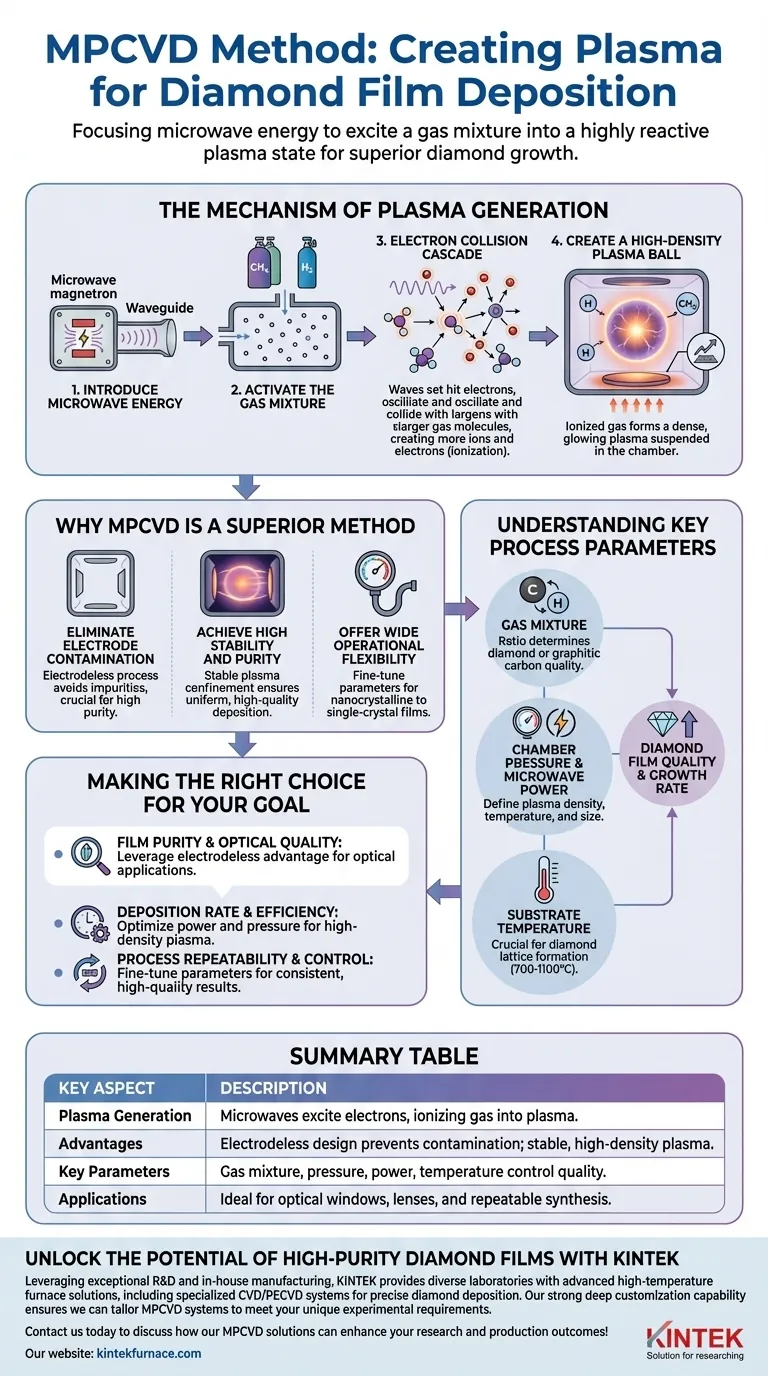

In short, the Microwave Plasma Chemical Vapor Deposition (MPCVD) method uses focused microwave energy to excite a gas mixture into a plasma state. The intense electromagnetic field generated by the microwaves causes free electrons within the gas to oscillate violently, leading to a cascade of collisions that dissociate the source gas molecules (like methane and hydrogen) and create a dense, highly reactive plasma ideal for growing diamond films.

The core principle of MPCVD is not just about creating plasma, but about creating an exceptionally clean, stable, and high-density plasma without direct contact from electrodes. This controlled environment is the key to synthesizing high-purity, high-quality diamond films.

The Mechanism of Plasma Generation

To understand how MPCVD functions, it's best to break the process down into distinct physical steps that occur within the reactor chamber.

Introducing Microwave Energy

An MPCVD system uses a microwave generator, typically a magnetron, to produce high-frequency electromagnetic waves. This energy is channeled through a waveguide and directed into a resonant cavity, which is the main deposition chamber.

Activating the Gas Mixture

A carefully controlled mixture of gases, primarily a small amount of a carbon source (like methane) in a large volume of hydrogen, is fed into the chamber. This gas mixture contains naturally occurring free electrons.

The Electron Collision Cascade

The electromagnetic field from the microwaves transfers energy specifically to these free electrons, causing them to accelerate and oscillate at high speeds. These energized electrons then collide with the much larger and slower gas atoms and molecules.

These collisions are energetic enough to knock more electrons loose from the gas atoms, creating a chain reaction that rapidly increases the number of free electrons and positive ions. This process, known as ionization, is what turns the neutral gas into a plasma.

Creating a High-Density Plasma Ball

The continuous collisions not only ionize the gas but also break apart the source gas molecules. For example, methane (CH₄) and hydrogen (H₂) are dissociated into highly reactive atomic hydrogen (H) and carbon-containing species (like CH₃).

The result is a dense, glowing plasma ball, often with an ionization level above 10%, suspended in the center of the chamber. This plasma is supersaturated with the atomic groups necessary to deposit diamond onto a heated substrate placed within it.

Why MPCVD is a Superior Method for Diamond

The specific way MPCVD generates plasma gives it significant advantages over other deposition techniques, directly impacting the quality of the final diamond film.

Eliminating Electrode Contamination

Unlike other plasma generation methods that use internal electrodes, MPCVD is an "electrodeless" process. This completely avoids the problem of electrode material sputtering and getting incorporated into the diamond film as impurities, which is critical for achieving high purity.

Achieving High Stability and Purity

The plasma generated by MPCVd is exceptionally stable and can be contained away from the chamber walls. This confinement prevents contamination from the reactor itself and ensures a uniform deposition environment, leading to higher-quality films over a larger area.

Offering Wide Operational Flexibility

MPCVD systems can operate effectively over a broad range of pressures. This flexibility allows operators to precisely tune the plasma characteristics to control the growth rate and quality of the diamond, from nanocrystalline to high-quality single-crystal films.

Understanding Key Process Parameters

The success of the deposition relies on precise control over several interconnected variables. The plasma is the engine, but these parameters are the controls.

The Gas Mixture

The ratio of the carbon source gas to hydrogen is a critical factor. It directly influences the type and quality of carbon that forms on the substrate, determining whether you grow high-quality diamond or undesirable graphitic carbon.

Chamber Pressure and Microwave Power

Pressure and microwave power work together to define the plasma's density, temperature, and size. Higher power and pressure generally lead to a denser plasma and a higher deposition rate, but must be carefully balanced to maintain stability.

Substrate Temperature

The temperature of the substrate where the diamond grows is crucial. It must be high enough (typically 700-1100°C) to facilitate the surface chemical reactions that form the diamond lattice but not so high that it promotes the formation of graphite.

Making the Right Choice for Your Goal

Understanding how MPCVD generates its unique plasma allows you to leverage its strengths for specific outcomes.

- If your primary focus is film purity and optical quality: The electrodeless nature of MPCVD is its greatest advantage, as it minimizes contamination and is ideal for applications like optical windows and lenses.

- If your primary focus is deposition rate and efficiency: Focus on optimizing microwave power and gas pressure to create a high-density plasma rich in the necessary atomic species.

- If your primary focus is process repeatability and control: Leverage the inherent stability and wide operational window of MPCVD to fine-tune parameters for consistent, high-quality results across multiple runs.

Ultimately, mastering the MPCVD process comes down to harnessing microwave energy to create a perfectly controlled plasma environment for diamond synthesis.

Summary Table:

| Key Aspect | Description |

|---|---|

| Plasma Generation | Microwaves excite gas electrons, causing collisions that ionize gases like methane and hydrogen into plasma. |

| Advantages | Electrodeless design prevents contamination; stable, high-density plasma ensures purity and uniform deposition. |

| Key Parameters | Gas mixture, chamber pressure, microwave power, and substrate temperature control diamond quality and growth rate. |

| Applications | Ideal for high-purity optical windows, lenses, and efficient, repeatable diamond film synthesis. |

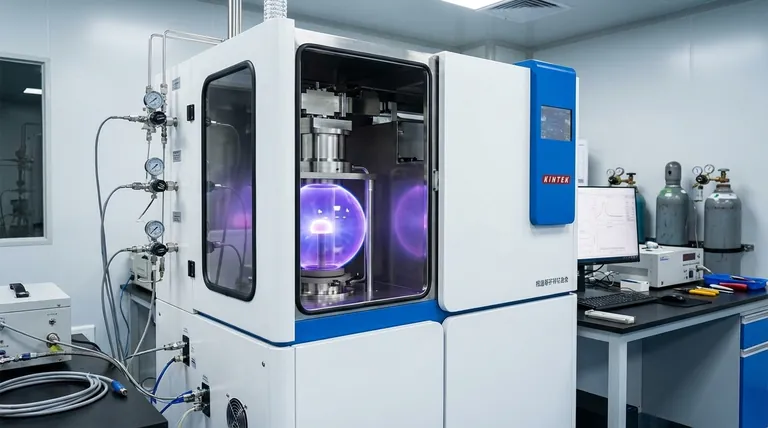

Unlock the Potential of High-Purity Diamond Films with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including specialized CVD/PECVD systems for precise diamond deposition. Our strong deep customization capability ensures we can tailor MPCVD systems to meet your unique experimental requirements, whether you're focused on optical quality, high deposition rates, or process control.

Contact us today to discuss how our MPCVD solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision