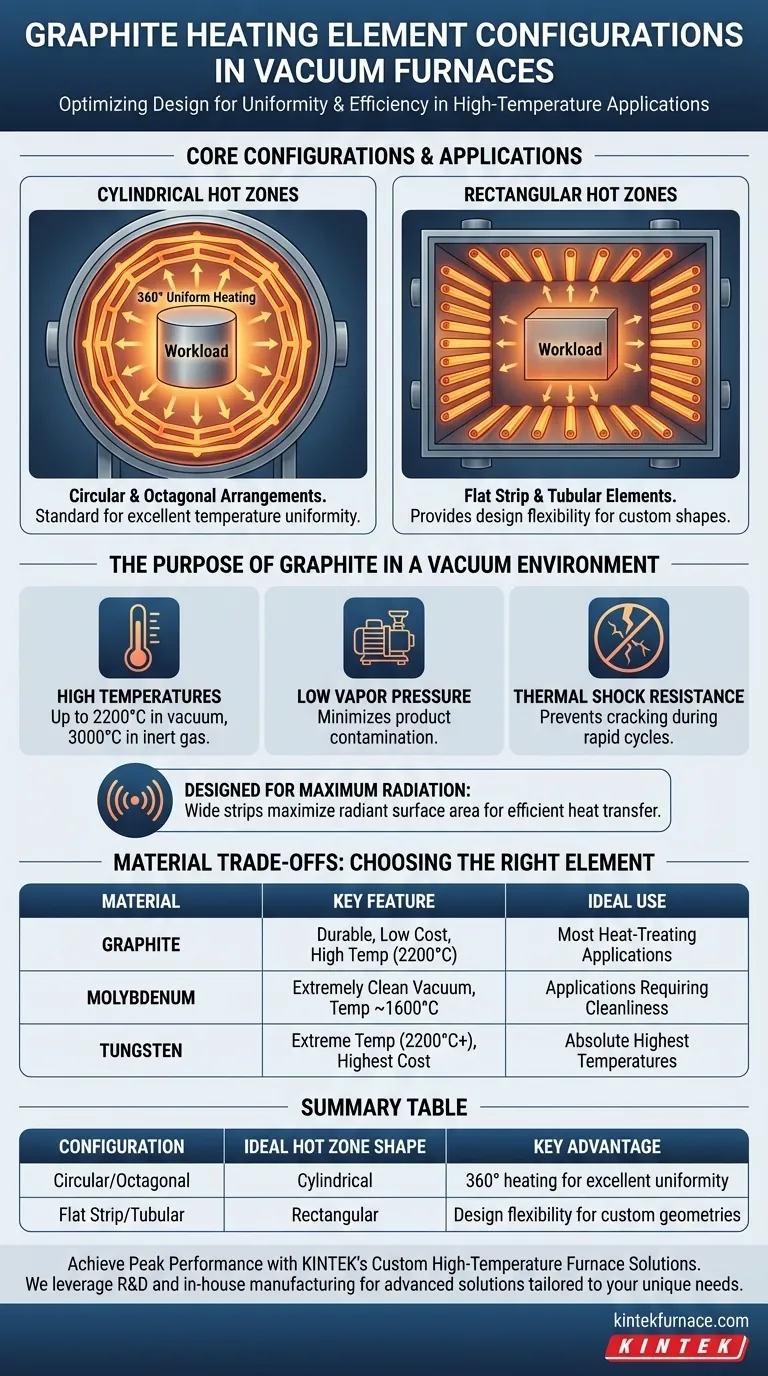

In a vacuum furnace, graphite heating elements are most commonly arranged in 360° circular or octagonal configurations for cylindrical hot zones. For rectangular hot zones, designers utilize flat strip or tubular element forms to achieve the same goal of uniform, efficient heating.

The physical arrangement of a graphite heating element is not arbitrary; it is a deliberate design choice driven by the geometry of the furnace's hot zone to maximize radiant surface area and ensure exceptional temperature uniformity.

The Purpose of Graphite in a Vacuum Environment

Before examining specific configurations, it is crucial to understand why graphite is a superior material for this application. Its properties make it uniquely suited for the harsh, high-temperature conditions of a vacuum furnace.

Key Properties for Vacuum Operation

Graphite can operate at extremely high temperatures—up to 2200°C in a vacuum and even 3000°C in an inert gas atmosphere.

It has a very low vapor pressure, which is critical for minimizing the contamination of the product within the vacuum.

Furthermore, graphite offers excellent resistance to thermal shock, preventing it from cracking during rapid heating and cooling cycles.

Designed for Maximum Radiation

Heating in a vacuum is primarily achieved through radiation. Therefore, elements are often designed as wide strips or ribbons.

This shape maximizes the physical surface area, which in turn creates a large radiant surface area for the most efficient transfer of heat to the workload.

Evolution of Modern Graphite Elements

Early graphite elements were bulky and prone to failure at their electrical connections.

Modern advancements in material science and manufacturing have overcome these issues. Today's graphite is a highly reliable and accepted material, known for its long service life and chemical inertness.

Core Configurations and Their Applications

The choice of configuration directly corresponds to the shape of the furnace's hot zone. The goal is always to surround the workload for even heating.

Circular and Octagonal Arrangements

These are the most common configurations, providing 360° heating coverage.

They are the standard for furnaces with a cylindrical hot zone, ensuring that heat radiates evenly from all directions toward the center. This design is renowned for delivering excellent temperature uniformity.

Flat Strip and Tubular Elements

When a furnace requires a rectangular hot zone, circular designs are impractical.

In these cases, flat strips or tubular elements are arranged to line the walls of the hot zone. This provides the necessary design flexibility while still achieving uniform heat distribution across a non-cylindrical space.

Understanding the Material Trade-offs

While graphite is often the default choice, it is one of several materials used for vacuum furnace heating elements. Understanding the alternatives provides critical context for its selection.

Graphite: The Durable Workhorse

Graphite is selected for its durability, comparatively low cost, and ability to handle very high temperatures (up to 2200°C). It is the most common choice for a wide range of heat-treating applications.

Molybdenum: The Cleanliness Specialist

Molybdenum is used in applications where an extremely clean vacuum environment is paramount, as it has an even lower vapor pressure than graphite. Its temperature limit is typically around 1600°C.

Tungsten: The Extreme Temperature Expert

For applications requiring the absolute highest temperatures, tungsten is the material of choice, capable of withstanding up to 2200°C or more. It is generally the most expensive option.

Making the Right Choice for Your Furnace

Your optimal configuration depends on your furnace's physical design and the specific requirements of your process.

- If your primary focus is a standard cylindrical hot zone: A 360° circular or octagonal graphite configuration is the industry standard for ensuring uniform heating.

- If your primary focus is a custom or rectangular hot zone: Flat strip or tubular graphite elements offer the necessary design flexibility for these specific geometries.

- If your primary focus is cost-effective durability for most applications: Graphite remains the go-to material choice over more specialized metals.

- If your primary focus is an exceptionally clean process or extreme temperatures: You may need to evaluate the trade-offs of using molybdenum or tungsten instead of graphite.

Ultimately, aligning the heating element's material properties and physical geometry with your furnace design is the key to achieving an efficient and reliable thermal process.

Summary Table:

| Configuration | Ideal Hot Zone Shape | Key Advantage |

|---|---|---|

| Circular/Octagonal | Cylindrical | 360° heating for excellent uniformity |

| Flat Strip/Tubular | Rectangular | Design flexibility for custom geometries |

Achieve Peak Performance with KINTEK's Custom High-Temperature Furnace Solutions

Selecting the right graphite heating element configuration is critical for your vacuum furnace's efficiency and temperature uniformity. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, custom high-temperature furnace solutions tailored to your unique experimental requirements.

Our extensive product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities. Whether you need a standard cylindrical hot zone with 360° heating or a custom rectangular design, we engineer the perfect solution for your lab.

Ready to optimize your thermal process? Contact our experts today to discuss how our durable, high-performance graphite heating elements can enhance your application.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency