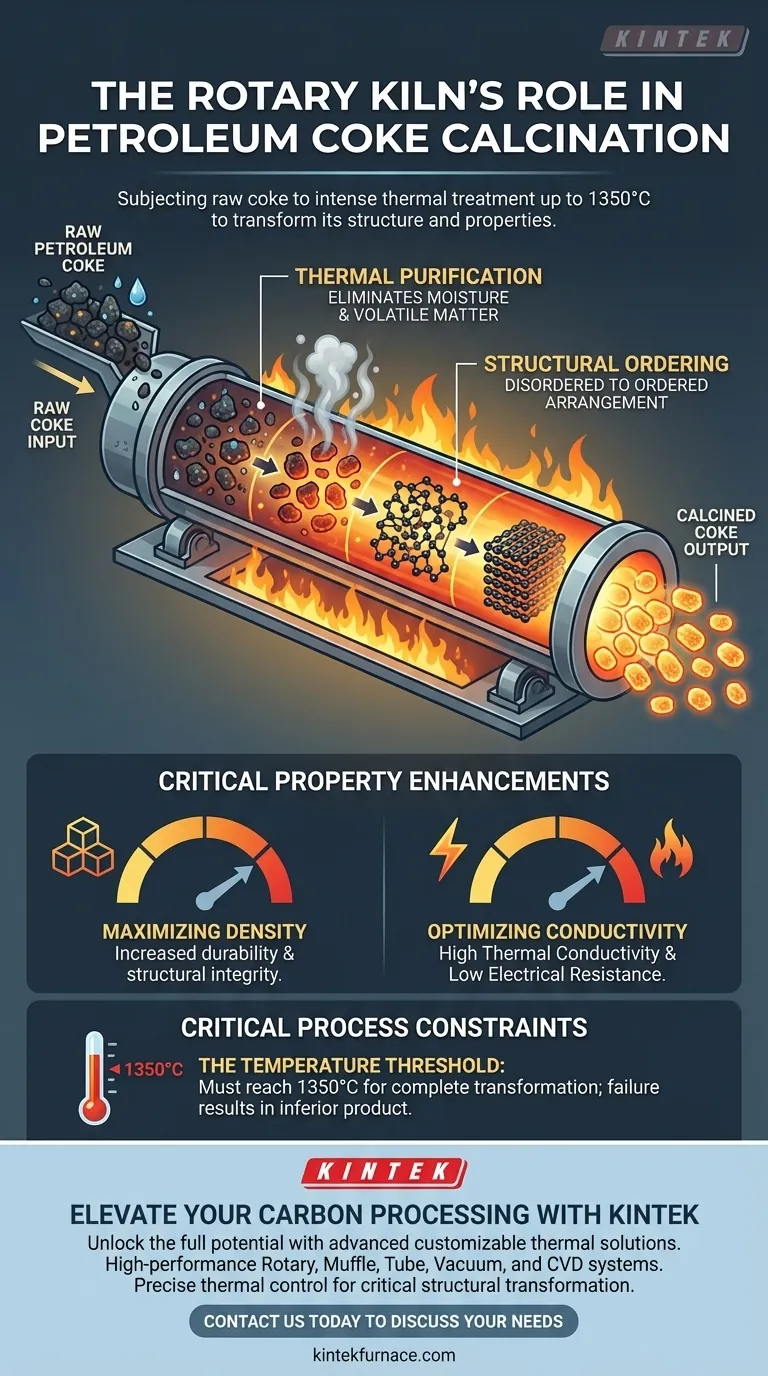

The primary function of a rotary kiln in petroleum coke calcination is to subject raw coke to intense thermal treatment, typically reaching temperatures up to 1350°C. This process serves two immediate purposes: the elimination of moisture and volatile matter, and the fundamental restructuring of the carbon from a disordered state into an ordered arrangement.

The rotary kiln acts as a transformative vessel that does not merely clean the coke, but physically alters its molecular alignment to increase density and conductivity, establishing the necessary foundation for high-quality anisotropic needle coke.

The Mechanics of Structural Transformation

To understand the value of the rotary kiln, one must look beyond simple drying. The kiln drives a complex metamorphic process that changes the material's physical capabilities.

Thermal Purification

The initial role of the kiln is purification. Raw petroleum coke contains significant amounts of moisture and volatile matter that must be expelled.

By applying high-temperature heat treatment, the kiln forces these impurities out of the material. This results in a purer carbon product ready for structural modification.

Ordering the Carbon Lattice

The most critical function of the kiln is the transformation of the carbon structure itself. Raw coke exists in a disordered state.

Through the application of heat up to 1350°C, the kiln forces the carbon atoms to shift into an ordered arrangement. This structural alignment is the prerequisite for producing high-value carbon products.

Critical Property Enhancements

The structural changes induced by the rotary kiln directly correlate to specific performance metrics required for industrial applications.

Maximizing Material Density

As the volatile matter leaves and the structure aligns, the coke becomes significantly denser.

This increase in density is vital for the material's durability and structural integrity in downstream applications.

Optimizing Conductivity

The shift from disordered to ordered carbon has a profound impact on how the material interacts with energy.

The process significantly increases thermal conductivity while simultaneously reducing electrical resistance. This dual enhancement makes the calcined coke highly efficient for thermal and electrical applications.

Critical Process Constraints

While the rotary kiln is effective, the process relies heavily on specific operating conditions to avoid sub-par results.

The Temperature Threshold

The transformation to an ordered state is not gradual; it requires reaching specific high-temperature benchmarks.

Failure to reach the target of 1350°C will result in incomplete calcination. In this scenario, the carbon remains partially disordered, retaining higher electrical resistance and lower density, rendering it unsuitable for high-grade applications.

Making the Right Choice for Your Goal

The rotary kiln is the gateway to specialized carbon applications. Understanding its output helps in defining the quality of your final product.

- If your primary focus is Electrical Efficiency: Ensure the process achieves maximum temperature to fully minimize electrical resistance.

- If your primary focus is Anisotropic Needle Coke: Verify that the calcination has completely shifted the carbon from a disordered to an ordered arrangement to secure the necessary structural foundation.

The rotary kiln turns raw potential into a structured, conductive, and dense reality.

Summary Table:

| Function | Process Detail | Impact on Coke Properties |

|---|---|---|

| Thermal Purification | Removal of moisture and volatile matter | Increases carbon purity and material stability |

| Structural Ordering | Carbon lattice shifts from disordered to ordered | Enhances density and molecular alignment |

| Thermal Optimization | Exposure to temperatures up to 1350°C | Maximizes thermal conductivity |

| Electrical Refinement | Reduction of impurities and structural shift | Lowers electrical resistance for industrial use |

Elevate Your Carbon Processing with KINTEK

Unlock the full potential of your petroleum coke calcination with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Rotary, Muffle, Tube, Vacuum, and CVD systems—all fully customizable to meet your specific temperature and material requirements.

Whether you are aiming for maximum electrical conductivity or the production of high-grade anisotropic needle coke, our systems provide the precise thermal control (up to 1350°C and beyond) necessary for critical structural transformation.

Ready to optimize your lab or production facility? Contact us today to discuss your unique needs with our technical specialists!

Visual Guide

References

- K. A. Krylov, V. M. Dydin. Thermophysical Treatment of Petroleum Coke-Based Electrode Paste as a New Promising Approach to Integrating the Oil Refining and Metallurgical Industries for Carbon-Graphite Electrode Production. DOI: 10.5829/ije.2026.39.02b.05

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the benefits of smoke and ash reduction in electric rotary kilns? Achieve Cleaner, Simpler, and More Cost-Effective Processing

- How do firing times compare between gas and electric kilns? Discover Which Kiln Fits Your Ceramic Art

- What factors should be considered when choosing between gas and electric kilns? Find Your Perfect Fit for Ceramic Art

- What are the primary applications of electric rotary kilns? Precision Thermal Processing for High-Value Materials

- What industries commonly use temperature controllable electric heating rotary furnaces? Essential for High-Purity Material Processing

- What are the temperature zones in an electric heating rotary kiln? Master Precise Thermal Processing

- What are the disadvantages of gas kilns? High Costs, Safety Risks, and Complex Setup

- What are the key highlights of an electric heating rotary kiln compared to fuel-based alternatives? Discover Precision, Savings, and Eco-Friendliness