Ultimately, an electric kiln's temperature limitation is dictated by the material of its heating elements. Most standard electric kilns use Kanthal (an iron-chromium-aluminum alloy) elements and can safely fire to about Cone 10 (2350°F / 1288°C). Specialized models equipped with silicon carbide (SiC) elements can reach significantly higher temperatures, but this is not the norm.

The crucial takeaway is that while electric kilns are exceptionally versatile, their maximum temperature is a hard limit set by their heating elements. Understanding this limit is essential for matching the kiln to your specific firing requirements, particularly for high-fire applications.

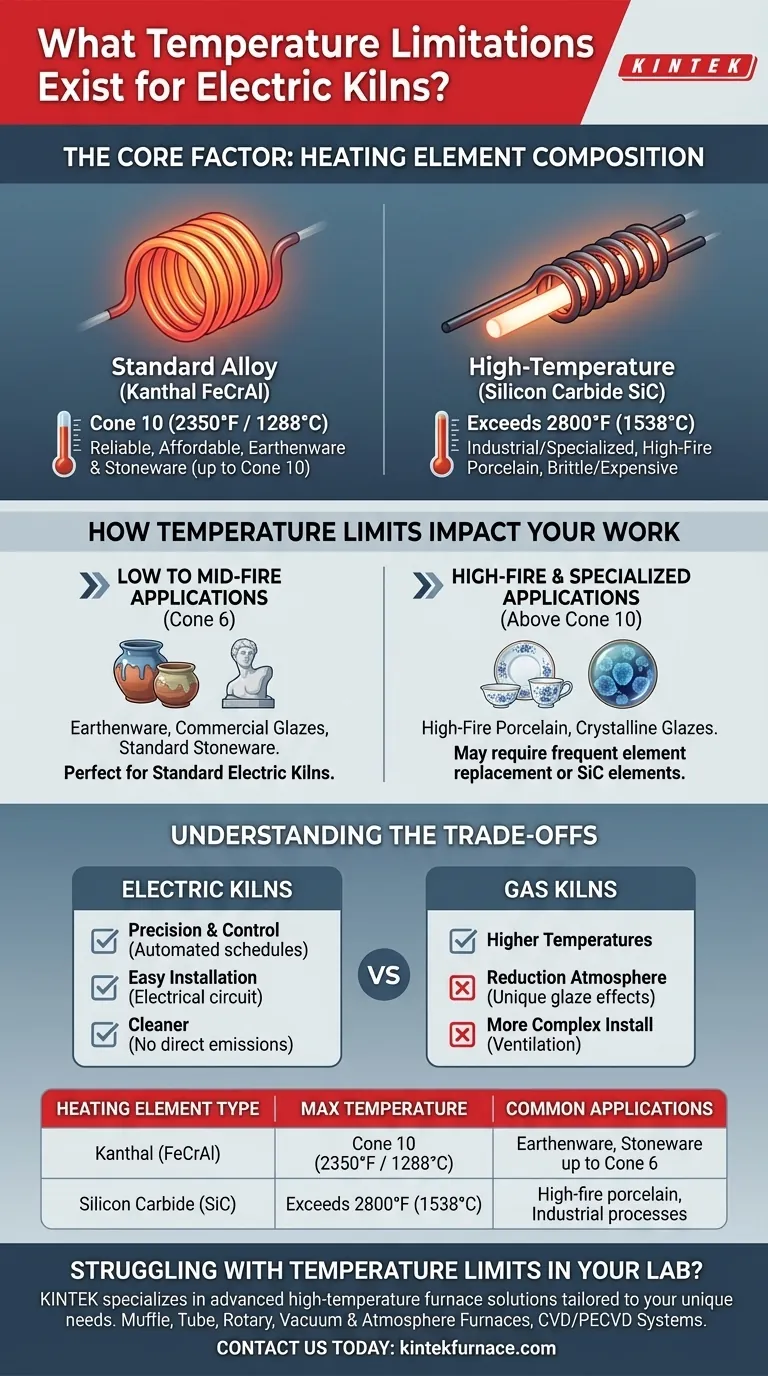

The Core Factor: Heating Element Composition

The heart of an electric kiln is its set of coiled heating elements. The material these elements are made from is the single greatest determinant of the kiln's maximum achievable temperature and its operational lifespan.

Standard Alloy Elements (Kanthal)

Most electric kilns designed for hobbyists, schools, and production studios use heating elements made from a durable alloy, most commonly Kanthal (FeCrAl).

These elements are reliable and relatively affordable. They are engineered to handle the vast majority of ceramic applications, comfortably reaching temperatures for earthenware and most stoneware, up to a practical maximum of Cone 10 (approximately 2350°F or 1288°C).

High-Temperature Elements (Silicon Carbide)

For industrial processes or specialized ceramic work requiring temperatures beyond Cone 10, some electric kilns are built with silicon carbide (SiC) heating elements.

These rods are more brittle and expensive but can operate at much higher temperatures, sometimes exceeding 2800°F (1538°C). These are not typical for standard pottery kilns and are found in more specialized equipment.

How Temperature Limits Impact Your Work

The kiln's temperature ceiling directly affects the types of clay bodies and glazes you can successfully fire.

Low to Mid-Fire Applications

For firing earthenware, most commercial glazes, and standard stoneware (typically Cone 6), a standard electric kiln is perfectly suited. These temperatures fall well within the efficient operating range of Kanthal elements.

High-Fire and Specialized Applications

Firing to Cone 10 is the upper limit for most standard kilns. While possible, consistently firing this high can accelerate the aging process of Kanthal elements, requiring more frequent replacement.

For high-fire porcelain or specific crystalline glazes that require precise control at temperatures above Cone 10, a standard electric kiln may be insufficient.

Understanding the Trade-offs

Choosing a kiln involves balancing temperature needs with other critical factors. While gas kilns often offer a higher temperature ceiling, electric kilns provide distinct advantages.

Temperature vs. Control

Gas kilns can generally reach higher temperatures and are necessary for creating a reduction atmosphere (starving the kiln of oxygen), which produces unique glaze effects.

However, electric kilns offer unparalleled precision and ease of use. Their digital controllers allow for automated, multi-stage firing schedules that are repeatable and highly accurate.

Environment and Installation

Electric kilns are significantly easier to install, requiring only an appropriate electrical circuit. They produce no direct emissions during firing, making them the cleaner and more environmentally friendly option for indoor studio spaces.

Making the Right Choice for Your Goal

Selecting a kiln is about aligning the tool with your artistic or production objectives.

- If your primary focus is on earthenware, sculpture, or standard stoneware (up to Cone 6): A standard electric kiln with alloy elements is the ideal, most efficient choice.

- If your primary focus is on high-fire porcelain or pushing temperatures to Cone 10 consistently: You should budget for more frequent element replacement on a standard kiln or consider a specialized electric model with SiC elements.

- If your primary focus is ease of use, precise automation, and a clean studio: An electric kiln is the superior choice, as long as its temperature range meets your material needs.

By understanding that the heating element defines the temperature limit, you can confidently select an electric kiln that serves as a reliable partner for your work.

Summary Table:

| Heating Element Type | Max Temperature | Common Applications |

|---|---|---|

| Kanthal (FeCrAl) | Cone 10 (2350°F / 1288°C) | Earthenware, stoneware up to Cone 6 |

| Silicon Carbide (SiC) | Exceeds 2800°F (1538°C) | High-fire porcelain, industrial processes |

Struggling with temperature limits in your lab? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to overcome limitations and enhance precision. Whether you're in ceramics, research, or industrial processing, our expertise ensures reliable performance. Contact us today to discuss how we can elevate your high-temperature applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure