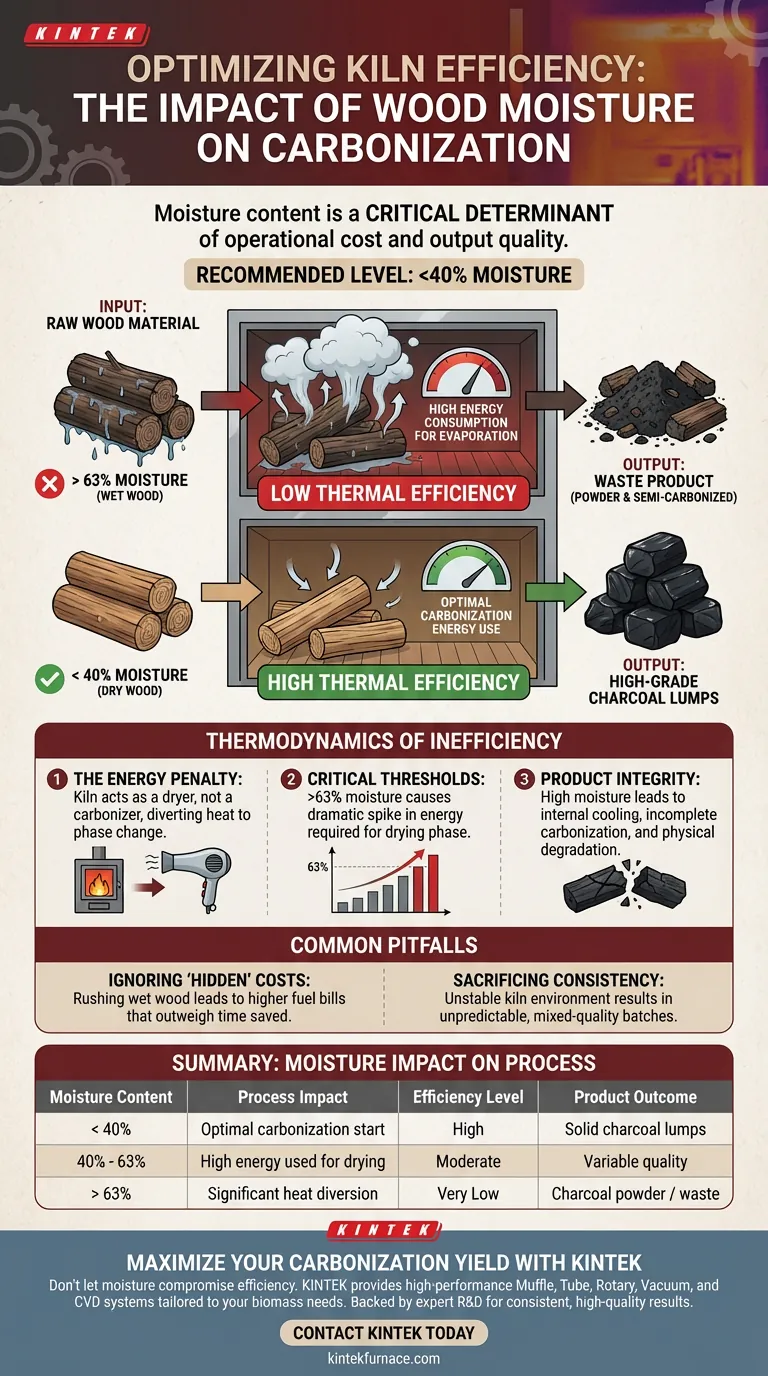

The moisture content of raw wood is a critical determinant of both the operational cost and the output quality of your carbonization kiln. When wood moisture exceeds recommended levels, the kiln must expend significant thermal energy simply to evaporate water before the actual carbonization process can begin, directly reducing the overall efficiency of the system.

To maintain thermal efficiency and product integrity, raw wood moisture should generally be kept below 40%. Processing material with moisture levels above 63% drastically increases energy consumption and frequently results in low-value byproducts.

The Thermodynamics of Carbonization Efficiency

The Energy Penalty of Water

The carbonization process cannot effectively start until the biomass is dry. When you introduce wet wood into the kiln, the system acts as a dryer rather than a carbonizer.

Impact on Thermal Efficiency

High moisture content forces the kiln-furnace system to consume excessive fuel to generate the heat required for evaporation. This diversion of heat lowers the overall thermal efficiency, increasing the time and cost required for each batch.

Critical Moisture Thresholds

Operational data suggests a clear tipping point in efficiency. While levels below 40% are manageable, moisture content exceeding 63% causes a dramatic spike in the energy required for the drying phase.

Consequences for Product Quality

Incomplete Carbonization

Excess moisture creates internal cooling effects that can prevent parts of the batch from reaching the necessary carbonization temperatures. This often results in "semi-carbonized" wood, which is commercially unusable as high-grade charcoal.

Degradation into Waste Product

The struggle to drive off excess water does not just affect the chemistry; it affects the physical structure of the product. High-moisture inputs are significantly more likely to crumble, resulting in a higher percentage of charcoal powder rather than valuable solid lumps.

Common Pitfalls to Avoid

Ignoring the "Hidden" Energy Cost

Operators often underestimate how much energy is lost to phase change (turning water to steam). Attempting to rush wet wood through a kiln invariably leads to higher fuel bills that outweigh the time saved by skipping pre-drying.

Sacrificing Consistency

When moisture levels fluctuate or remain high, the kiln's internal environment becomes unstable. This makes it difficult to predict the quality of the output, leading to batches that are a mix of ash, powder, and unburnt wood.

Making the Right Choice for Your Goal

To optimize your kiln operations, you must treat moisture control as a pre-requisite, not an optional step.

- If your primary focus is maximizing energy efficiency: Strictly dry all raw materials to below 40% moisture to ensure the kiln's heat is used for carbonization rather than evaporation.

- If your primary focus is product quality: Reject raw materials with moisture content near or above 63%, as these will almost certainly yield inferior charcoal powder or semi-carbonized brands.

By rigorously controlling input moisture, you protect both your operating margins and the market value of your final product.

Summary Table:

| Moisture Content | Process Impact | Efficiency Level | Product Outcome |

|---|---|---|---|

| < 40% | Optimal carbonization start | High | Solid charcoal lumps |

| 40% - 63% | High energy used for drying | Moderate | Variable quality |

| > 63% | Significant heat diversion | Very Low | Charcoal powder / semi-carbonized waste |

Maximize Your Carbonization Yield with KINTEK

Don't let moisture compromise your thermal processing efficiency. At KINTEK, we understand that precision is the difference between high-value charcoal and waste byproduct. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces tailored to your unique biomass needs.

Ready to upgrade your lab or industrial carbonization process? Contact KINTEK today to discover how our customizable furnace solutions can deliver the consistent, high-quality results your operations demand.

Visual Guide

References

- Lívia Ferreira Da Silva, Fernando Colen. Kiln-Furnace System: Validation of a Technology for Producing Charcoal with Less Environmental Impact in Brazil. DOI: 10.3390/f15040645

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the two main types of rotary kilns based on heating methods? Choose the Right Kiln for Your Process

- What are the advantages of rotary kiln? Achieve Superior, Continuous High-Temperature Processing

- In which industries are rotary kilns widely used? Essential for Cement, Metals, and Waste Management

- What is the primary function of a rotary kiln in the petroleum coke calcination process? Unlock High-Density Carbon

- What temperature limitations exist for electric kilns? Unlock the Secrets of Kiln Heating Elements

- What role do refractories play in a rotary kiln? Protect, Insulate, and Boost Efficiency

- What is the maximum temperature for a rotary kiln? How to Choose the Right Temperature for Your Process

- What is the purpose of a rotary kiln? Achieve Large-Scale, Uniform Thermal Processing