In short, electric heating rotary kilns offer superior precision, lower long-term operational costs, and a significantly cleaner environmental profile compared to traditional fuel-based alternatives. The core advantages stem from the ability to deliver uniform, easily controlled heat, which directly translates to higher product quality and reduced mechanical stress on the equipment.

The decision between electric and fuel-based kilns is not merely about the energy source. It is a strategic choice between a brute-force heating method and a precision-controlled thermal process that offers compounding benefits in quality, maintenance, and environmental compliance over the life of the asset.

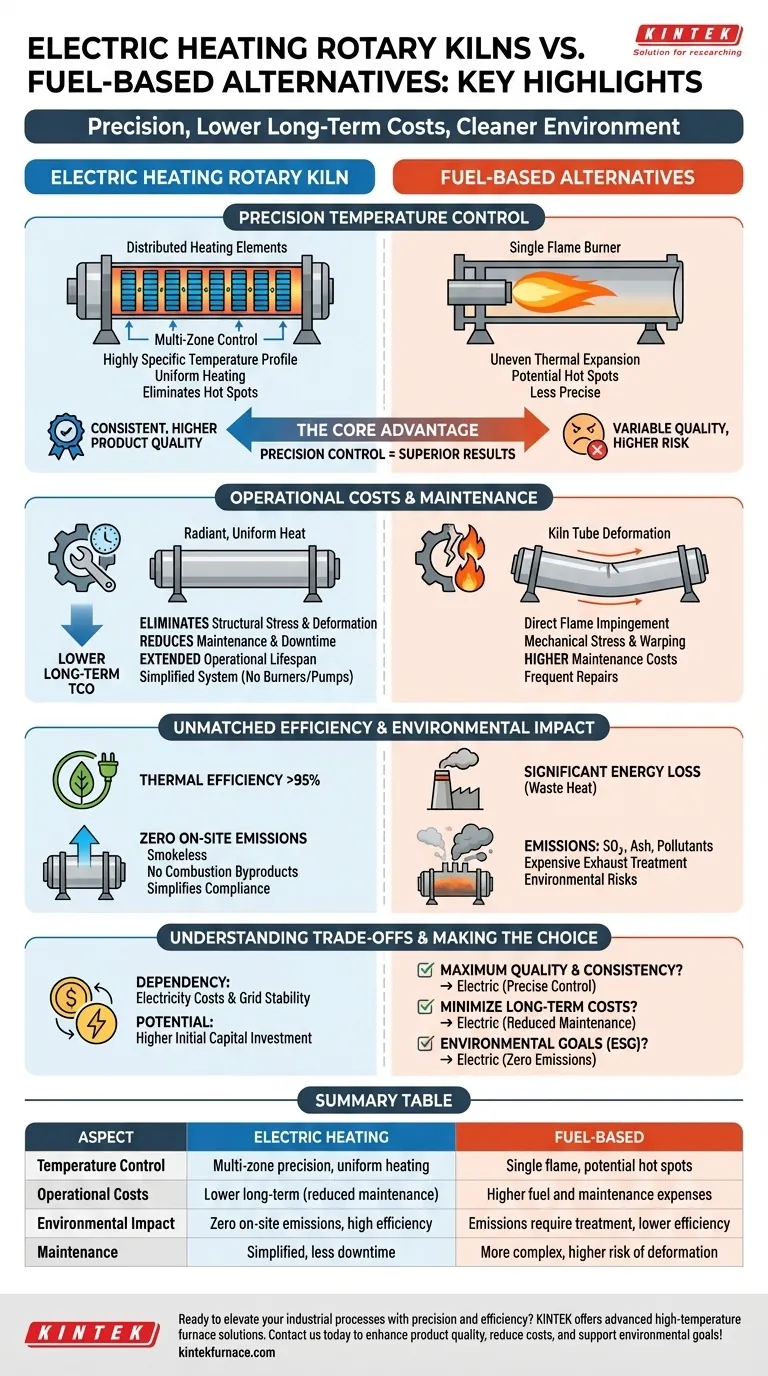

The Core Advantage: Precision Temperature Control

The most significant differentiator of an electric rotary kiln is its ability to precisely manage the thermal environment. This control is the source of most of its other benefits.

How Electric Heating Achieves Precision

Unlike a single, powerful flame from a fuel burner, electric kilns use multiple, distributed heating elements. These are often advanced materials like silicon carbide rods or specialized metal alloys.

These elements can be arranged into separate temperature control zones along the length of the kiln. This allows operators to create a highly specific temperature profile, ensuring the material is heated and cooled at the exact rate required for optimal processing.

The Impact on Product Quality

This granular control directly leads to a more consistent and higher-quality final product. By eliminating the temperature fluctuations and "hot spots" common in fuel-fired kilns, you ensure every batch of material is processed under identical, ideal conditions.

Rethinking Operational Costs and Maintenance

While the initial capital cost can be a factor, the long-term operational and maintenance profile of an electric kiln is often more favorable.

Eliminating Structural Stress and Deformation

Fuel flames create intense, localized heat. This direct flame impingement on the kiln shell causes uneven thermal expansion, leading to mechanical stress, warping, and kiln tube deformation over time.

Electric heating is radiant and uniform, applying energy evenly to the kiln shell. This eliminates the primary cause of structural fatigue and significantly extends the kiln's operational lifespan.

Reducing Maintenance and Downtime

Because there is no risk of flame-induced deformation, the need for costly mechanical realignment and repairs is drastically reduced. Furthermore, the absence of burners, fuel pumps, and complex piping simplifies the entire system, leading to lower maintenance costs and less unscheduled downtime.

Simplifying Logistics and On-Site Safety

Fuel-based systems require extensive logistics, including transportation, delivery scheduling, and large on-site storage tanks. This introduces complexity and safety risks. An electric kiln eliminates the need for fuel storage and logistics, simplifying site management and reducing operational overhead.

Understanding the Trade-offs

No technology is without its considerations. Objectively evaluating an electric kiln requires understanding its potential limitations.

Dependency on Electricity Costs and Stability

The primary operational cost of an electric kiln is electricity. Your budget will be directly tied to the price and volatility of the local energy market. A facility in a region with high electricity costs may find the operational savings are diminished.

Furthermore, the process becomes entirely dependent on the stability of the power grid. Unreliable power can lead to costly production stoppages.

Initial Capital Investment

The sophisticated control systems and specialized heating elements required for an electric kiln can sometimes lead to a higher upfront purchase price compared to a mechanically simpler fuel-fired unit. This initial investment must be weighed against the long-term savings in maintenance and improved product yield.

Unmatched Efficiency and Environmental Impact

For processes where it fits, electric heating offers clear advantages in both energy efficiency and environmental responsibility.

Superior Thermal Efficiency

Electric kilns boast thermal efficiency often exceeding 95%. The energy consumed is converted almost entirely into useful heat within the chamber.

In contrast, fuel-fired kilns lose a significant amount of energy as hot exhaust gases through a flue or chimney. This waste heat represents both an economic loss and an environmental emission.

A Cleaner, Greener Footprint

Electric kilns produce zero on-site emissions. They are inherently smokeless and do not release byproducts like sulfur dioxide (SO₂), ash, or other pollutants associated with combustion. This eliminates the need for expensive exhaust gas treatment systems and simplifies environmental compliance.

Making the Right Choice for Your Process

Your final decision should be guided by your specific operational priorities.

- If your primary focus is maximum product quality and consistency: An electric kiln is the superior choice due to its precise, multi-zone temperature control.

- If your primary focus is minimizing long-term operational costs: An electric kiln's reduced maintenance and extended lifespan often provide a lower total cost of ownership, provided electricity prices are stable.

- If your primary focus is environmental compliance or ESG goals: An electric kiln is the undisputed winner, offering zero on-site emissions and eliminating fuel-related environmental risks.

Ultimately, choosing an electric rotary kiln is an investment in process control and long-term operational stability.

Summary Table:

| Aspect | Electric Heating Rotary Kiln | Fuel-Based Alternatives |

|---|---|---|

| Temperature Control | Multi-zone precision, uniform heating | Single flame, potential hot spots |

| Operational Costs | Lower long-term due to reduced maintenance | Higher fuel and maintenance expenses |

| Environmental Impact | Zero on-site emissions, high efficiency | Emissions require treatment, lower efficiency |

| Maintenance | Simplified, less downtime | More complex, higher risk of deformation |

Ready to elevate your industrial processes with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed for superior performance and durability. With strong deep customization capabilities, we can precisely meet your unique experimental and production requirements. Contact us today to discuss how our electric heating rotary kilns and other solutions can enhance your product quality, reduce costs, and support your environmental goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity