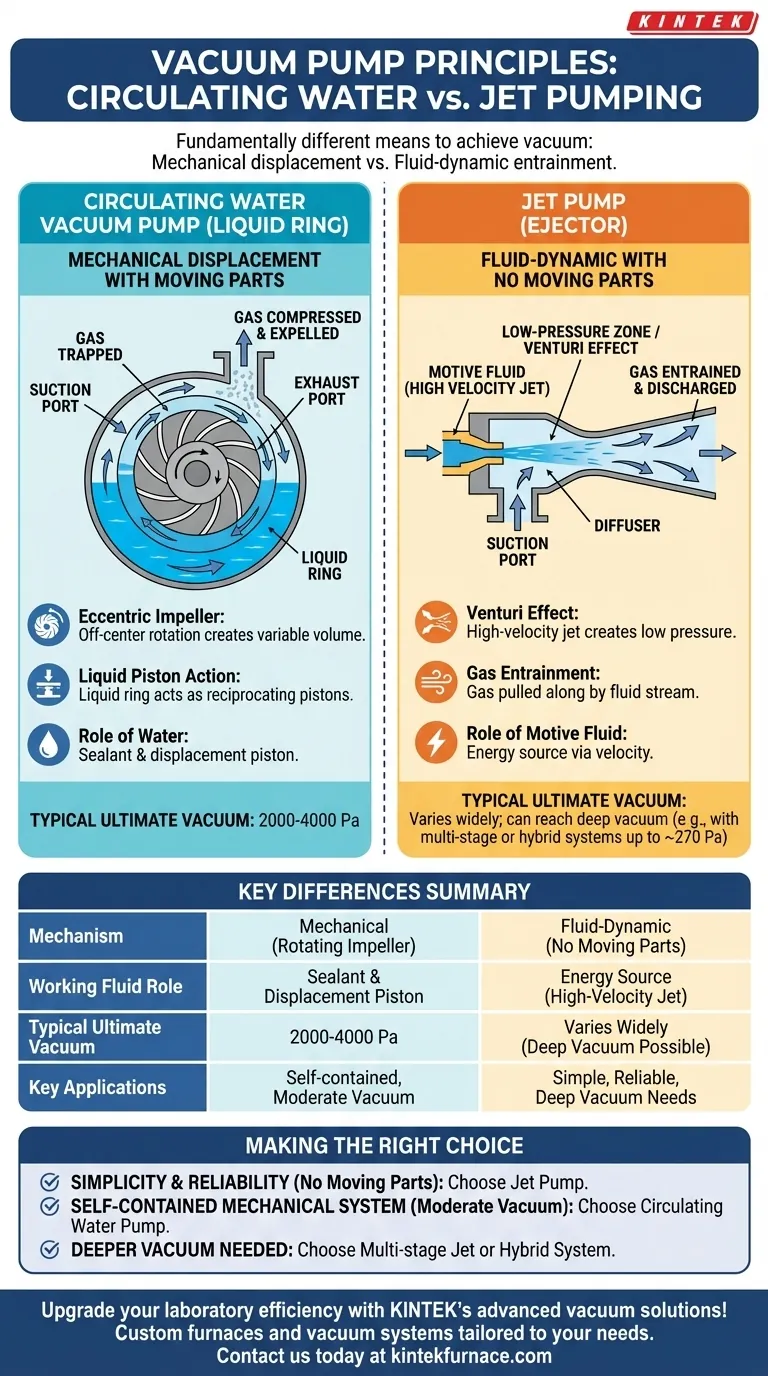

At their core, a circulating water vacuum pump and a jet pump achieve a vacuum through fundamentally different means. The circulating water vacuum pump is a mechanical device that uses a rotating impeller and a liquid ring to physically trap and compress gas, while a jet pump is a fluid-dynamic device with no moving parts that uses a high-velocity fluid stream to create a low-pressure zone that entrains gas.

The crucial distinction lies in the mechanism: a circulating water pump uses moving parts to mechanically displace gas, whereas a jet pump uses the energy of a fluid jet to create a vacuum and pull gas along with it.

The Mechanics of the Circulating Water Vacuum Pump

A circulating water vacuum pump, also known as a liquid ring pump, is a type of positive displacement pump. Its operation relies on a clever mechanical design.

The Role of the Eccentric Impeller

The pump contains an impeller with multiple blades that is installed eccentrically, or off-center, within a cylindrical pump casing.

Forming the Liquid Ring

As the pump is filled with a sealing liquid (typically water) and the impeller rotates, centrifugal force throws the water outward. This forms a stable, concentric ring of liquid that spins along the inner wall of the pump casing.

The 'Liquid Piston' Action

Because the impeller is off-center, the space between the impeller blades and the liquid ring constantly changes. As the blades rotate, the volume of this space increases, drawing gas in from the suction port. As rotation continues, the volume decreases, compressing the trapped gas and expelling it through the exhaust port. This action effectively uses the liquid ring as a series of reciprocating "liquid pistons."

The Principle of the Jet Pump (Ejector)

A jet pump, or ejector, operates on a completely different principle, one based entirely on fluid dynamics and lacking any moving parts.

The High-Velocity Motive Fluid

The pump uses a "motive" fluid, such as high-pressure water or steam, which is accelerated through a nozzle. This converts the fluid's pressure energy into kinetic energy, creating a high-velocity jet.

Creating Negative Pressure

According to the Venturi effect, this high-velocity jet creates an area of extremely low pressure around it. This low-pressure zone is the source of the vacuum.

Gas Entrainment and Pumping

Gas from the system you wish to evacuate is drawn into this low-pressure region. There, it mixes with the high-velocity motive fluid and is carried along with the stream, eventually being discharged at a higher pressure.

Understanding the Key Differences

The operational principles directly influence the characteristics and applications of each pump.

Mechanism: Mechanical vs. Fluid Dynamic

The most fundamental difference is that the circulating water pump is a mechanical device with a rotating impeller. A jet pump has no moving parts, making it exceptionally simple and reliable.

Role of the Working Fluid

In a water ring pump, the water acts as a sealant and a displacement piston. In a jet pump, the motive fluid is the energy source that creates the vacuum through its velocity.

Performance and Application

A standard circulating water vacuum pump can typically achieve an ultimate vacuum of 2000-4000 Pa. In contrast, jet pumps can be designed for a wide range of pressures, and multi-stage jet systems can achieve very deep vacuums. Interestingly, the two technologies can be combined; adding a jet ejector to a water ring pump can significantly improve its ultimate vacuum, reaching levels as low as 270 Pa.

Making the Right Choice for Your Goal

Selecting the correct pump requires understanding how their principles align with your operational needs.

- If your primary focus is simplicity and high reliability with no moving parts: A jet pump is often the superior choice, as it has nothing to wear out or break mechanically.

- If your primary focus is a self-contained mechanical system for moderate vacuum levels: The circulating water vacuum pump provides a robust and effective solution without needing an external high-pressure motive fluid source.

- If your primary focus is achieving a deeper vacuum than a single mechanical pump can provide: A multi-stage jet system or a hybrid approach, such as adding an ejector to a liquid ring pump, is the most effective strategy.

Understanding whether you need a mechanical displacement or a fluid-dynamic entrainment principle is the key to selecting the right tool for your vacuum application.

Summary Table:

| Aspect | Circulating Water Vacuum Pump | Jet Pump |

|---|---|---|

| Mechanism | Mechanical with rotating impeller and liquid ring | Fluid-dynamic with no moving parts |

| Working Fluid Role | Acts as sealant and displacement piston | Acts as energy source via high-velocity jet |

| Typical Ultimate Vacuum | 2000-4000 Pa | Varies widely, can reach deep vacuums with multi-stage systems |

| Key Applications | Self-contained systems for moderate vacuum | Simple, reliable setups requiring no moving parts or deep vacuum |

Upgrade your laboratory efficiency with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your vacuum processes and drive innovation!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- How does a high-precision heating stage contribute to the drying and crystallization of FAPbBr3 nanosheets?

- Why are corundum crucibles selected for high-temperature annealing of LiScO2:Cr3+? Protect Purity and Performance

- Why is a Pt5%Au crucible required for S53P4 bioactive glass? Ensure Purity at 1400°C

- Why is ultrasonic cleaning with acetone required before thermal oxidation? Ensure Perfect Stainless Steel Adhesion

- Why is vacuum sealing in quartz tubes essential for Cr0.82Mn0.18Ge? Ensure Stoichiometry & Purity

- What roles do the high-purity graphite crucible and lid play in PVT AlN growth? Optimize Your Crystal Production

- What are the benefits of the improved circulating water vacuum pump? Save Costs and Go Green in Your Lab

- What key roles do high-purity graphite molds play in SPS? Powering High-Entropy Carbide Synthesis