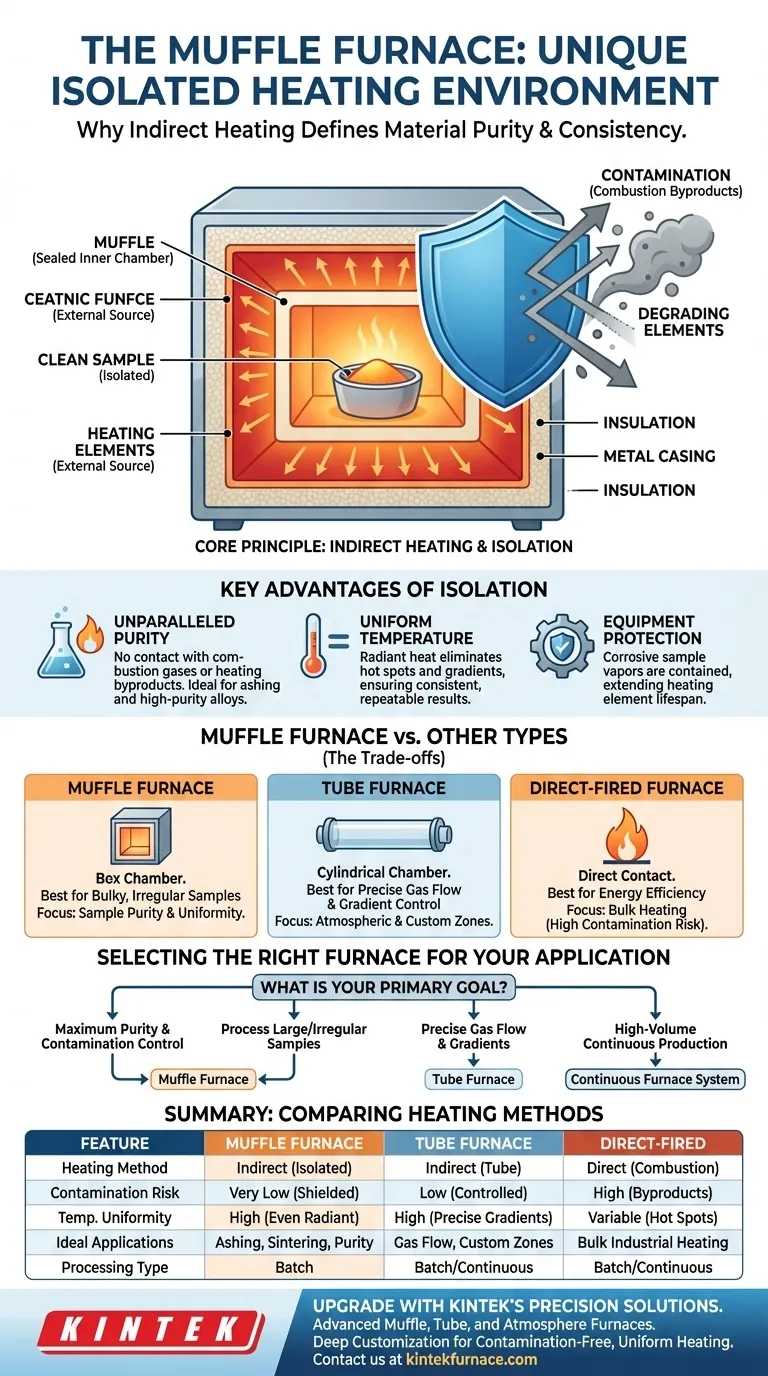

At its core, the muffle furnace’s unique heating environment comes from a single design principle: isolation. It uses an insulated outer chamber to heat a sealed inner chamber—the "muffle"—which holds the material. This method of indirect heating prevents any contact between the sample and the actual heating elements or combustion byproducts, creating an exceptionally clean and controlled atmosphere.

The defining feature of a muffle furnace is not just its ability to reach high temperatures, but its method of doing so through indirect heating. This creates a contamination-free, uniform thermal environment, making it the definitive choice for processes where material purity and consistency are paramount.

The Principle of Indirect Heating

The term "muffle" refers to the furnace's sealed inner chamber, which acts as a barrier. This fundamental design element is responsible for its unique heating characteristics.

What is the "Muffle"?

The muffle is a box-like enclosure, typically made of high-temperature ceramic, that contains the sample. Heating elements on the outside heat this chamber, which then radiates thermal energy evenly inward.

The sample inside never "sees" the raw heat source. Think of it like a perfectly sealed cooking pot placed inside a larger, hotter oven.

Preventing Contamination

The primary benefit of this design is the creation of a contamination-free environment. In direct-fired furnaces, byproducts of combustion or particles from degrading heating elements can settle on and corrupt the sample.

The muffle acts as an impassable shield, ensuring that the only thing interacting with the sample is pure, radiant heat. This is critical for sensitive analytical work like ashing or for creating high-purity alloys.

Ensuring Uniform Temperature

By heating the entire exterior of the muffle, the furnace distributes thermal energy evenly throughout the inner chamber. This design minimizes temperature gradients and "hot spots" that can occur in other heating systems.

For processes like annealing or sintering, where even a slight temperature variation can alter a material's properties, this uniformity guarantees consistent and repeatable results across the entire sample.

Key Advantages of the Muffle Design

The muffle's isolated environment provides several distinct operational advantages that make it indispensable in laboratory and specialized industrial settings.

High Purity for Sensitive Processes

The clean heating environment is ideal for tasks like ashing food or chemical samples, where the goal is to burn off organic material to measure the remaining inorganic content without introducing external contaminants.

It is also essential for sintering powdered metals and ceramics, where purity directly affects the final strength and integrity of the material.

Consistent and Repeatable Results

Because the furnace eliminates temperature fluctuations, every batch processed under the same settings will experience the same thermal conditions. This repeatability is a non-negotiable requirement for quality control and scientific research.

Protecting the Furnace Itself

The isolation works both ways. Vapors or corrosive gases released by the sample during heating are contained within the muffle.

This protects the furnace’s expensive heating elements from degradation, significantly extending the lifespan and reliability of the equipment.

Understanding the Trade-offs: Muffle vs. Other Furnaces

While powerful, the muffle furnace is not the right tool for every job. Its design creates specific trade-offs when compared to other types of furnaces.

Muffle Furnace vs. Tube Furnace

Both furnace types offer clean, controlled atmospheres. The primary difference is geometry. A muffle furnace has a large, boxy chamber ideal for processing bulky or irregularly shaped samples.

A tube furnace, with its cylindrical chamber, offers more precise control over gas flow and temperature gradients. This makes it superior for processes that require a specific atmospheric flow over the sample or highly customized heating and cooling zones.

Muffle Furnace vs. Direct-Fired Furnace

A direct-fired furnace is often more energy-efficient, as heat is applied directly to the workload. However, this comes at the cost of potential contamination from combustion gases.

A muffle furnace prioritizes sample purity over maximum thermal efficiency, making it the choice for precision work over bulk industrial heating.

Batch vs. Continuous Processing

Muffle furnaces are inherently batch processing units. A sample is placed inside, the door is sealed, and it runs through a heating cycle.

This is in contrast to continuous systems like a pusher furnace, where materials are constantly moved through different heating zones. Such systems are built for high-volume manufacturing, not the precise, stationary heating of a muffle furnace.

Making the Right Choice for Your Application

Selecting the correct heating equipment depends entirely on your primary process goal.

- If your primary focus is maximum purity and contamination control: The isolated chamber of a muffle furnace is the ideal solution.

- If your primary focus is processing large or irregularly shaped samples: The muffle furnace’s spacious box chamber provides more flexibility than a tube furnace.

- If your primary focus is precise gas flow and temperature gradient control: A tube furnace is often the superior choice due to its geometry.

- If your primary focus is high-volume, continuous production: A dedicated continuous furnace system is necessary, as a muffle furnace is designed for batch work.

Ultimately, choosing a muffle furnace is a decision to prioritize material integrity and process repeatability above all else.

Summary Table:

| Feature | Muffle Furnace | Tube Furnace | Direct-Fired Furnace |

|---|---|---|---|

| Heating Method | Indirect (isolated chamber) | Indirect (tube geometry) | Direct (combustion/elements) |

| Contamination Risk | Very low (shielded sample) | Low (controlled atmosphere) | High (byproducts present) |

| Temperature Uniformity | High (even radiant heat) | High (precise gradients) | Variable (hot spots common) |

| Ideal Applications | Ashing, sintering, high-purity processes | Gas flow processes, custom zones | Bulk industrial heating |

| Processing Type | Batch | Batch/Continuous | Batch/Continuous |

Upgrade your lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met with contamination-free, uniform heating for reliable results. Contact us today to discuss how our furnaces can enhance your material purity and process efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites