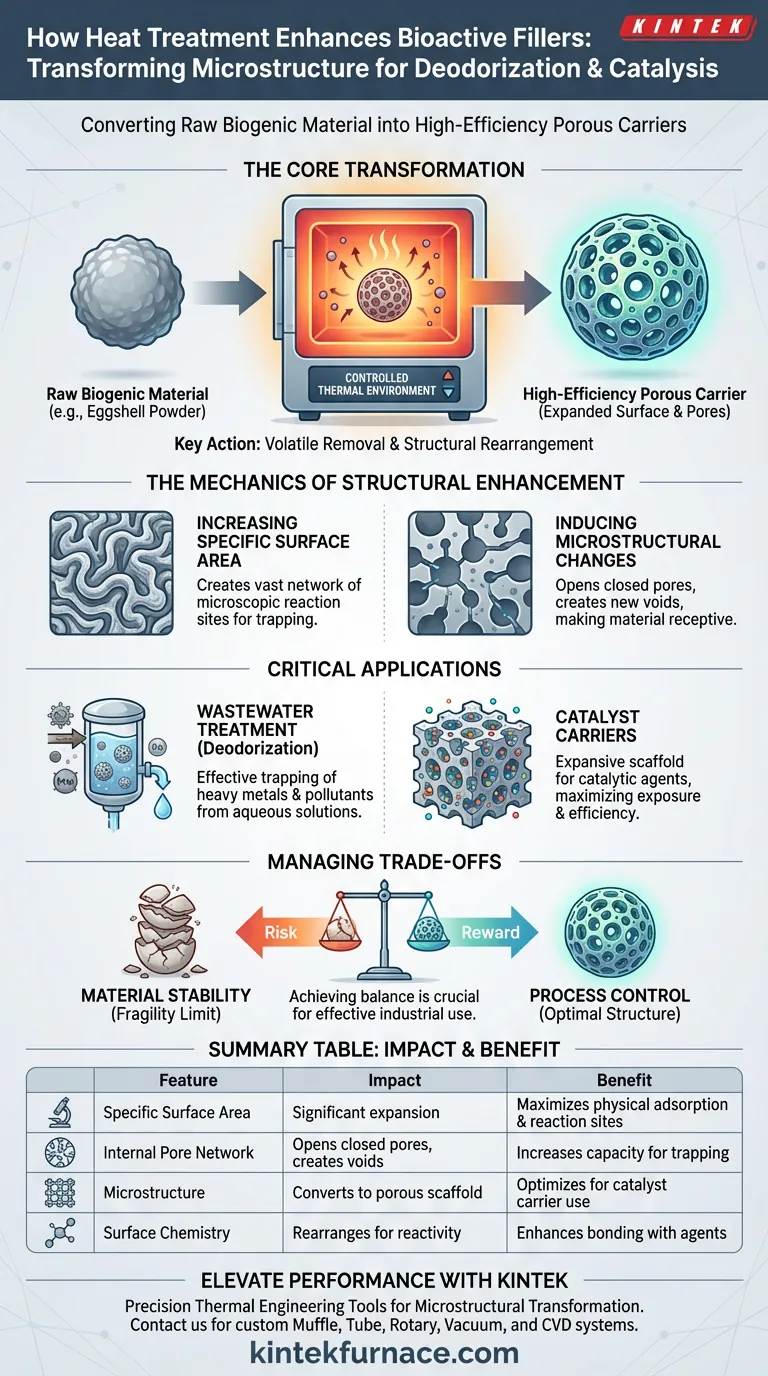

Heat treatment equipment fundamentally transforms the microstructure of bioactive fillers by subjecting them to strictly controlled thermal environments. This process drives physical changes that significantly increase both the specific surface area and total porosity of biogenic particles, such as eggshell powder. By expanding the internal pore network, the equipment directly enhances the material's physical adsorption capacity, making it viable for industrial filtration and catalysis.

Thermal processing is not merely about drying; it is a microstructural engineering tool that converts raw biogenic material into high-efficiency porous carriers suitable for complex filtration and catalytic tasks.

The Mechanics of Structural Enhancement

To understand how bioactive fillers become effective deodorizers or catalyst carriers, you must look at how heat alters the physical architecture of the particle.

Increasing Specific Surface Area

The primary metric for the efficiency of any absorbent material is its specific surface area.

Heat treatment equipment operates to maximize this area by removing volatile components and rearranging the internal structure of the material.

This creates a vast network of microscopic surfaces where chemical reactions or physical trapping can occur.

Inducing Microstructural Changes

The equipment utilizes controlled atmospheres to induce stress and structural shifts within the biogenic particles.

These shifts open up closed pores and create new voids within the material matrix.

The result is a material that is no longer dense and impermeable, but rather highly porous and receptive to external fluids and gases.

Critical Applications for Porous Fillers

Once the porosity is enhanced, the material transitions from simple waste (like eggshell powder) to a functional industrial tool.

Wastewater and Heavy Metal Treatment

Enhanced porosity is the key driver for effective wastewater remediation.

The expanded pore structure allows the filler to physically adsorb heavy metals and other contaminants from aqueous solutions.

Without the microstructural changes induced by heat treatment, the material would lack the capacity to trap these pollutants effectively.

Serving as Catalyst Carriers

In catalytic applications, the bioactive filler acts as a support structure rather than the active agent.

The increased specific surface area provides an expansive scaffold where catalytic agents can be deposited.

This maximizes the exposure of the catalyst to the reaction medium, significantly improving overall process efficiency.

Understanding the Trade-offs

While heat treatment is essential for activating these materials, it introduces specific constraints that must be managed.

Process Control Sensitivity

Achieving the optimal pore structure requires precise control over the thermal atmosphere.

Inconsistent temperature or atmospheric conditions can lead to uneven porosity, rendering parts of the batch ineffective.

Material Stability

There is a physical limit to how much porosity can be induced before the material compromises its structural integrity.

Pushing the specific surface area too high through aggressive heating may result in particles that are too fragile for rigorous industrial flows.

Making the Right Choice for Your Goal

The level of heat treatment required depends heavily on your specific end-use application.

- If your primary focus is Wastewater Treatment: Prioritize treatment protocols that maximize total pore volume to ensure the highest possible capacity for trapping heavy metals.

- If your primary focus is Catalytic Support: Focus on achieving a balance between high surface area and mechanical stability to ensure the carrier remains intact during chemical reactions.

By precisely controlling thermal processing, you turn biogenic limitations into high-performance porous advantages.

Summary Table:

| Feature | Impact of Heat Treatment | Benefit for Application |

|---|---|---|

| Specific Surface Area | Significant expansion through volatile removal | Maximizes physical adsorption & reaction sites |

| Internal Pore Network | Opens closed pores and creates new voids | Increases capacity for heavy metal & pollutant trapping |

| Microstructure | Converts dense particles into porous scaffolds | Optimizes material for use as high-efficiency catalyst carriers |

| Surface Chemistry | Rearranges biogenic matrix for better reactivity | Enhances bonding with active catalytic agents |

Elevate Your Material Performance with KINTEK

Are you looking to transform biogenic materials into high-efficiency industrial fillers? KINTEK provides the precision thermal engineering tools necessary to master microstructural transformation. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific porosity and surface area requirements.

Whether you are developing advanced wastewater filtration media or stable catalyst supports, our high-temperature lab furnaces ensure the consistent atmospheric control your research demands. Contact KINTEK today to discuss your unique needs and discover how our equipment can drive your next breakthrough in material science.

Visual Guide

References

- Sara Piras, Carlo Santulli. Biomimetic Use of Food-Waste Sources of Calcium Carbonate and Phosphate for Sustainable Materials—A Review. DOI: 10.3390/ma17040843

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How do high-precision electric furnaces facilitate microstructural transformation in aluminum alloys? Expert Insights

- What is a muffle furnace and how does it work? Discover Its Key Benefits for Your Lab

- What are the different types of muffle furnaces and their features? Choose the Right One for Your Lab

- What core function does a muffle furnace serve in superconducting material synthesis? Master Solid-State Reactions

- How is a muffle furnace utilized in the post-processing of hydroxyapatite (HA) powder? Optimize Purity and Bioactivity

- How is temperature uniformity achieved in a muffle furnace? Ensure Consistent Heat for Reliable Results

- What safety measures should be followed when using a muffle furnace? Essential Steps for Safe Operation

- What is the significance of using a muffle furnace for Y2O3 coated MgO: Ce3+? Optimize Particle Crystallization