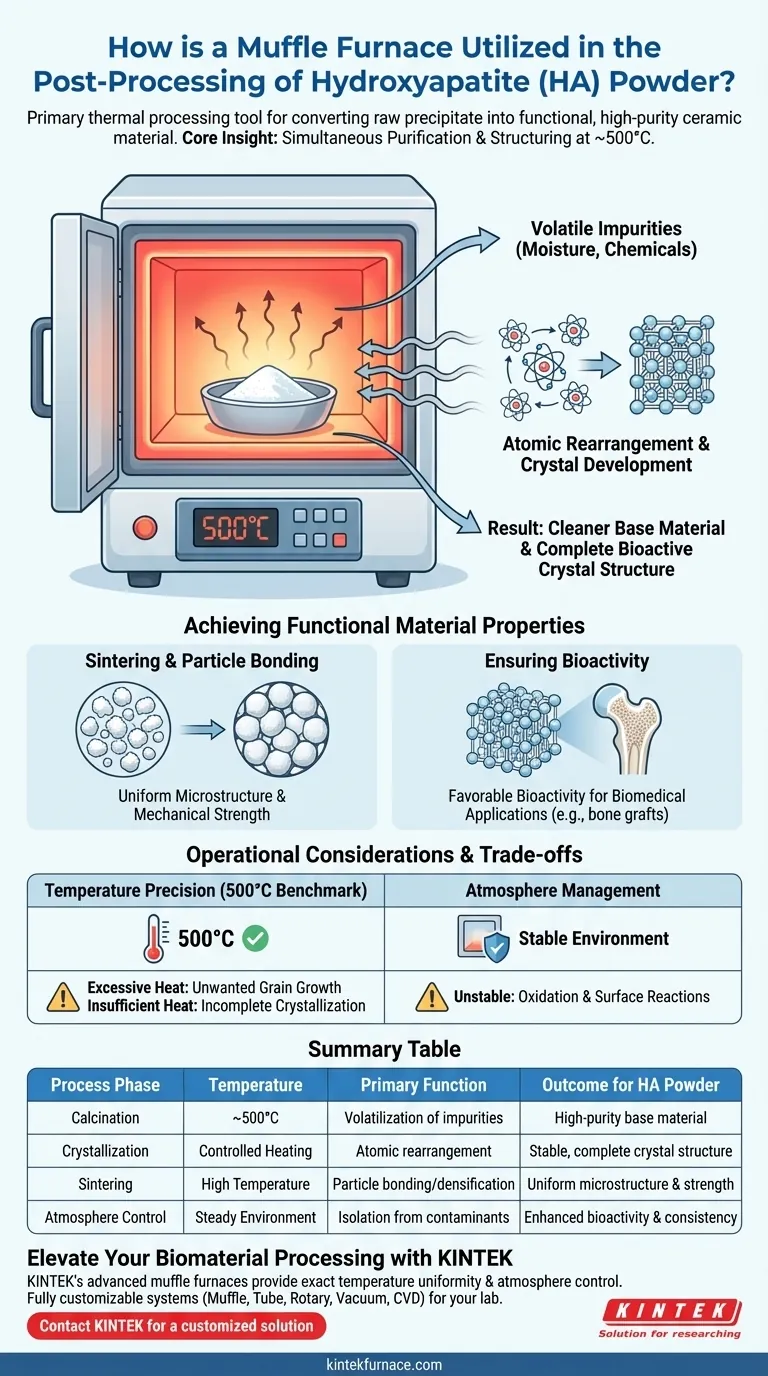

A muffle furnace acts as the primary thermal processing tool for converting precipitated hydroxyapatite (HA) powder into functional ceramic material. It is utilized to execute high-temperature calcination and sintering, typically maintaining a controlled environment of 500°C to transform raw precipitate into stable, high-purity reinforcement particles.

Core Insight: The value of the muffle furnace lies in its ability to simultaneously purify and structure the material. By maintaining a steady 500°C environment, it drives off volatile impurities while forcing the HA powder to develop a complete, bioactive crystal structure.

The Mechanism of Thermal Treatment

To understand the utility of the muffle furnace, one must look beyond simple heating. It is used to drive specific chemical and physical changes in the HA powder.

Eliminating Volatile Impurities

Raw hydroxyapatite precipitate often contains residual moisture or chemical byproducts from the synthesis phase.

The muffle furnace isolates the material in a high-purity environment. By raising the temperature to 500°C, it effectively drives these volatile impurities out of the powder, leaving behind a cleaner base material.

Developing Crystal Structure

The heating process is critical for crystallographic definition.

The thermal energy provided by the furnace allows the atoms within the HA powder to rearrange. This promotes the development of a complete crystal structure, transitioning the material from a potentially amorphous state to a stable crystalline form.

Achieving Functional Material Properties

The post-processing stage determines the final performance of the ceramic in biological applications. The muffle furnace is the engine for this transformation.

Sintering and Particle Bonding

During the sintering phase, the furnace facilitates the densification of the powder.

High heat causes the individual powder particles to bond tightly together. This results in a uniform microstructure, which is essential for consistent mechanical performance in the final product.

Ensuring Bioactivity

The ultimate goal of processing HA is often its use as a reinforcement particle in biomedical applications.

By removing impurities and perfecting the crystal lattice, the muffle furnace ensures the final ceramic particles possess favorable bioactivity. This makes the material suitable for integration into biological systems, such as bone grafts or coatings.

Operational Considerations and Trade-offs

While the muffle furnace is essential, achieving the desired results requires precise control over the operational variables.

Temperature Precision

The 500°C benchmark mentioned is critical.

Deviating from the target temperature can have adverse effects. Excessive heat may lead to unwanted grain growth, degrading mechanical properties, while insufficient heat will result in incomplete crystallization and lower purity.

Atmosphere Management

A key advantage of a muffle furnace is that it separates the heating element from the chamber, preventing combustion contaminants.

However, operators must still monitor the internal atmosphere. For high-purity ceramics, ensuring the chamber environment remains stable is necessary to prevent surface oxidation or unintended chemical reactions during the long dwell times required for sintering.

Optimizing Your Post-Processing Strategy

When utilizing a muffle furnace for hydroxyapatite, your operational parameters should be dictated by your end-goal requirements.

- If your primary focus is Purity and Bioactivity: Strictly maintain the 500°C calcination temperature to ensure complete volatilization of impurities and optimal crystal formation.

- If your primary focus is Mechanical Integrity: Ensure the sintering cycle is sufficient to bond powders tightly, creating a uniform microstructure that resists physical stress.

The muffle furnace is the decisive instrument that transitions hydroxyapatite from a raw chemical precipitate into a functional, high-performance biomaterial.

Summary Table:

| Process Phase | Temperature | Primary Function | Outcome for HA Powder |

|---|---|---|---|

| Calcination | ~500°C | Volatilization of impurities | High-purity base material |

| Crystallization | Controlled Heating | Atomic rearrangement | Stable, complete crystal structure |

| Sintering | High Temperature | Particle bonding/densification | Uniform microstructure & strength |

| Atmosphere Control | Steady Environment | Isolation from contaminants | Enhanced bioactivity & consistency |

Elevate Your Biomaterial Processing with KINTEK

Precision is paramount when transforming hydroxyapatite into high-performance ceramics. KINTEK’s advanced muffle furnaces provide the exact temperature uniformity and atmosphere control required for superior calcination and sintering.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique lab requirements. Ensure the bioactivity and structural integrity of your materials today.

Contact KINTEK for a customized solution

Visual Guide

References

- Omnia Ghabour, Mona Hussein Mohy El Din. Fabrication and evaluation of the mechanical properties of reinforced biodegradable magnesium scaffolds using the space holder method. DOI: 10.21608/adjalexu.2024.290833.1507

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What types of controllers are used in muffle furnaces? Choose the Right One for Precise Thermal Control

- How is the box furnace's door secured and what safety feature does it have? Ensuring Safe Operation with Robust Design

- What are the main applications of a muffle furnace? Unlock Precision Heating for Material Transformations

- What is the significance of using a laboratory high-temperature box furnace for Fe3O4@Al2O3 nanopowders?

- What should be checked after unpacking a muffle furnace? Ensure Safe Setup and Optimal Performance

- How does a high-precision resistance furnace ensure T6 solution treatment? Achieve Peak Alloy Strength with KINTEK

- What role does a laboratory muffle furnace play in the ash analysis of plant samples? Achieve Clean Mineral Isolation

- How do crucible furnaces minimize oxidation losses? Preserve Metal Quality & Maximize Yield