In a rotary kiln, the refractory lining acts as the essential, heat-resistant barrier that makes the entire high-temperature process possible. Its primary roles are to protect the kiln's outer steel shell from melting, insulate the process to maintain extreme temperatures, and minimize heat loss to ensure energy efficiency.

The refractory lining is not merely a passive component; it is the active enabler of the kiln's core function. Without it, the structural steel would fail catastrophically, and the thermal efficiency required for modern industrial processes would be unattainable.

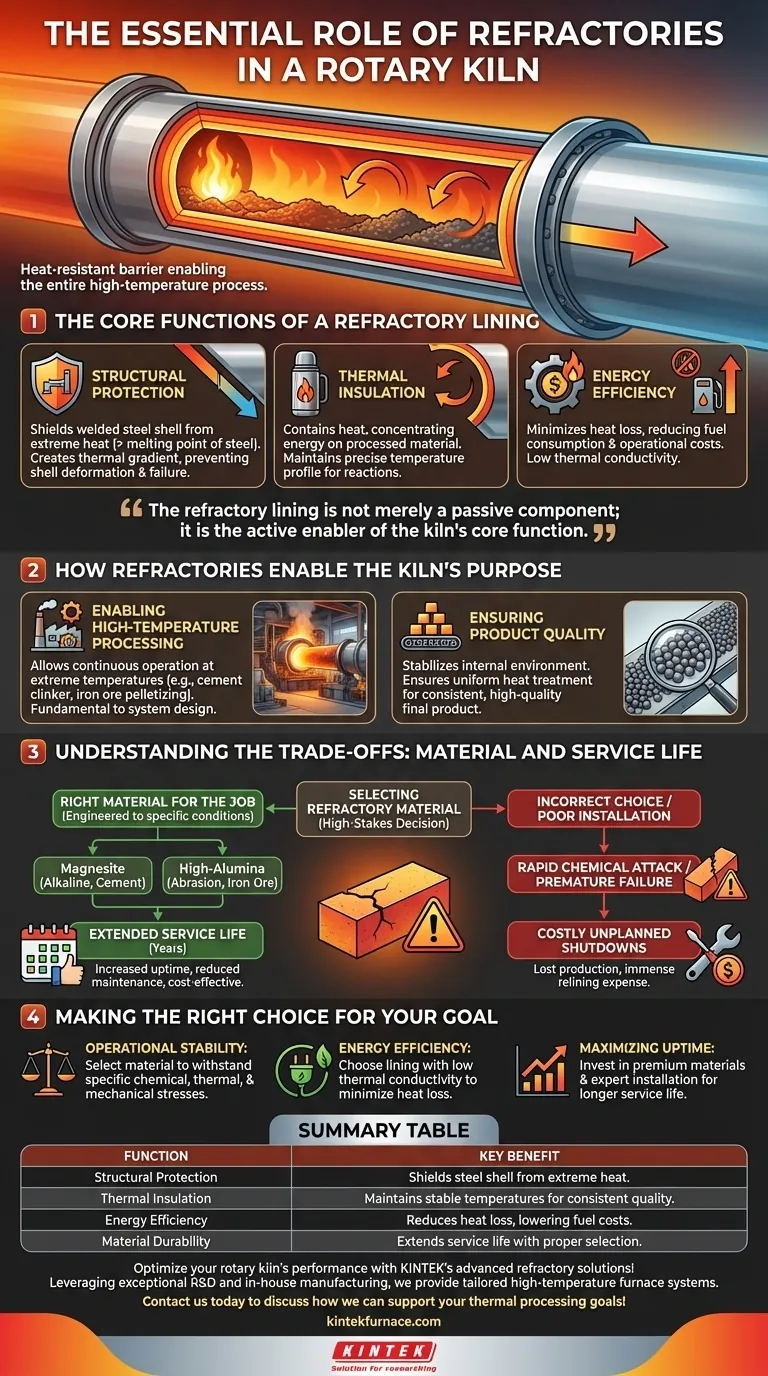

The Core Functions of a Refractory Lining

A rotary kiln's purpose is to process materials at incredibly high temperatures. The refractory lining is the critical interface between this extreme heat and the kiln's mechanical structure.

Structural Protection

The most fundamental role of the refractory is to protect the welded steel shell. The internal operating temperatures of a kiln can far exceed the melting point of steel.

The refractory material creates a thermal gradient, ensuring the temperature at the shell's surface remains within safe structural limits, preventing deformation or complete failure.

Thermal Insulation

By containing the heat, the refractory lining ensures that the thermal energy is concentrated on the material being processed, not escaping into the surrounding environment.

This insulation is vital for maintaining the precise and stable temperature profile required to induce the desired chemical reactions or physical changes in the product.

Energy Efficiency

Minimizing heat loss is directly linked to operational cost. A well-designed refractory lining has low thermal conductivity, acting like the insulation in a thermos.

This reduces the amount of fuel required to maintain the target temperature, making the entire operation more energy-efficient and cost-effective, a key advantage of modern rotary kilns.

How Refractories Enable the Kiln's Purpose

The refractory lining does more than just protect and insulate; it is fundamental to achieving the kiln's primary objective of creating a consistent, high-quality product.

Enabling High-Temperature Processing

The very concept of a rotary kiln—a rotating cylindrical reactor for continuous thermal processing—is predicated on the existence of a durable refractory lining.

It is the component that allows engineers to design systems that operate reliably at the extreme temperatures needed for processes like cement clinker production or iron ore pelletizing.

Ensuring Product Quality

Consistent processing conditions are key to a homogenous final product. The refractory lining helps stabilize the internal environment against fluctuations.

This thermal stability ensures that every particle of material moving through the kiln receives the same uniform heat treatment, which is critical for achieving the specified product quality and consistency.

Understanding the Trade-offs: Material and Service Life

Selecting and installing refractory material is a high-stakes decision involving significant technical trade-offs. The choice directly impacts kiln performance, safety, and operational costs.

The Principle of "Right Material for the Job"

There is no universal refractory solution. The material's composition must be engineered to withstand the specific conditions of the process.

For example, the alkaline environment in a cement kiln requires basic bricks like magnesite, while an iron ore process might use high-alumina bricks to handle its specific chemistry and abrasion. An incorrect choice leads to rapid chemical attack and premature failure.

The Impact on Service Life

The durability of the refractory lining is a primary factor in a kiln's uptime and maintenance budget. A high-quality, correctly installed lining can last for years.

Conversely, a poor material choice or improper lining technique will significantly shorten the service life, leading to costly unplanned shutdowns, lost production, and the immense expense of a complete relining project.

Making the Right Choice for Your Goal

Your operational priorities will guide your refractory strategy. The material selection and lining design must be aligned with your most critical performance indicators.

- If your primary focus is operational stability: The key is selecting a refractory that can withstand the specific chemical, thermal, and mechanical stresses of your material to prevent unexpected failures.

- If your primary focus is energy efficiency: The key is choosing a lining with low thermal conductivity to minimize heat loss through the kiln shell, directly reducing fuel consumption.

- If your primary focus is maximizing uptime: The key is investing in premium refractory materials and expert installation to extend service life and reduce the frequency of shutdowns for relining.

Ultimately, the refractory lining is not just a consumable component; it is the foundation of a reliable and profitable thermal processing operation.

Summary Table:

| Function | Key Benefit |

|---|---|

| Structural Protection | Shields steel shell from extreme heat, preventing deformation and failure |

| Thermal Insulation | Maintains stable temperatures for consistent processing and product quality |

| Energy Efficiency | Reduces heat loss, lowering fuel costs and improving operational economy |

| Material Durability | Extends service life with proper selection (e.g., magnesite for cement kilns) |

Optimize your rotary kiln's performance with KINTEK's advanced refractory solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency, uptime, and cost-effectiveness. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control