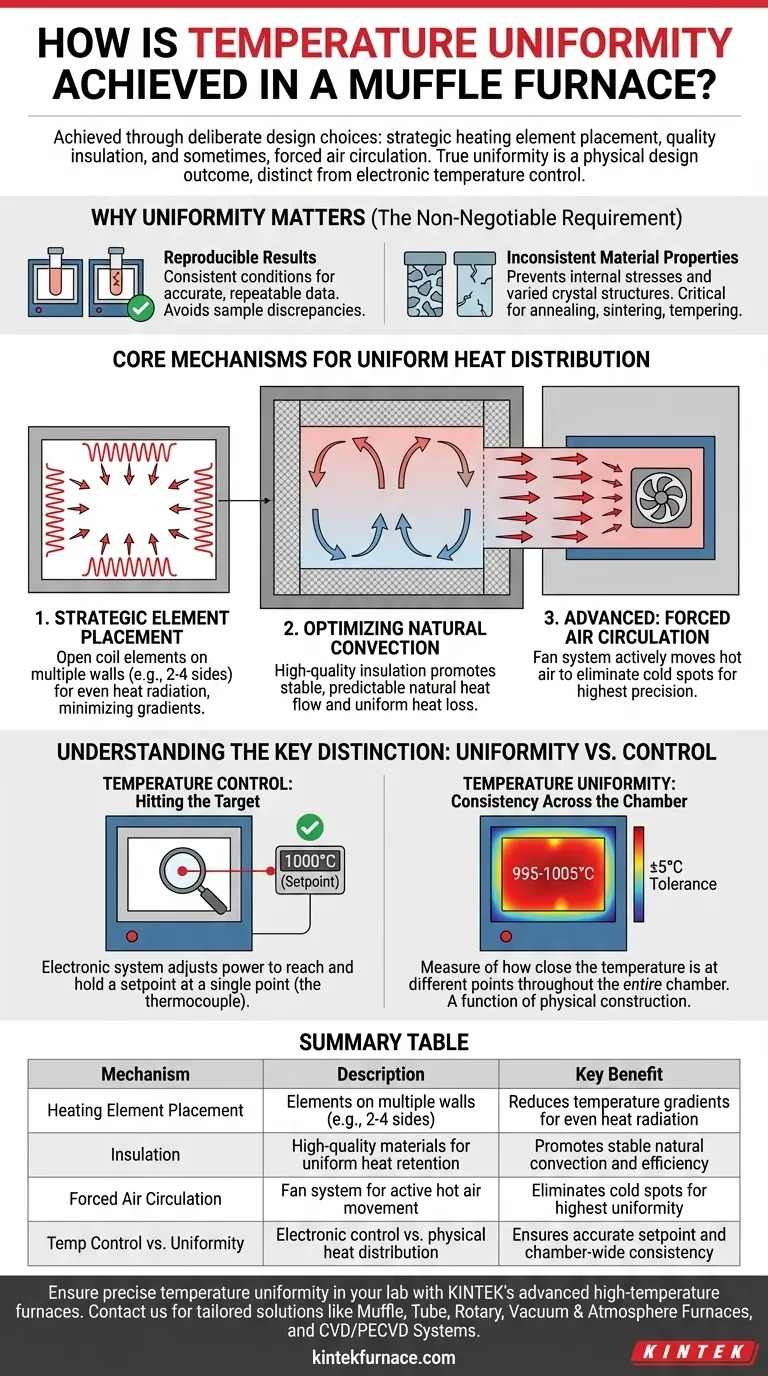

In short, temperature uniformity in a muffle furnace is achieved through a combination of deliberate design choices. These include the strategic placement of heating elements on multiple sides of the chamber, insulation that promotes even heat distribution, and in some advanced models, forced air circulation systems that actively move hot air to eliminate cold spots.

The core challenge isn't just reaching a high temperature, but ensuring that temperature is consistent throughout the entire usable chamber. True uniformity is the result of a furnace’s physical design—how it generates and distributes heat—which is a separate and distinct concept from its electronic temperature control system.

Why Temperature Uniformity is a Non-Negotiable Requirement

For any process involving thermal treatment, uneven heating is a direct cause of failed experiments and inconsistent product quality. Understanding why uniformity is critical is the first step to ensuring reliable outcomes.

The Goal: Reproducible Results

The fundamental principle of scientific and industrial testing is reproducibility. If a sample on the left side of the furnace is exposed to 900°C while a sample on the right sees 870°C, they have not undergone the same process.

This discrepancy makes it impossible to achieve accurate and repeatable results, invalidating the data.

The Risk: Inconsistent Material Properties

For processes like annealing, sintering, or tempering, slight variations in temperature can drastically alter a material's final properties.

Inconsistent heating leads to parts with internal stresses, varied crystal structures, or incomplete chemical reactions. This is unacceptable in both research and manufacturing, where material integrity is paramount.

Core Mechanisms for Achieving Uniform Heat Distribution

Manufacturers employ several key strategies to ensure heat is distributed as evenly as possible. These mechanisms work together to create a stable thermal environment.

Strategic Placement of Heating Elements

The most common method for promoting uniformity is placing open coil heating elements on multiple interior walls of the furnace chamber.

By positioning elements on two, three, or even four sides, heat radiates inward from multiple directions. This minimizes the temperature gradient that would occur if heat originated from only one location, such as the back wall.

Optimizing Natural Convection

The very shape and construction of the furnace chamber are designed to manage heat flow. High-quality insulation not only retains heat for efficiency but also ensures that heat loss is uniform across all surfaces.

This stable environment allows for a predictable natural convection pattern, where hot air rises and cooler air sinks, circulating heat throughout the chamber without any mechanical assistance.

Advanced Design: Forced Air Circulation

For applications demanding the highest level of precision, some furnaces incorporate a hot air circulation system.

These models use a fan, typically located in a separate chamber, to actively blow pre-heated air throughout the furnace. This forced convection is the most effective method for eliminating hot and cold spots, delivering exceptional temperature uniformity.

Understanding the Key Distinction: Uniformity vs. Control

It is critical to distinguish between the furnace's ability to maintain a setpoint and its ability to distribute that heat evenly.

Temperature Control: Hitting the Target

Temperature control is the job of the electronic system. A thermocouple measures the temperature at a single point inside the chamber and sends feedback to a digital controller.

The controller then adjusts power to the heating elements to reach and hold a specific setpoint (e.g., 1000°C). This ensures the temperature at the thermocouple's location is accurate.

Temperature Uniformity: Consistency Across the Chamber

Temperature uniformity is a measure of how close the temperature is at different points throughout the entire chamber. A furnace can have perfect control at 1000°C at one point but have cold spots of 950°C in the corners.

Uniformity is a function of the furnace’s physical construction—element placement, insulation, and air circulation. It is typically specified by the manufacturer as a tolerance, such as ±5°C at a given temperature.

Making the Right Choice for Your Application

Selecting a furnace requires matching its uniformity capabilities to your process needs.

- If your primary focus is basic ashing or heat treatment where high precision is not critical: A standard furnace with heating elements on two sides and good insulation is often sufficient.

- If your primary focus is research, quality control, or sensitive processes like annealing and sintering: Prioritize a furnace with heating elements on at least three sides or one that includes a forced air circulation system.

- If your primary focus is process validation and certification: You must obtain the manufacturer's official temperature uniformity specification (e.g., ±°C) and ensure it meets the strict requirements of your protocol.

Understanding these design principles empowers you to look beyond the maximum temperature and choose the right tool to guarantee the integrity of your results.

Summary Table:

| Mechanism | Description | Key Benefit |

|---|---|---|

| Heating Element Placement | Elements on multiple walls (e.g., 2-4 sides) | Reduces temperature gradients for even heat radiation |

| Insulation | High-quality materials for uniform heat retention | Promotes stable natural convection and efficiency |

| Forced Air Circulation | Fan system for active hot air movement | Eliminates cold spots for highest uniformity |

| Temperature Control vs. Uniformity | Electronic control vs. physical heat distribution | Ensures accurate setpoint and chamber-wide consistency |

Ensure precise temperature uniformity in your lab with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs for reliable annealing, sintering, and more. Contact us today to discuss how we can enhance your thermal processes and deliver consistent, high-quality results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity