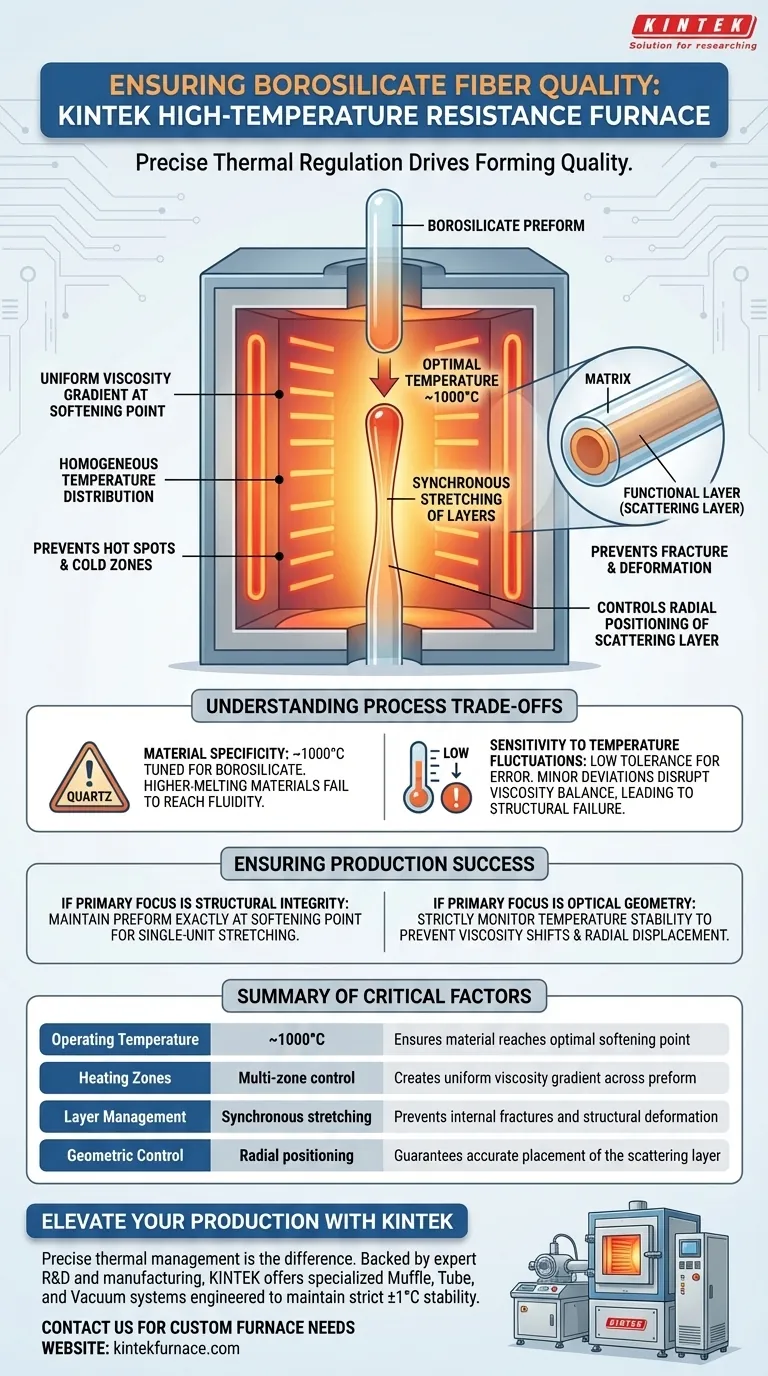

Precise thermal regulation drives the forming quality of borosilicate fibers. An industrial high-temperature resistance furnace ensures integrity by maintaining a specific operating temperature of approximately 1000°C. This controlled environment creates the necessary conditions for complex internal structures to deform uniformly without breaking.

By establishing a uniform viscosity gradient at the preform's softening point, the furnace allows internal functional layers to stretch in perfect sync with the surrounding matrix. This prevents structural deformation and guarantees the accurate radial positioning of the scattering layer.

The Role of Thermal Precision

Operating at the Optimal Temperature

Borosilicate fibers require a distinct thermal approach compared to standard optical materials. The furnace operates at approximately 1000°C, which is significantly lower than the temperatures required for drawing quartz.

Creating a Uniform Viscosity Gradient

The furnace utilizes precise heating zones to manage the state of the preform. This setup ensures a uniform viscosity gradient is established exactly at the material's softening point.

Ensuring Homogeneity

By controlling the temperature distribution, the furnace prevents hot spots or cold zones. This uniformity is essential for the material to flow consistently during the drawing process.

Preserving Structural Integrity

Synchronous Stretching of Layers

High-performance fibers often consist of a matrix and internal functional layers. The furnace’s thermal control allows these distinct layers to stretch synchronously.

Preventing Fracture and Deformation

If the viscosity were mismatched due to uneven heating, the internal layers would crack or distort. The furnace prevents these defects, ensuring the fiber is drawn without fracture or deformation.

Controlling Radial Positioning

The ultimate goal of this thermal precision is geometric accuracy. It ensures the scattering layer is maintained at its precise radial position, which is critical for the fiber's optical function.

Understanding the Process Trade-offs

Material Specificity vs. Versatility

The temperature profile (~1000°C) is specifically tuned for borosilicate. Attempting to process higher-melting-point materials (like quartz) in this specific configuration would fail, as they would not reach the necessary fluidity.

Sensitivity to Temperature Fluctuations

Because the process relies on the synchronous stretching of different layers, the tolerance for temperature error is low. Even minor deviations can disrupt the viscosity balance, leading to immediate structural failure inside the fiber.

Ensuring Production Success

To maximize the quality of borosilicate fiber drawing, consider the following process goals:

- If your primary focus is Structural Integrity: Ensure the heating zones maintain the preform exactly at the softening point to allow the matrix and functional layers to stretch as a single unit.

- If your primary focus is Optical Geometry: Strictly monitor the temperature stability to prevent viscosity shifts that would displace the radial position of the scattering layer.

Precise thermal management is the defining factor in transitioning a complex preform into a high-performance optical fiber.

Summary Table:

| Feature | Requirement | Impact on Quality |

|---|---|---|

| Operating Temperature | Approximately 1000°C | Ensures material reaches optimal softening point |

| Heating Zones | Multi-zone control | Creates uniform viscosity gradient across preform |

| Layer Management | Synchronous stretching | Prevents internal fractures and structural deformation |

| Geometric Control | Radial positioning | Guarantees accurate placement of the scattering layer |

Elevate Your Optical Fiber Production with KINTEK

Precise thermal management is the difference between structural failure and a high-performance optical fiber. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, and Vacuum systems engineered to maintain the strict ±1°C stability required for borosilicate drawing.

Whether you need custom heating zones to ensure synchronous layer stretching or a tailored furnace for unique functional materials, our systems provide the reliability your lab demands. Contact us today to discuss your custom furnace needs and see how our expertise can optimize your manufacturing process.

Visual Guide

References

- Jan Schröder, Lothar Wondraczek. Functional Optical Fibers with Tailored Side Emission from Modified Rod‐in‐Tube Preforms. DOI: 10.1002/adpr.202500018

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the function of a top-blown oxygen-nitrogen system? Precision Control for High-Yield Smelting

- Why is it necessary to use an annealing furnace at 350°C for three hours? Ensuring Glass Stability and Clarity

- What is the purpose of using an industrial oven for the pretreatment of reinforcement powders? | Enhance Composite Bond

- Why is it necessary to preheat the mold for Mg-8Li-3Al-0.3Si alloy? Unlock Peak Casting Integrity

- What role does phosphoric acid (H3PO4) play during the chemical activation stage of sawdust? Boost Porosity & Efficiency

- How does the pre-oxidation process affect high-temperature alloys? Enhancing Surface Integrity for Steam Cracking

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- What role does thermal processing with precise temperature control and tensile stress play in PVDF fiber stabilization?