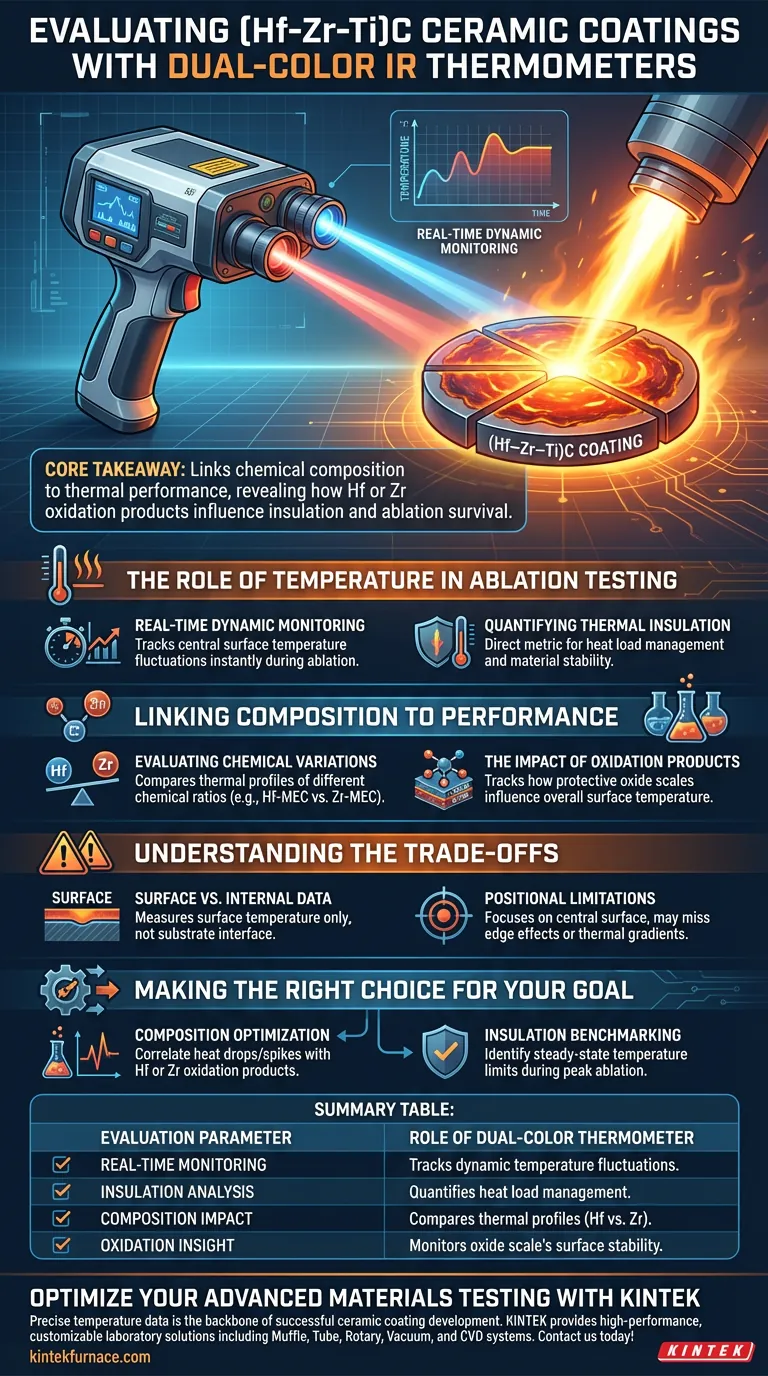

A dual-color infrared thermometer is utilized for the real-time dynamic monitoring of the central surface temperature of (Hf─Zr─Ti)C coatings during high-stress ablation testing. This device provides the critical data needed to quantify the coating's thermal insulation performance and evaluate how the material's surface evolves under extreme heat.

Core Takeaway By continuously tracking surface temperature, the dual-color infrared thermometer serves as the primary tool for linking chemical composition to thermal performance. It reveals how specific oxidation products—generated by elements like Hafnium or Zirconium—directly influence the coating's ability to insulate and survive ablation.

The Role of Temperature in Ablation Testing

Real-Time Dynamic Monitoring

The primary function of the thermometer is to track the central surface temperature of the ceramic coating while it is subjected to ablation.

Rather than providing a single data point, the device offers dynamic monitoring. This allows researchers to observe temperature fluctuations instantly as the test progresses.

Quantifying Thermal Insulation

The temperature data collected serves as a direct metric for thermal insulation performance.

By analyzing the surface temperature, researchers can infer how effectively the coating is managing heat load. A controlled or stabilized surface temperature often indicates effective insulation and material stability.

Linking Composition to Performance

Evaluating Chemical Variations

The thermometer is essential for comparing different chemical compositions, such as Hf-MEC versus Zr-MEC.

It allows researchers to empirically test how replacing specific elements (like substituting Zirconium for Hafnium) alters the thermal profile of the coating.

The Impact of Oxidation Products

The device does not just measure heat; it indirectly monitors chemical reactions.

As the coating oxidizes, it forms specific oxidation products on the surface. The thermometer tracks how these new surface layers affect the overall temperature, providing insight into the protective capabilities of the oxide scale.

Understanding the Trade-offs

Surface vs. Internal Data

It is important to note that this method measures surface temperature only.

While it effectively evaluates the outer defense of the coating, it does not directly measure the temperature at the substrate interface. This requires inference or additional instrumentation.

Positional Limitations

The measurement focuses on the central surface of the sample.

This provides a consistent baseline for comparison but may not capture edge effects or thermal gradients occurring at the periphery of the ablation zone.

Making the Right Choice for Your Goal

To effectively use this data for your materials engineering projects, consider your specific testing objectives:

- If your primary focus is Composition Optimization: Use the temperature data to correlate specific drops or spikes in heat with the presence of Hf or Zr oxidation products.

- If your primary focus is Insulation Benchmarking: Rely on the dynamic monitoring trends to identify the steady-state temperature limits of the coating during peak ablation.

Precise thermometry converts raw heat data into a clear understanding of material longevity and chemical stability.

Summary Table:

| Evaluation Parameter | Role of Dual-Color Thermometer |

|---|---|

| Real-Time Monitoring | Tracks dynamic temperature fluctuations during high-stress ablation. |

| Insulation Analysis | Quantifies how effectively the coating manages extreme heat loads. |

| Composition Impact | Compares thermal profiles between different chemical ratios (e.g., Hf vs. Zr). |

| Oxidation Insight | Monitors how the formation of oxide scales influences surface heat stability. |

Optimize Your Advanced Materials Testing with KINTEK

Precise temperature data is the backbone of successful ceramic coating development. Whether you are benchmarking insulation or optimizing chemical compositions for extreme environments, KINTEK provides the high-performance laboratory solutions you need.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique research requirements. Our systems ensure the thermal stability and precision necessary to validate your most innovative materials.

Ready to elevate your thermal analysis? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Jiachen Li, Hejun Li. Twin Toughening‐Driven Martensitic Transformation Strategy Synergistic Improvement for Plasticity‐Thermal Shock Resistance of (Hf─Zr─Ti)C Ceramic Coating in Severe Thermal Environments. DOI: 10.1002/advs.202503226

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role does a high-alumina ceramic boat play during Ni-Co doped carbon nanotube growth? Key CVD Synthesis Insights

- What core environmental protection does an argon-protected glove box provide for sodium-ion batteries? Maximize Safety

- What are the core functions of high-purity graphite molds and graphite paper in SPS? Optimize Sintering Quality

- What role does a heat-resistant steel retort play in sintering? Mastering Isolation and Pressure for High-Purity Results

- What functions do carbon black and carbon fiber felt serve as insulation? Maximize Efficiency in 3000°C Furnaces

- What key functions do high-strength graphite molds perform? Optimize Al2O3/TiC Hot Press Sintering Success

- Why is a stainless steel closed-end tube required for controlled atmospheric experiments? Ensure Precise Material Purity

- What types of trays are compatible with SiC heating elements? Choose Graphite or Composite Ceramics for Thermal Shock Resistance