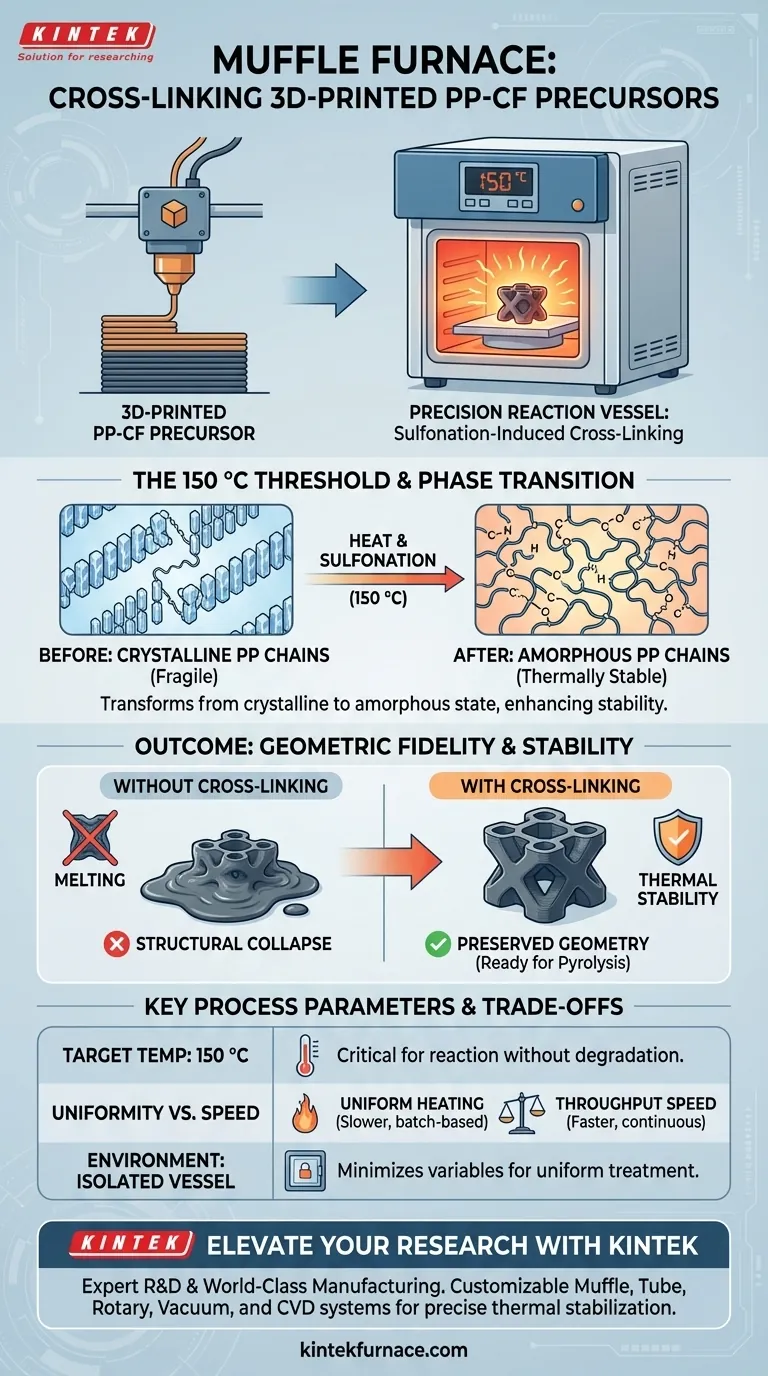

In the processing of 3D-printed polypropylene-carbon fiber (PP-CF) precursors, the laboratory high-temperature muffle furnace serves as a precision reaction vessel for sulfonation-induced cross-linking. Its primary function is to maintain a rigorous, constant temperature of 150 °C, creating the stable thermochemical environment required to chemically alter the polymer matrix.

The muffle furnace facilitates a critical phase change, converting polypropylene chains from a crystalline to an amorphous state. This transformation significantly enhances thermal stability, ensuring the 3D-printed geometry does not melt or collapse during subsequent high-temperature pyrolysis.

The Role of Thermal Precision in Cross-Linking

Stabilizing the Thermochemical Environment

The cross-linking process for PP-CF is chemically sensitive. The muffle furnace provides a stable thermochemical environment necessary for sulfonation to occur uniformly throughout the sample.

Unlike open-air heating, the muffle furnace isolates the reaction. This isolation minimizes external variables, allowing the sulfonation process to proceed efficiently.

The 150 °C Threshold

Success hinges on maintaining a specific temperature setpoint of 150 °C. This temperature is calibrated to drive the chemical reaction without degrading the material components.

At this precise temperature, the furnace supplies enough energy to initiate the necessary molecular changes. Deviating from this specific thermal value can compromise the precursor's readiness for later stages.

Modifying the Polymer Structure

From Crystalline to Amorphous

The core biological change achieved in the furnace is the transformation of polypropylene chains. The heat treatment transitions these chains from a crystalline state to an amorphous state.

This phase transition is essential for the material's future durability. It fundamentally alters how the polymer responds to heat, preparing it for much higher temperatures later in the manufacturing workflow.

Preventing Structural Collapse

The ultimate goal of this furnace treatment is preserving the three-dimensional structural integrity of the print.

Without this cross-linking step, the polypropylene would likely melt and lose its shape during pyrolysis. The furnace effectively "locks in" the shape, allowing the precursor to survive subsequent high-temperature processing.

Understanding the Trade-offs

Temperature Sensitivity Risks

While the muffle furnace is designed for stability, the process at 150 °C operates within a tight window.

If the temperature fluctuates significantly below this point, the transition to the amorphous state may be incomplete, leading to structural failure later. Conversely, excessive heat spikes could induce premature melting before cross-linking is established.

Uniformity vs. Speed

A muffle furnace is excellent for creating a uniform thermal field, ensuring the entire part is treated equally. However, this is generally a slower, batch-based process compared to continuous heating methods.

You trade the speed of throughput for the assurance that the heat distribution is even, preventing internal stresses or warping in the 3D-printed part.

Making the Right Choice for Your Goal

To maximize the effectiveness of the cross-linking process, consider your specific manufacturing objectives:

- If your primary focus is Geometric Fidelity: Ensure your furnace is calibrated strictly to 150 °C to lock in the shape before the polymer can flow or distort.

- If your primary focus is Pyrolysis Preparation: Verify the duration of the furnace dwell time to guarantee the full transition from crystalline to amorphous chains.

The muffle furnace is not just a heater; it is the stabilization tool that bridges the gap between a fragile plastic print and a durable carbonized component.

Summary Table:

| Process Parameter | Requirement/Outcome | Significance in PP-CF Processing |

|---|---|---|

| Target Temperature | 150 °C | Drives chemical reaction without degrading material. |

| Phase Transition | Crystalline to Amorphous | Enhances thermal stability for subsequent pyrolysis. |

| Structural Goal | Geometric Fidelity | Prevents melting or collapse of 3D-printed geometry. |

| Environment | Isolated Reaction Vessel | Minimizes variables for uniform sulfonation. |

Elevate Your Advanced Material Research with KINTEK

Precise thermal stabilization is the difference between a collapsed 3D print and a high-performance carbonized component. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems.

Our laboratory high-temperature furnaces are fully customizable to meet the rigorous demands of sulfonation, cross-linking, and pyrolysis. Whether you are scaling up 3D-printed PP-CF production or developing new polymer precursors, KINTEK provides the uniform heating and temperature precision your lab requires.

Ready to optimize your thermal processing? Contact us today to discuss your unique needs.

Visual Guide

References

- Paul N. Smith, Zhe Qiang. Transformative 3D Printing of Carbon‐metal Nanocomposites as Catalytic Joule Heaters for Enhanced Ammonia Decomposition. DOI: 10.1002/advs.202413149

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the key aspects to consider when choosing a muffle furnace? Ensure Optimal Performance and Safety

- How does a laboratory muffle furnace contribute to the transformation of biomass into carbon precursors? Expert Guide

- What ensures heating uniformity in box type high-temperature resistance furnaces? Achieve Consistent Thermal Processing

- What personal protective equipment (PPE) should be worn when operating a muffle furnace? Ensure Complete Lab Safety

- What makes the muffle furnace's heating environment unique compared to other furnaces? Discover the Key to Contamination-Free Heating

- What conditions does a muffle furnace provide for evaluating the oxidation stability of HfOC/SiOC fiber mats?

- What is the typical operating temperature range for Box Furnaces? Find Your Perfect Heat Solution

- Industrial Applications of High-Temperature Furnaces for Biochar Analysis: Precision Control & Efficiency