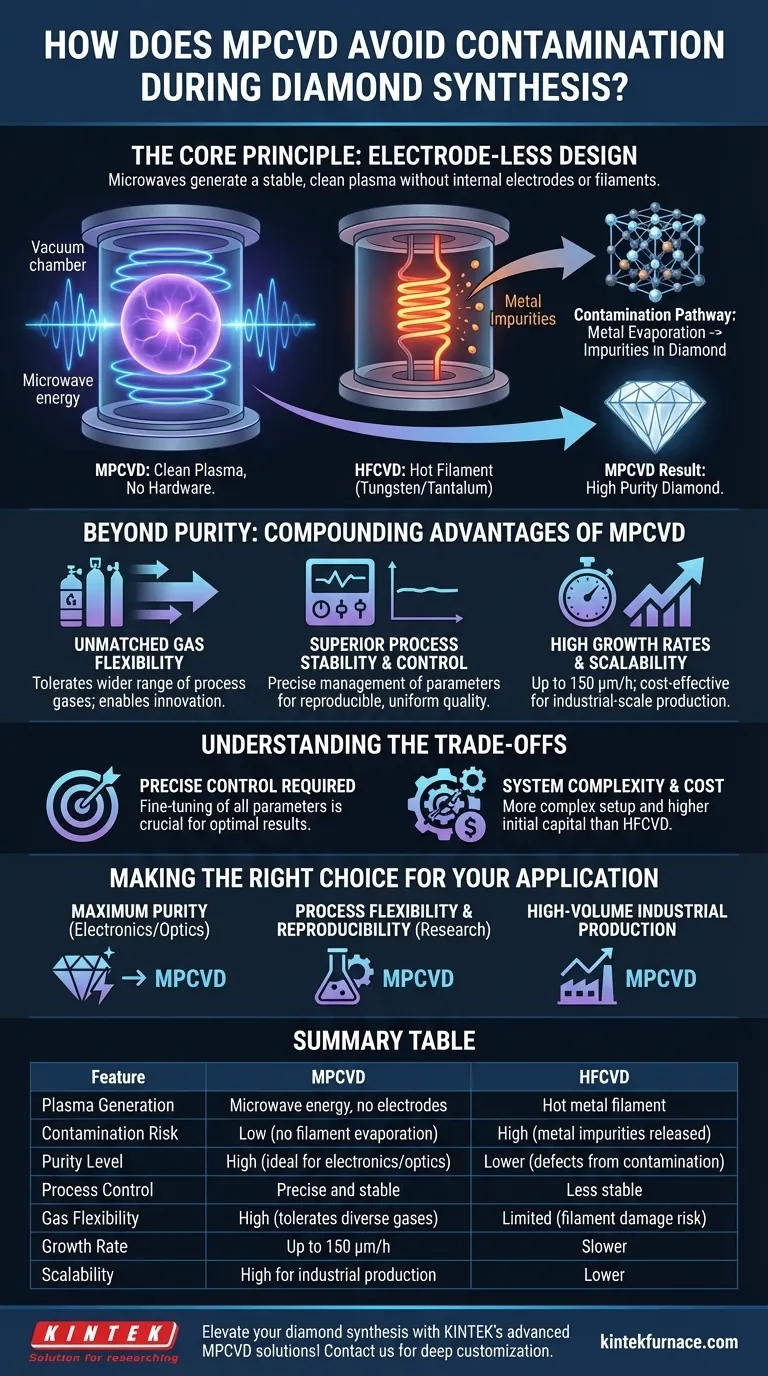

At its core, MPCVD avoids contamination by using microwaves to generate a stable, clean plasma without any internal electrodes or filaments. This electrode-less design is the key difference from other methods, such as Hot Filament CVD (HFCVD), which rely on heated metal wires that degrade and release impurities like tungsten or tantalum directly into the diamond growth environment.

The primary advantage of MPCVD is its fundamental design, which eliminates the main source of contamination found in older methods. This single distinction not only ensures higher purity but also enables a superior level of control over the entire diamond synthesis process.

The Fundamental Difference: How Plasma is Generated

To understand why MPCVD produces purer diamonds, you must first understand how it creates the necessary reactive environment compared to its main alternative, HFCVD.

MPCVD: The Electrode-less Method

In Microwave Plasma Chemical Vapor Deposition (MPCVD), microwave energy is channeled into a vacuum chamber. This energy excites the process gases (typically methane and hydrogen), stripping electrons from the atoms and creating a contained, stable ball of plasma.

Critically, the energy is delivered remotely, with no physical hardware inside the hottest part of the chamber. The plasma is sustained purely by the focused microwave field.

HFCVD: The Hot Filament Method

In contrast, Hot Filament Chemical Vapor Deposition (HFCVD) uses a simpler method. It places a metal wire, or filament (usually made of tungsten or tantalum), inside the chamber.

This filament is heated to extreme temperatures (over 2000°C), causing it to glow white-hot. The process gases break down into reactive species when they come into contact with this intensely hot surface.

The Contamination Pathway

The source of contamination in HFCVD is the filament itself. At such high temperatures, the metal filament begins to evaporate or "sputter," releasing metal atoms into the gas mixture.

These metallic impurities are then incorporated into the growing diamond's crystal lattice, creating defects and reducing its overall quality, particularly for sensitive electronic and optical applications. MPCVD completely sidesteps this problem.

Beyond Purity: The Compounding Advantages of MPCVD

Eliminating the hot filament doesn't just improve purity; it unlocks several other significant advantages that make MPCVD the leading method for high-quality diamond synthesis.

Unmatched Gas Flexibility

Because there is no delicate metal filament to worry about, MPCVD systems can tolerate a much wider range of process gases. Certain gases that would quickly damage or destroy a hot filament in an HFCVD system can be used without issue in an MPCVD reactor. This allows for greater innovation and tailoring of diamond properties.

Superior Process Stability and Control

The plasma generated by microwaves is exceptionally stable and can be precisely controlled. This results in highly reproducible sample quality and uniform diamond growth over a large area. Key parameters like gas mixture, chamber pressure, and substrate temperature can be managed with high precision.

High Growth Rates and Scalability

Modern MPCVD processes can achieve exceptionally high growth rates, with some systems reaching up to 150 μm/h. This is a dramatic improvement over older methods. This combination of speed, stability, and large-area growth makes MPCVD the most promising and cost-effective technique for industrial-scale production.

Understanding the Trade-offs

While superior in many aspects, MPCVD is not without its own set of considerations. The primary challenge lies in its complexity.

The Importance of Precise Control

The power of MPCVD comes from its high degree of process control. However, this also means that achieving optimal results requires precise management of all parameters. The gas mixture, pressure, substrate temperature, and microwave power must all be finely tuned to produce high-quality, uniform diamond films. Any deviation can negatively impact the outcome.

System Complexity

An MPCVD system, with its microwave generator, waveguides, and resonant cavity, is inherently more complex and typically carries a higher initial capital cost than a basic HFCVD setup. This trade-off of complexity for purity and control is a central consideration when evaluating which technology to adopt.

Making the Right Choice for Your Application

Your choice of synthesis method should be dictated by your end goal.

- If your primary focus is maximum purity for electronic or optical quality: MPCVD is the definitive choice, as its filament-free process is the only way to reliably prevent metallic contamination.

- If your primary focus is process flexibility and reproducibility: MPCVD's superior control and compatibility with diverse gas chemistries make it ideal for research and producing consistent, high-quality material.

- If your primary focus is high-volume industrial production: MPCVD's stability, high growth rates, and scalability make it the most viable method for manufacturing large, high-quality single-crystal diamonds.

By fundamentally reimagining how energy is delivered to the system, MPCVD unlocks a level of purity and control that other methods cannot match.

Summary Table:

| Feature | MPCVD | HFCVD |

|---|---|---|

| Plasma Generation | Microwave energy, no electrodes | Hot metal filament |

| Contamination Risk | Low (no filament evaporation) | High (metal impurities released) |

| Purity Level | High (ideal for electronics/optics) | Lower (defects from contamination) |

| Process Control | Precise and stable | Less stable |

| Gas Flexibility | High (tolerates diverse gases) | Limited (filament damage risk) |

| Growth Rate | Up to 150 μm/h | Slower |

| Scalability | High for industrial production | Lower |

Elevate your diamond synthesis with KINTEK's advanced MPCVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored for ultra-pure diamond growth. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our MPCVD technology can enhance your research and production outcomes!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics