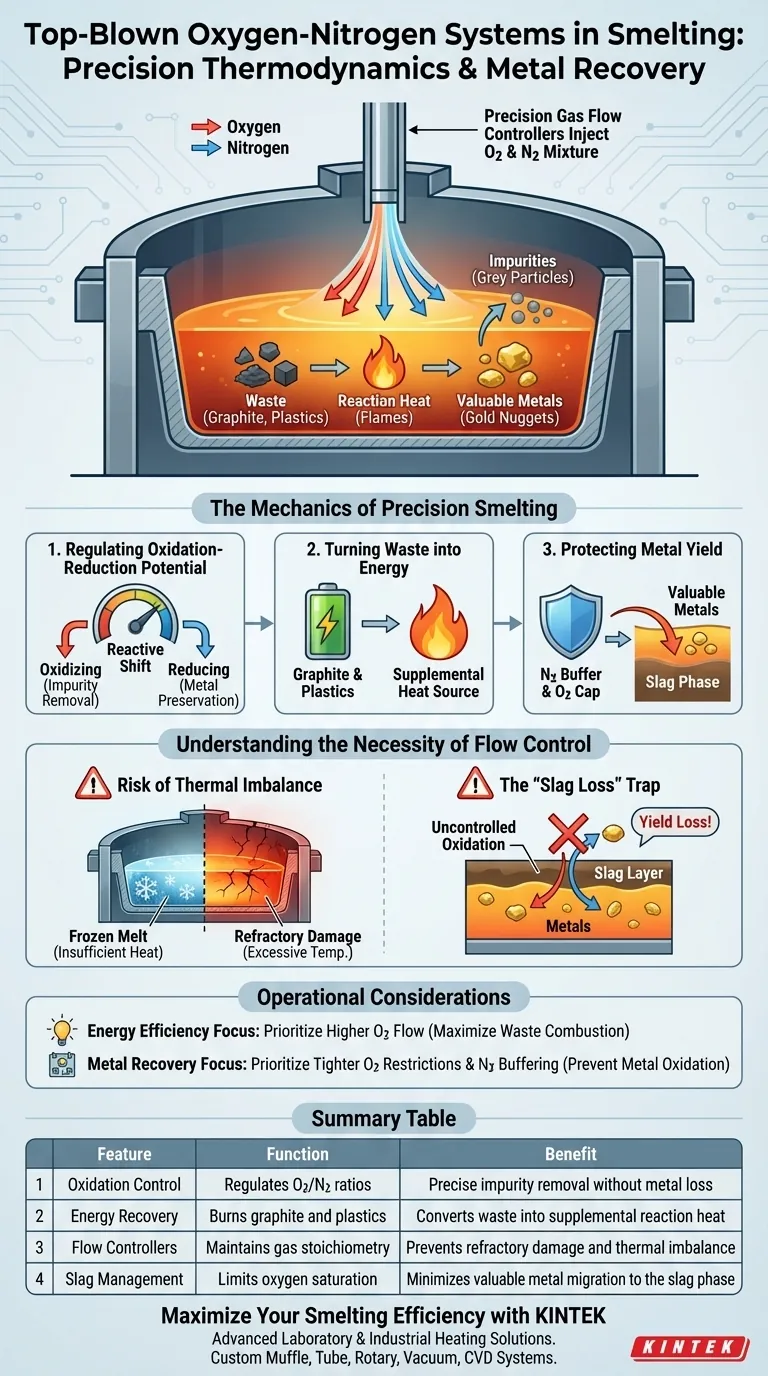

A top-blown oxygen-nitrogen system serves as a precision control mechanism for smelting thermodynamics. By utilizing gas flow controllers to inject a specific mixture of oxygen and nitrogen onto the melt surface, this system manages the oxidation-reduction potential to balance impurity removal with metal recovery. Its primary function is to optimize the chemical environment, allowing for the selective burning of waste materials while protecting valuable metals.

By modulating the gas mixture, this system transforms waste components into a supplemental energy source. It allows operators to burn off graphite and plastics for heat while strictly preventing the over-oxidation that causes valuable metals to be lost to the slag.

The Mechanics of Precision Smelting

Regulating Oxidation-Reduction Potential

The core capability of this system is the precise control over the oxidation-reduction potential within the furnace. By adjusting the ratio of oxygen to nitrogen via the flow controllers, operators can dictate the chemical reactivity of the melt surface.

This control allows the process to shift between oxidizing conditions (to remove impurities) and reducing conditions (to preserve metal) as needed.

Turning Waste into Energy

In processes involving battery materials, the feed often contains excess graphite powder and plastic separators. The top-blown oxygen system targets these carbon-based materials.

By injecting oxygen, the system burns these components, effectively treating them as fuel. This generates reaction heat, which serves as supplemental energy for the smelting process, reducing the need for external power sources.

Protecting Metal Yield

While oxidation is necessary to burn waste and generate heat, uncontrolled oxidation is detrimental to yield. If too much oxygen is introduced, valuable reduced metals will oxidize and be lost to the slag phase.

The gas flow controllers mitigate this risk by capping oxygen levels or introducing nitrogen to dilute the oxidative effect. This ensures that while waste is burned, the valuable metallic components remain in the metal phase.

Understanding the Necessity of Flow Control

The Risk of Thermal Imbalance

This process relies heavily on the heat generated from burning graphite and plastics. Without the precision of gas flow controllers, the reaction rate could fluctuate wildly.

Inaccurate flow rates could lead to insufficient heat generation (freezing the melt) or excessive temperatures that damage the refractory lining.

The "Slag Loss" Trap

The most critical trade-off in this system is the balance between cleaning the melt and losing metal.

If the system fails to restrict oxygen flow once the impurities are burned, the process will immediately begin attacking the valuable metals. The flow controllers act as the critical safeguard against this yield loss.

Operational Considerations for Your Process

The effectiveness of a top-blown oxygen-nitrogen system depends on how you tune the controllers relative to your feedstock composition.

- If your primary focus is Energy Efficiency: prioritize a higher oxygen flow rate initially to maximize the combustion of graphite and plastic, utilizing the full potential of the reaction heat.

- If your primary focus is Metal Recovery: prioritize tighter restrictions on oxygen flow and utilize nitrogen buffering to ensure the oxidation potential never rises high enough to drive metals into the slag.

This system effectively turns a waste disposal challenge into a thermal asset, provided the gas ratios remain strictly controlled.

Summary Table:

| Feature | Function | Benefit |

|---|---|---|

| Oxidation Control | Regulates O2/N2 ratios | Precise impurity removal without metal loss |

| Energy Recovery | Burns graphite and plastics | Converts waste into supplemental reaction heat |

| Flow Controllers | Maintains gas stoichiometry | Prevents refractory damage and thermal imbalance |

| Slag Management | Limits oxygen saturation | Minimizes valuable metal migration to the slag phase |

Maximize Your Smelting Efficiency with KINTEK

Take control of your thermodynamics with KINTEK’s advanced laboratory and industrial heating solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temperature furnaces—all fully customizable to meet your specific smelting and material processing needs.

Whether you are refining battery materials or optimizing metal recovery, our systems provide the precision required to turn waste into energy while protecting your yield.

Ready to elevate your thermal processing? Contact our experts today to discuss your custom solution.

Visual Guide

References

- Chen Wang, Hongbin Ling. Extraction of Valuable Metals from Spent Li-Ion Batteries Combining Reduction Smelting and Chlorination. DOI: 10.3390/met15070732

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does temperature control affect nanoporous copper dealloying? Master Pore Uniformity and Size

- Why is the vacuum drying process essential for the synthesis of phthalonitrile-modified titanium dioxide? Expert Guide

- Why is it necessary to preheat the mold for Mg-8Li-3Al-0.3Si alloy? Unlock Peak Casting Integrity

- How is a laboratory oven utilized during the impregnation stage of APC preparation? Optimize Biochar Activation

- What is the function of controlled hot air flow treatment in ZnO drying? Master Surface Flatness and Stress Reduction

- How does an annealing furnace improve Indium Selenide thin films? Optimize Your Photoanode Energy Efficiency Today

- What are the primary functions of a high-precision dilatometer in hot ductility? Optimize Steel Casting Precision

- What is the technical necessity of heating and stirring for K-Na alloy anodes? Ensure Peak Battery Performance