Immediately after unpacking your muffle furnace, you must perform a thorough visual inspection. Check that the furnace body is physically intact with no dents or cracks, and verify that all specified accessories—such as the user manual, power cords, and any included tongs—are present and undamaged. This initial check is your first line of defense against shipping damage and ensures you have everything needed for a proper setup.

Your primary goal extends beyond a simple inventory check. The successful setup of a muffle furnace hinges on three key areas: verifying the unit's physical and electrical integrity, choosing a safe and stable location, and understanding critical operating principles to prevent premature failure.

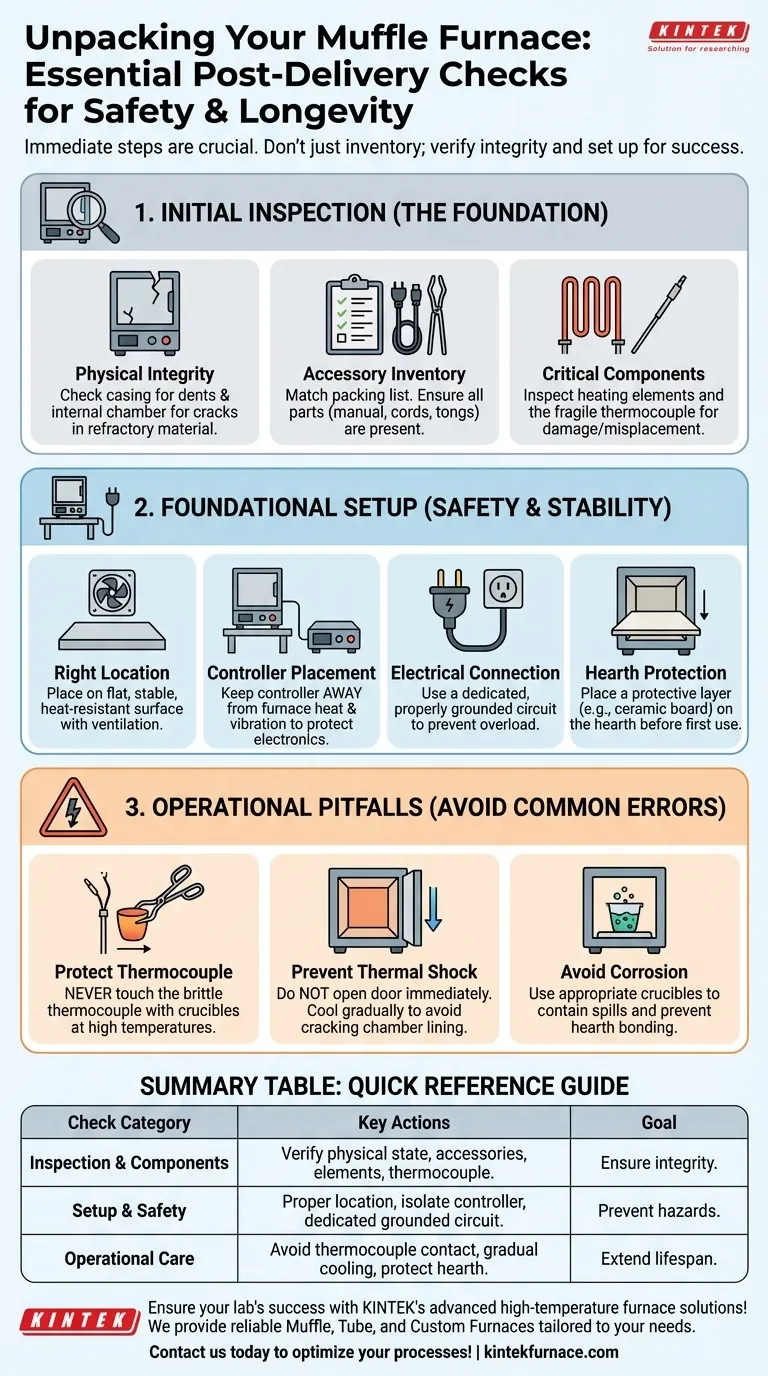

Initial Inspection: The Foundational Checks

Before you plug anything in, a detailed inspection is non-negotiable. This process ensures the unit is safe to operate and performs as expected from day one.

Verifying Physical Integrity

The journey from the factory to your lab can be rough. Look for any signs of damage, paying close attention to the outer casing for dents and the internal chamber for cracks in the refractory material. A compromised chamber can lead to poor performance and safety hazards.

A Complete Accessory Inventory

Cross-reference the contents of the package with the packing list in the user manual. Ensure the correct power cord, controller, crucible tongs, and any other promised accessories are included. Missing components can delay your setup and may indicate an incomplete or previously returned unit.

Inspecting Critical Components

Carefully examine the key internal parts. Ensure the heating elements are securely in place and show no signs of breakage. Most importantly, inspect the thermocouple—the thin rod-like sensor extending into the chamber. It is extremely fragile and critical for accurate temperature control.

Foundational Setup for Safety and Longevity

Where and how you position your furnace is just as important as its internal condition. A poor setup can damage the equipment and create a significant safety risk.

Choosing the Right Location

The furnace must be placed on a flat, stable, and heat-resistant surface or a dedicated shelf. Ensure there is adequate clearance around the unit for ventilation.

Crucially, the controller must be positioned away from the furnace body. Excessive heat and vibration from the furnace can damage the controller's sensitive electronics, leading to inaccurate temperature readings and eventual failure.

Ensuring Proper Electrical Connection

Safety begins with a proper electrical setup. The furnace must be connected to a properly grounded outlet to prevent the risk of electric shock.

It is highly recommended to use a dedicated circuit for the furnace. This prevents overloading your lab's electrical system and ensures a stable power supply, which is essential for consistent heating.

Protecting the Furnace Hearth

Before first use, place a protective layer like a ceramic fiberboard or asbestos board on the floor of the furnace chamber. This protects the hearth from accidental spills, sample splashing, and chemical corrosion, dramatically extending the life of the furnace.

Understanding Critical Operational Pitfalls

Many muffle furnaces are damaged not by defects, but by common and avoidable user errors. Understanding these pitfalls from the start is essential for protecting your investment.

Protecting the Thermocouple at All Costs

The thermocouple is the furnace's nerve center. When placing or removing crucibles, never allow them to touch the thermocouple. It is extremely brittle at high temperatures and can easily break, rendering the furnace inoperable until it is replaced.

Preventing Catastrophic Thermal Shock

The refractory materials inside the furnace are susceptible to cracking from rapid temperature changes. After a heating cycle is complete, do not open the door immediately.

Instead, shut off the power and open the door just a crack. This allows the furnace to cool down gradually, preventing the thermal shock that can fracture the chamber lining. Only open the door fully and remove items with tongs once the temperature has dropped significantly.

Avoiding Hearth Corrosion and Contamination

Always place samples in appropriate high-temperature crucibles or dishes. Poorly contained samples can splash or melt, leading to corrosion and bonding with the furnace hearth. This damage is often irreversible and requires prompt cleaning to prevent further degradation.

Making the Right Choice for Your First Run

Your initial setup and first use should be guided by your primary goals.

- If your primary focus is safety: Double-check that the furnace is properly grounded on a dedicated circuit and is placed on a stable, fire-proof surface.

- If your primary focus is equipment longevity: Prioritize protecting the hearth with a ceramic board and internalizing the rules for gradual cooling to prevent thermal shock.

- If your primary focus is accurate results: Ensure the controller is isolated from the furnace's heat and vibration and that the thermocouple is secure and untouched during operation.

Properly setting up your muffle furnace from the very beginning establishes a foundation for safe, reliable, and long-lasting operation.

Summary Table:

| Check Category | Key Actions |

|---|---|

| Physical Integrity | Inspect for dents, cracks in casing and chamber. |

| Accessory Inventory | Verify user manual, power cords, tongs are present and undamaged. |

| Critical Components | Check heating elements and thermocouple for damage or misplacement. |

| Location Setup | Place on flat, stable, heat-resistant surface with ventilation clearance. |

| Electrical Safety | Connect to grounded outlet and dedicated circuit. |

| Operational Precautions | Avoid thermocouple contact, prevent thermal shock, and protect hearth from spills. |

Ensure your lab's success with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs for enhanced safety, accuracy, and durability. Contact us today to discuss how we can support your setup and optimize your processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency