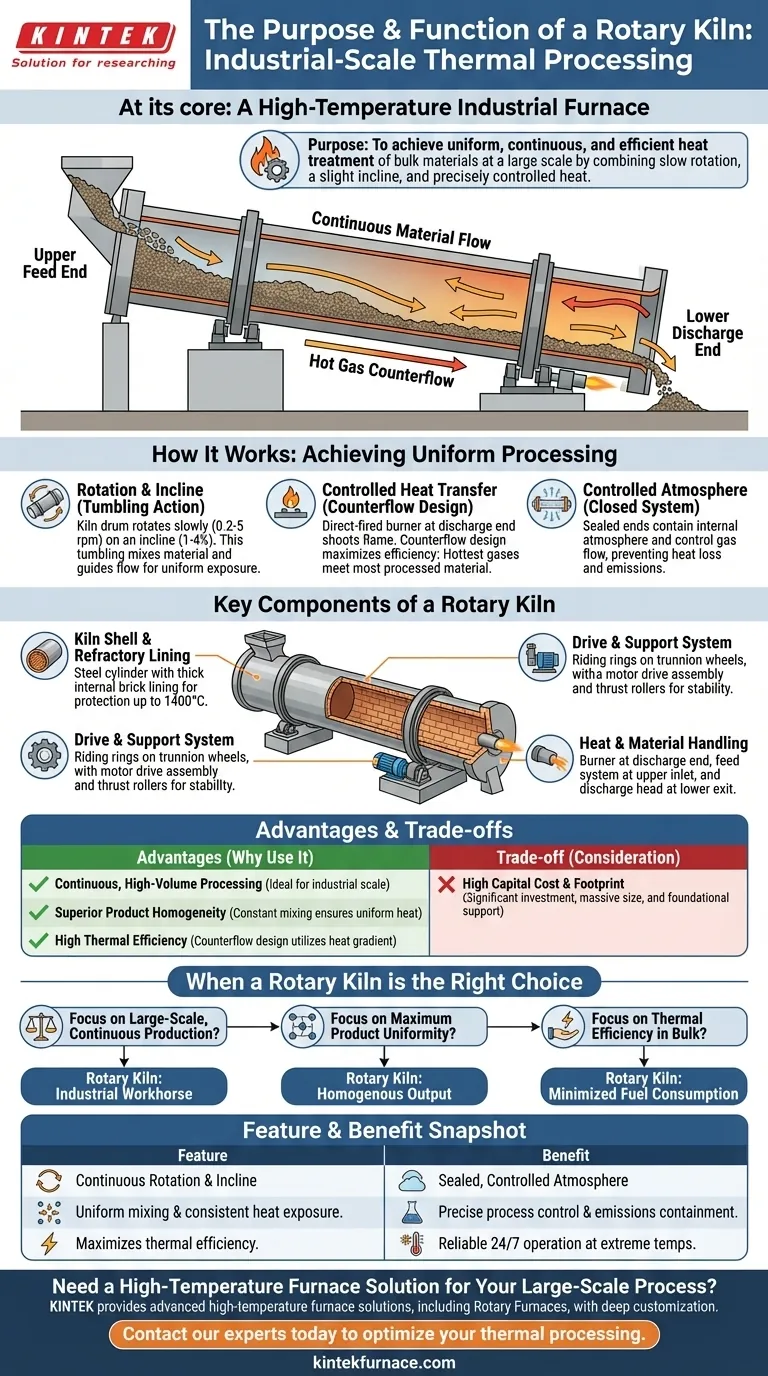

At its core, a rotary kiln is an industrial furnace designed for high-temperature thermal processing. It consists of a long, rotating cylindrical drum, slightly inclined from the horizontal, that tumbles material continuously through a controlled heating environment. This process is used to induce specific chemical reactions or physical changes in raw materials like minerals, ores, or biomass.

The fundamental purpose of a rotary kiln is to achieve uniform, continuous, and efficient heat treatment of bulk materials at a large scale by combining slow rotation, a slight incline, and precisely controlled heat.

How a Rotary Kiln Achieves Uniform Processing

The effectiveness of a rotary kiln lies in its elegant operating principle, which ensures every particle of the material is processed consistently. It accomplishes this through a combination of mechanical movement and optimized heat transfer.

The Principle of Rotation and Inclination

The kiln body, or drum, rotates slowly on its axis, typically between 0.2 and 5 revolutions per minute (rpm). This slow tumbling action constantly mixes the material inside.

Simultaneously, the entire drum is set at a slight incline, usually between 1% and 4%. This slope uses gravity to guide the material from the upper feed end down to the lower discharge end, ensuring a continuous flow.

The combination of rotation and inclination guarantees that the material is constantly turning over, exposing all surfaces to the heat source for a homogenous final product.

The Role of Controlled Heat Transfer

Heat is applied either directly or indirectly. In a direct-fired kiln, a burner located at the discharge end shoots a flame into the drum, allowing hot gases to pass directly over the material.

Most kilns use a counterflow design, where the material moves downhill while the hot gases from the burner move uphill. This is highly efficient, as the hottest gases meet the most processed material, and the coolest gases preheat the new, incoming material.

An indirect-fired kiln heats the material by applying heat to the outside of the kiln shell, which is ideal for processes that cannot tolerate direct contact with combustion gases.

The Importance of a Controlled Atmosphere

Rotary kilns are sealed at both ends. These seals are critical for containing the internal atmosphere and controlling gas flow.

This closed system prevents heat loss, contains dust and emissions, and allows operators to maintain a specific atmosphere (e.g., oxidizing or reducing) required for certain chemical reactions.

Key Components of a Rotary Kiln

The kiln's design is a robust system of interconnected parts, each serving a specific function to ensure reliable, continuous operation.

The Kiln Shell and Refractory Lining

The main body is a heavy-duty steel cylinder known as the kiln shell.

Inside, it is lined with a thick layer of refractory bricks. This insulating layer protects the steel shell from the extreme internal process temperatures, which can exceed 1400°C (2550°F).

The Drive and Support System

The massive weight of the kiln is supported by large steel bands called riding rings, which rest on sets of trunnion wheels.

A powerful drive assembly, consisting of a motor and gearbox, turns a large gear that encircles the kiln shell, providing the slow, powerful rotation. Thrust rollers prevent the kiln from sliding downhill due to its inclination.

The Heat and Material Handling System

The burner is the primary heat source, typically fueled by gas, oil, or coal, and is located at the discharge end.

A feed system continuously introduces raw material into the upper inlet end, while the processed material exits through the discharge head at the lower end.

Understanding the Advantages and Trade-offs

While highly effective, a rotary kiln is a significant piece of industrial equipment with specific strengths and considerations. Its value lies in its scale and consistency.

Advantage: Continuous, High-Volume Processing

Rotary kilns are designed for a constant, uninterrupted flow of material. This makes them ideal for industrial-scale production where stopping and starting is inefficient.

Advantage: Superior Product Homogeneity

The constant tumbling and mixing action is the kiln's greatest strength. It ensures that every particle receives nearly identical heat exposure, leading to a highly uniform and predictable final product.

Advantage: High Thermal Efficiency

The counterflow design of direct-fired kilns is extremely efficient at transferring heat. It minimizes wasted energy by using the full temperature gradient of the combustion gases to dry, preheat, and finally calcine the material.

Trade-off: High Capital Cost and Footprint

Rotary kilns are massive, complex machines that represent a significant capital investment. They require a large physical footprint and substantial foundational support, making them unsuitable for small-scale or pilot projects.

When a Rotary Kiln is the Right Choice

Choosing this technology depends entirely on your processing goals, particularly regarding scale and product consistency.

- If your primary focus is large-scale, continuous production: The rotary kiln is an industrial workhorse built for constant, high-volume throughput.

- If your primary focus is achieving maximum product uniformity: The tumbling action ensures a homogenous output that is difficult to match with static furnaces.

- If your primary focus is thermal efficiency in a bulk process: The counterflow heating principle makes the rotary kiln a highly effective choice for minimizing fuel consumption.

Ultimately, the rotary kiln is a foundational tool in modern industry for transforming raw materials into refined products with precision and efficiency at an immense scale.

Summary Table:

| Feature | Benefit |

|---|---|

| Continuous Rotation & Incline | Ensures uniform mixing and consistent heat exposure for a homogenous product. |

| Counterflow Heating Design | Maximizes thermal efficiency by preheating incoming material with exhaust gases. |

| Sealed, Controlled Atmosphere | Allows for precise process control (oxidizing/reducing) and contains emissions. |

| Robust Construction | Built for reliable, 24/7 operation at extreme temperatures exceeding 1400°C (2550°F). |

Need a High-Temperature Furnace Solution for Your Large-Scale Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse industries with advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique processing requirements.

Let us help you achieve superior product homogeneity and thermal efficiency. Contact our experts today to discuss how a custom furnace solution can optimize your thermal processing.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing