The primary benefits of eliminating smoke and ash in electric rotary kilns are significant reductions in operational complexity, long-term costs, and environmental impact. By removing fuel combustion from the heating process, these systems bypass the need for expensive exhaust gas treatment and ash disposal, leading to a cleaner, more efficient, and often more economical operation.

The core advantage is not just about being "cleaner." By eliminating smoke and ash, you remove entire subsystems for pollution control and waste handling, which simplifies operations, reduces maintenance, and lowers significant long-term financial burdens.

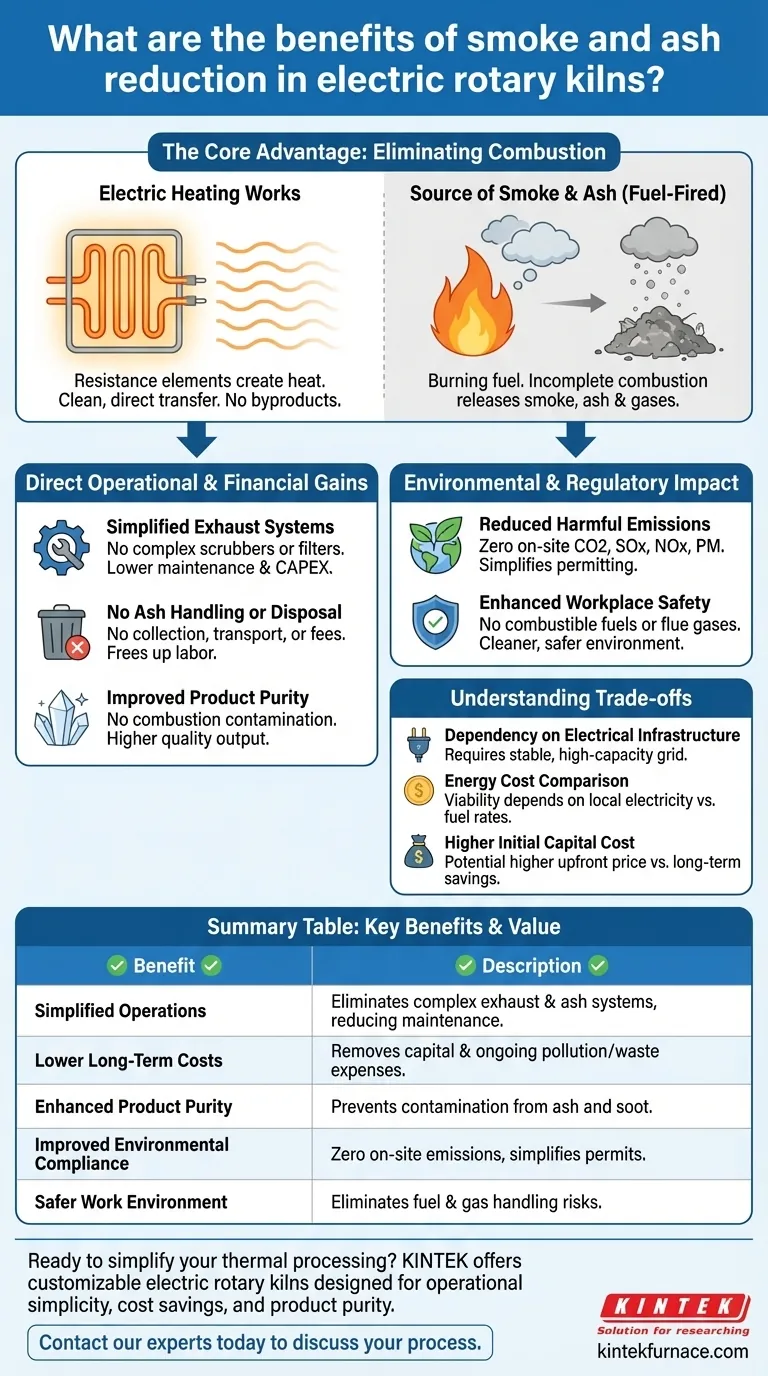

The Core Advantage: Eliminating Combustion

To understand the benefits, it's crucial to recognize the fundamental difference in how electric and fuel-fired kilns generate heat. This distinction is the source of all subsequent advantages.

How Electric Heating Works

Electric rotary kilns use resistance heating elements to generate thermal energy. Heat is transferred directly to the material through radiation and convection, without any chemical reaction or combustion.

This process is inherently clean at the point of use because it does not create byproducts.

The Source of Smoke and Ash

Traditional kilns burn fuel like natural gas, oil, or coal. Smoke is a result of incomplete combustion, releasing particulates and harmful gases.

Ash is the non-combustible residue left over from the fuel source. Both of these byproducts must be managed, treated, and disposed of.

Direct Operational and Financial Benefits

Eliminating combustion byproducts translates directly into tangible operational and financial gains by removing entire stages of the traditional thermal processing workflow.

Simplified Exhaust Systems

Without smoke and flue gases, there is no need for complex and expensive exhaust gas handling systems.

This eliminates the capital and maintenance costs associated with scrubbers, baghouses, filters, and other pollution control equipment required to meet environmental regulations.

No Ash Handling or Disposal

Fuel-fired systems require continuous collection, transportation, and disposal of ash, which incurs significant logistical and financial costs.

Electric kilns completely remove this operational burden, freeing up labor and eliminating disposal fees and associated regulatory compliance.

Improved Product Purity

In many applications, ash and soot can contaminate the material being processed, reducing its quality and value.

Because electric kilns introduce no combustion byproducts into the processing environment, they ensure a higher level of product purity, which is critical in industries like specialty chemicals, ceramics, and food processing.

Understanding the Trade-offs

While the benefits are clear, an objective analysis requires acknowledging the associated trade-offs when considering an electric kiln.

Dependency on Electrical Infrastructure

The primary requirement is access to a stable, high-capacity electrical grid. In remote locations or areas with unreliable power, this can be a significant constraint.

Energy Cost Comparison

The economic viability of an electric kiln is heavily tied to the local cost of electricity versus fossil fuels. While you save on pollution control and disposal, the operational cost hinges on your utility rates.

Higher Initial Capital Cost

Electric rotary kilns can sometimes have a higher upfront purchase price compared to their fuel-fired counterparts. This initial investment must be weighed against the long-term operational savings.

Environmental and Regulatory Impact

The lack of on-site emissions provides a powerful advantage in today's increasingly stringent regulatory landscape.

Reduced Harmful Emissions

Electric kilns produce zero on-site emissions of carbon dioxide, sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter.

This drastically simplifies the environmental permitting process and ensures long-term compliance with air quality standards, avoiding potential fines or mandated shutdowns.

Enhanced Workplace Safety

By eliminating the handling of combustible fuels and the presence of flue gases, electric kilns create a cleaner and safer working environment for operators.

Making the Right Choice for Your Goal

The decision to use an electric rotary kiln should be based on a clear understanding of your primary operational drivers.

- If your primary focus is environmental compliance and ESG goals: An electric kiln is the definitive choice for eliminating on-site emissions and simplifying regulatory adherence.

- If your primary focus is operational simplicity and lower maintenance: The electric kiln wins by removing entire systems for exhaust treatment and ash handling.

- If your primary focus is product purity: An electric system provides an inherently cleaner processing environment, preventing contamination from combustion byproducts.

Ultimately, choosing an electric kiln is a strategic decision to simplify your entire operational ecosystem by design.

Summary Table:

| Benefit | Description |

|---|---|

| Simplified Operations | Eliminates need for complex exhaust gas treatment and ash disposal systems, reducing maintenance. |

| Lower Long-Term Costs | Removes capital and ongoing expenses for pollution control equipment and waste handling. |

| Enhanced Product Purity | Prevents contamination from combustion byproducts like ash and soot. |

| Improved Environmental Compliance | Produces zero on-site emissions, simplifying permits and meeting strict air quality standards. |

| Safer Work Environment | Eliminates risks associated with handling combustible fuels and flue gases. |

Ready to simplify your thermal processing and eliminate the burdens of smoke and ash?

Backed by expert R&D and manufacturing, KINTEK offers a range of customizable electric rotary kilns and other lab high-temperature furnaces (including Muffle, Tube, Vacuum, and CVD systems). Our solutions are designed to deliver the operational simplicity, cost savings, and product purity your application demands.

Contact our experts today to discuss how an electric kiln can transform your process.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems