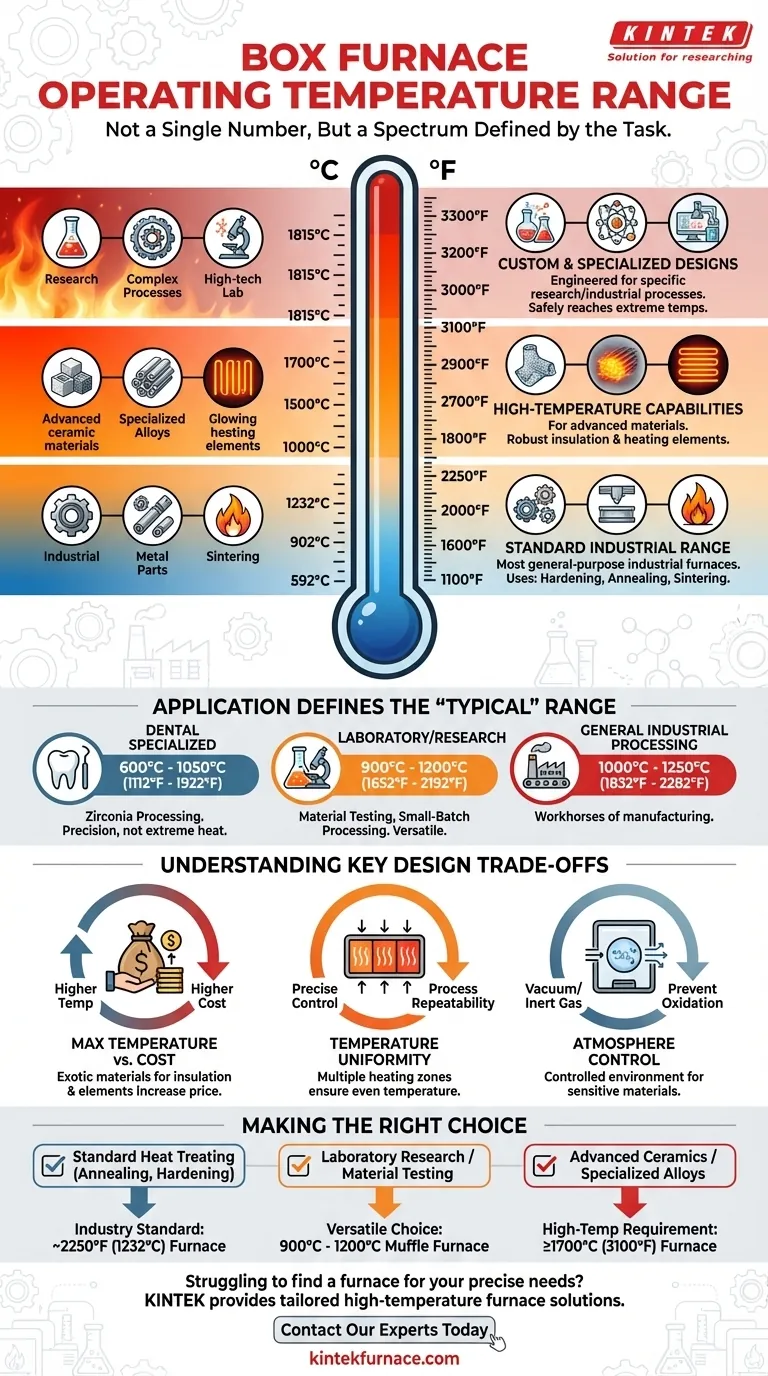

At its core, a box furnace's typical operating temperature range is designed for high-heat applications, generally starting above 1100°F (592°C). While standard industrial models commonly operate up to 2250°F (1232°C), the "typical" range varies significantly based on the specific application, with laboratory and custom units reaching much higher temperatures.

The key takeaway is that "typical operating temperature" is not a single number but a spectrum defined by the task. While most industrial processes fall within a standard high-heat range, specialized applications in labs or advanced manufacturing demand furnaces with capabilities extending from 1700°C (3100°F) to over 1800°C (3300°F).

Defining the Operating Spectrum of Box Furnaces

Understanding the temperature capabilities of a box furnace requires looking at three distinct tiers: the standard workhorse range, the high-temperature range for advanced materials, and the custom-engineered solutions for unique processes.

The Standard Industrial Range

Most general-purpose industrial box furnaces operate in a range between 1100°F (592°C) and 2250°F (1232°C).

This temperature band is sufficient for a wide variety of common thermal processes, including hardening, annealing, and sintering of many metals and materials.

High-Temperature Capabilities

For applications involving advanced materials like ceramics or specific metal alloys, high-temperature box furnaces are required.

These units typically operate in a range from 1000°C (1800°F) up to 1700°C (3100°F). They are engineered with more robust insulation and heating elements to reliably sustain these intense temperatures.

Custom and Specialized Designs

At the highest end of the spectrum are custom-engineered furnaces built for highly specific research or industrial processes.

These designs can be modified to safely and precisely reach temperatures as high as 3300°F (approximately 1815°C), accommodating the most demanding thermal requirements.

How Application Defines the "Typical" Range

The term "typical" is best understood by looking at the specific field where the furnace is used. The required temperature range for a dental lab is vastly different from that of an aerospace materials facility.

General Industrial Processing

For broad industrial heat treatment, the most common and practical range is between 1000°C and 1250°C. Furnaces in this category are the workhorses of the manufacturing sector.

Laboratory and Research Use

Laboratory box furnaces, often called muffle furnaces, offer versatility for testing and small-batch processing.

While they can be designed for temperatures up to 1750°C, the most common usage falls between 900°C and 1200°C (1652°F to 2192°F).

Specialized Dental Furnaces

Dental applications for processing materials like zirconia require precision but not extreme heat.

These specialized furnaces typically operate in a much lower and narrower range, from 600°C to 1050°C (1112°F to 1922°F).

Understanding the Key Design Trade-offs

Choosing a furnace isn't just about finding the highest maximum temperature. The design involves critical trade-offs between temperature, precision, and cost.

Maximum Temperature vs. Cost

Higher operating temperatures demand more exotic and durable materials for insulation and heating elements. As a result, a furnace rated for 1800°C will be significantly more expensive than a standard model that maxes out at 1250°C.

Temperature Uniformity

Achieving a high temperature is one challenge; maintaining it evenly across the entire chamber is another. High-performance furnaces often use multiple heating zones to ensure precise and uniform temperature control, which is critical for process repeatability.

Atmosphere Control

The operating temperature is only one part of the equation. Many advanced processes require a controlled atmosphere, such as a vacuum or inert gas, to prevent oxidation. A vacuum furnace, for instance, combines high-heat capability (up to 1600°C) with atmosphere control for treating sensitive materials.

Making the Right Choice for Your Goal

To select the correct furnace, focus on the specific requirements of your thermal process rather than a generic "typical" range.

- If your primary focus is standard industrial heat treating (e.g., annealing, hardening): A furnace with a maximum temperature around 2250°F (1232°C) is the industry standard and most cost-effective choice.

- If your primary focus is laboratory research or material testing: A versatile muffle furnace with a common operating range of 900°C to 1200°C will cover most experimental needs.

- If your primary focus is processing advanced ceramics or specialized alloys: You will need a high-temperature furnace capable of reaching or exceeding 1700°C (3100°F) to meet material requirements.

Matching the furnace's temperature capability to your specific material and process is the key to achieving reliable, efficient, and repeatable results.

Summary Table:

| Application Type | Typical Operating Range | Common Use Cases |

|---|---|---|

| Standard Industrial | 1100°F - 2250°F (592°C - 1232°C) | Hardening, Annealing, Sintering |

| Laboratory/Research | 900°C - 1200°C (1652°F - 2192°F) | Material Testing, Small-Batch Processing |

| High-Temperature | Up to 1700°C (3100°F) | Advanced Ceramics, Specialized Alloys |

| Dental Specialized | 600°C - 1050°C (1112°F - 1922°F) | Zirconia Processing |

Struggling to find a box furnace that meets your precise temperature and application needs?

At KINTEK, we understand that 'typical' isn't good enough. Your research or manufacturing process demands a furnace tailored to your exact thermal requirements—whether it's uniform heating at 1200°C or pushing the limits at 1800°C.

Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let's engineer your ideal heat treatment solution. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.