At a minimum, operating a muffle furnace requires the use of high-temperature-rated, heat-resistant gloves and protective safety goggles. This foundational gear protects you from the most immediate hazards of severe burns and eye injury. However, a comprehensive safety approach often involves additional protection, such as a face shield and flame-resistant clothing, depending on the specific materials and processes involved.

A muffle furnace's extreme temperatures present multiple, distinct hazards beyond just ambient heat. True safety is not achieved by simply wearing gear, but by understanding the specific risks of your application—from thermal burns to airborne particulates—and matching your protective equipment and procedures accordingly.

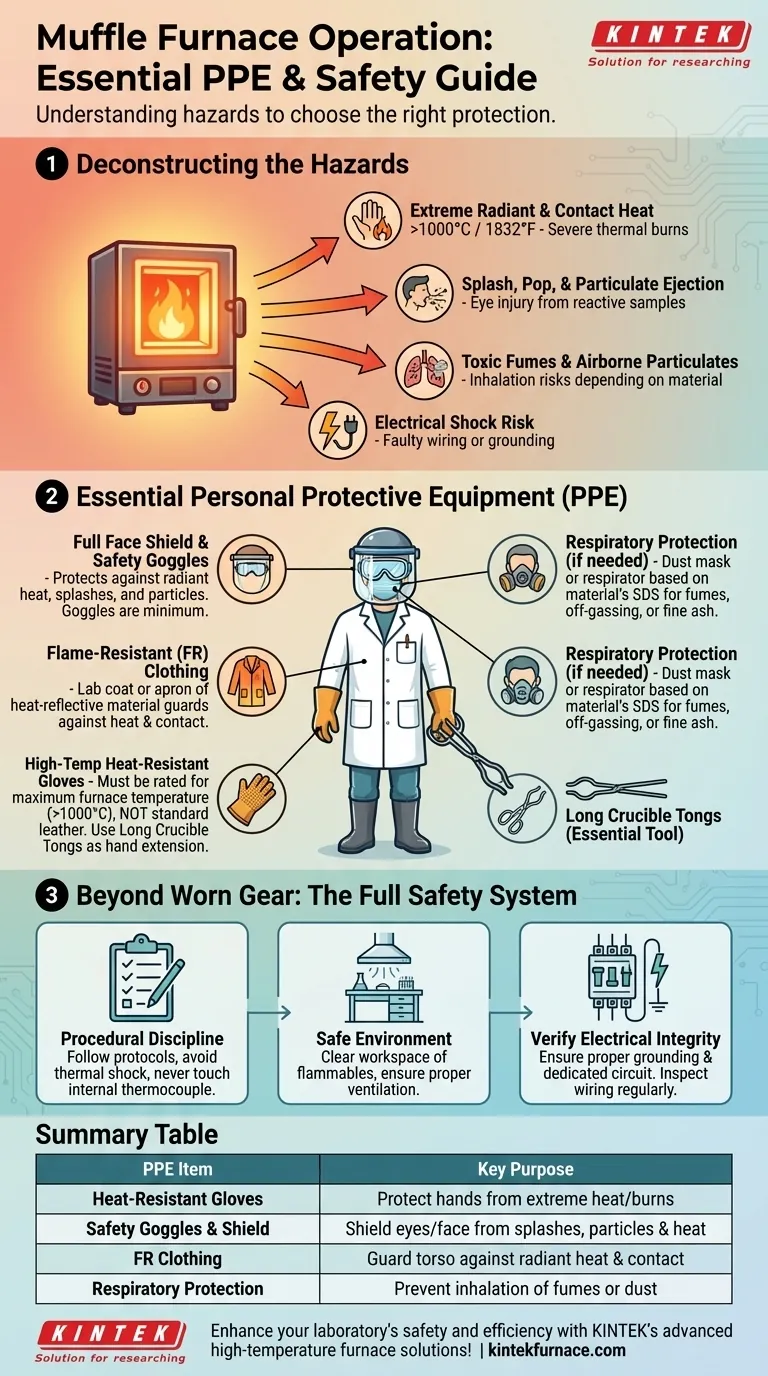

Deconstructing the Hazards: Why Each Piece of PPE Matters

A muffle furnace is more than just a hot box; it's a high-energy environment. Understanding each potential danger is the key to selecting the right protective equipment and, more importantly, using it correctly.

The Primary Hazard: Extreme Radiant and Contact Heat

The most obvious danger is the intense heat, which can exceed 1000°C (1832°F). This heat poses a risk of severe thermal burns from direct contact with the furnace, crucibles, or even through radiant heat when the door is open.

Your primary defenses are:

- Heat-Resistant Gloves: These are non-negotiable. Crucially, your gloves must be rated for the maximum temperature you are working with. Standard leather work gloves are insufficient.

- Flame-Resistant (FR) Clothing: A lab coat or apron made of flame-resistant or heat-reflective material provides a critical barrier for your torso against radiant heat and accidental contact.

- Crucible Tongs: While not "worn" PPE, long, sturdy crucible tongs are an essential extension of your hands, allowing you to handle hot items without exposing yourself to the furnace's interior.

Protecting Your Eyes and Face from Multiple Threats

Your eyes are exceptionally vulnerable to several risks when operating a muffle furnace. The protection you choose should correspond to the specific task you are performing.

- Safety Goggles: This is the absolute minimum. Goggles protect against unexpected splashes or the ejection of small particles if a sample material reacts, pops, or shatters upon heating or cooling.

- Full Face Shield: A face shield should be worn over your safety goggles, especially when loading/unloading the furnace or handling hot crucibles outside of it. It offers a broader layer of protection against intense radiant heat and potential splashes.

Guarding Against Respiratory Risks

The air you breathe can become a hazard depending on what you are heating. The process of ashing, calcination, or heat-treating can release materials into the air.

- Respiratory Protection: The need for a dust mask or respirator is entirely dependent on your sample material. If you are working with fine powders or materials that can produce fumes, toxic off-gassing, or fine ash upon combustion, respiratory protection is essential. Always consult the material's Safety Data Sheet (SDS) to determine the specific respiratory hazards.

Beyond Worn Gear: Understanding the Full Safety System

Personal protective equipment is your last line of defense. A truly safe operation integrates PPE with disciplined procedures and environmental awareness. Ignoring these foundational elements creates risks that no amount of gear can fully mitigate.

The Importance of Procedural Discipline

Your actions are as critical as your equipment. Safe operation is a learned skill that involves constant attention to established protocols.

Key procedures include never touching the internal thermocouple, avoiding thermal shock by cooling the furnace gradually before opening the door, and using crucible tongs for all material handling.

Ensuring a Safe Operating Environment

Your immediate surroundings can either enhance or compromise your safety. The furnace does not exist in a vacuum.

Ensure the area is free of all flammable or explosive materials. A clear, uncluttered workspace minimizes trip hazards when you are carrying extremely hot items.

Verifying Electrical Integrity

A significant, often overlooked, hazard is electrical shock. PPE offers no protection against a major electrical fault.

The furnace must be properly grounded, connected to a dedicated circuit to prevent overloads, and its wiring should be inspected regularly for signs of wear or damage.

Making the Right Choice for Your Goal

Your level of PPE should directly correspond to the risk profile of your specific task. Use this guide to select the appropriate level of protection.

- If your primary focus is basic ashing of stable, non-reactive samples: Heat-resistant gloves and safety goggles, combined with proper tongs, are your essential foundation.

- If you are working with materials that could spatter, pop, or release airborne particles: Add a full face shield for superior protection and evaluate the need for respiratory protection based on the material's properties.

- If you are establishing a comprehensive lab safety protocol: Treat PPE as one component of a system that includes electrical safety checks, disciplined handling procedures, and a safe, uncluttered environment.

Ultimately, effective protection is an active process of ongoing risk assessment, not just a passive checklist of equipment.

Summary Table:

| PPE Item | Purpose | Key Considerations |

|---|---|---|

| Heat-Resistant Gloves | Protect hands from extreme heat and burns | Must be rated for furnace temperatures (e.g., >1000°C) |

| Safety Goggles | Shield eyes from splashes and particles | Wear under a face shield for added protection |

| Flame-Resistant Clothing | Guard torso against radiant heat and contact | Use lab coats or aprons made of FR materials |

| Full Face Shield | Protect face from heat and splashes | Essential during loading/unloading |

| Respiratory Protection | Prevent inhalation of fumes or dust | Required for materials that release airborne hazards |

Enhance your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, helping you achieve superior results while maintaining strict safety standards. Contact us today to discuss how we can support your specific requirements and elevate your operations!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity