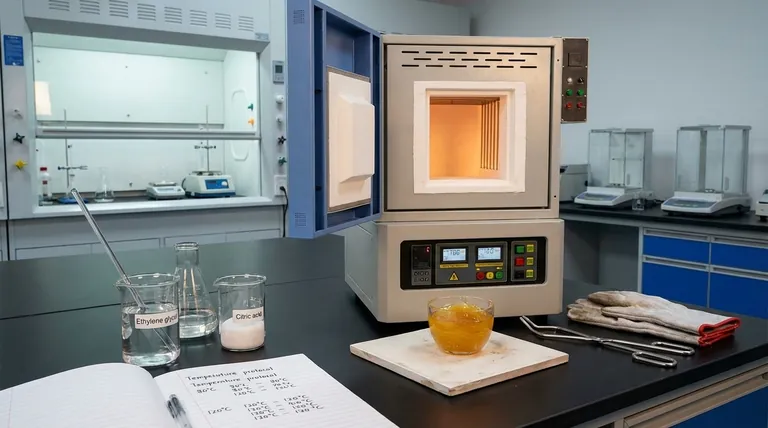

Constant temperature heating equipment is essential for maintaining chemical uniformity. By providing a stable heat source, typically first at 80°C and then at 120°C, this equipment drives the esterification reaction and removes residual solvents without thermal fluctuations. This precise control is critical because it prevents component segregation, ensuring the catalyst precursors develop a stable, homogeneous skeletal structure.

Core Takeaway

In the synthesis of perovskite materials, the quality of the precursor defines the quality of the final product. Constant temperature heating acts as a stabilization mechanism, preventing the physical separation of components (segregation) to ensure a uniform, structurally sound dry gel.

The Mechanism of Gel Formation

Stage 1: Driving Esterification

To initiate the gelation process, the equipment maintains a steady temperature of 80°C.

This specific thermal environment is required to drive the esterification reaction between ethylene glycol and citric acid chelating complexes.

Through dehydration, this reaction transforms the liquid solution into a viscous polymer gel, setting the initial framework for the material.

Stage 2: Solvent Removal

Once the polymer gel is formed, the equipment’s temperature is increased to 120°C.

The primary goal at this stage is the complete removal of residual solvents.

This drying process converts the viscous polymer into a solid, dry gel, locking in the chemical structure created during the first stage.

Why Uniform Heating Determines Quality

Preventing Component Segregation

The most significant risk during gelation is component segregation, where different chemical elements separate rather than remaining mixed.

Segregation is frequently caused by uneven heating or thermal spikes, which drive components apart before they can bond.

Constant temperature equipment eliminates these fluctuations, ensuring that the chemical composition remains homogeneous throughout the material.

Establishing a Stable Skeletal Structure

A high-quality catalyst requires a robust physical framework.

By maintaining precise temperatures during both the reaction and drying phases, the equipment facilitates the formation of a stable skeletal structure.

This structural integrity is vital for the material's performance as a catalyst precursor, as it dictates the porosity and stability of the final perovskite material.

Common Pitfalls to Avoid

The Danger of Thermal Fluctuation

The process relies entirely on the stability of the heat source; even minor deviations can compromise the gel.

If the temperature drops below the target, the esterification reaction may remain incomplete, leading to a weak gel network.

Conversely, unregulated heat spikes can induce rapid solvent evaporation, causing stress fractures or localized segregation within the precursor.

Skipping Protocol Stages

It is a common error to rush the process by accelerating the temperature ramp.

However, the 80°C stage cannot be bypassed or shortened significantly.

Without sufficient time at this lower temperature to form the viscous polymer gel first, the subsequent drying stage at 120°C will likely result in a collapsed or segregated structure rather than a stable dry gel.

Making the Right Choice for Your Goal

To ensure the highest quality perovskite precursors, apply the heating protocol based on your specific quality targets:

- If your primary focus is Chemical Homogeneity: strictly maintain the 80°C phase to allow full esterification, preventing element separation.

- If your primary focus is Structural Stability: ensure the 120°C drying phase is consistent and prolonged enough to remove all solvents without shocking the material.

Mastering the thermal environment is not just about drying; it is about architectural control at the molecular level.

Summary Table:

| Process Stage | Target Temperature | Primary Objective | Impact on Quality |

|---|---|---|---|

| Esterification | 80°C | Drive polymer gel formation | Ensures chemical homogeneity and prevents segregation |

| Drying/Solvent Removal | 120°C | Remove residual solvents | Establishes a stable skeletal structure for the dry gel |

| Thermal Stability | Constant | Eliminate fluctuations | Prevents stress fractures and localized element separation |

Elevate Your Perovskite Synthesis with KINTEK Precision

Achieving molecular-level architectural control requires more than just heat; it requires absolute thermal stability. KINTEK provides industry-leading Muffle, Tube, and Vacuum systems designed specifically for the rigorous demands of catalyst precursor development.

Backed by expert R&D and world-class manufacturing, our lab high-temp furnaces offer the precise temperature uniformity needed to prevent component segregation and ensure a stable skeletal structure for your materials. Whether you need a standard solution or a customized system tailored to your unique gelation protocol, KINTEK is your partner in material excellence.

Ready to optimize your chemical uniformity? Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Shaowei Yao, Tengwei Chen. Tandem catalysis of zeolite and perovskite for light olefins production in dehydrogenation cracking of naphtha. DOI: 10.1039/d5ra02427g

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- For what purpose is a chemically reactive atmosphere used in a furnace? To Transform Material Surfaces

- What is the significance of a controlled atmosphere in a retort furnace? Ensure Purity and Precision in Thermal Processing

- What are the advantages of a hydrogen reducing atmosphere for stainless steel MIM parts? Achieve Superior Integrity

- How is a high-temperature atmosphere furnace utilized during the internal oxidation step of Alumina Dispersion Strengthened Copper (ADSC) production? Unlock Superior Material Strength

- How are the heating elements arranged in the box type annealing atmosphere furnace? For Uniform Heating and Precise Control

- What is a box type annealing atmosphere furnace? Master Controlled Heat Treatment for Superior Materials

- Why is furnace atmosphere important in heat treatment? Master Control for Superior Material Outcomes

- What are the consequences of an improperly controlled furnace atmosphere? Avoid Costly Defects and Safety Hazards