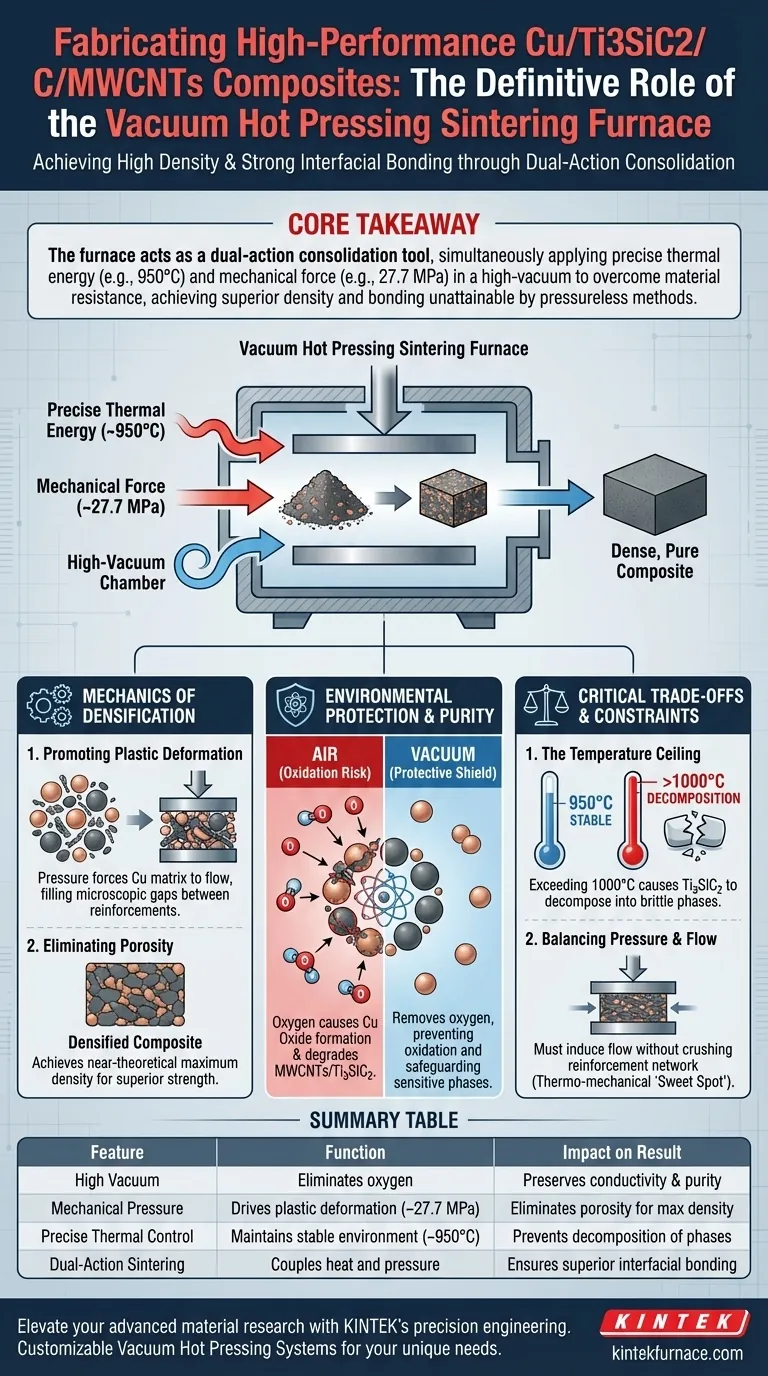

A vacuum hot pressing sintering furnace acts as the definitive processing environment for fabricating high-performance Cu/Ti3SiC2/C/MWCNTs composites. It simultaneously applies precise thermal energy (typically 950°C) and mechanical force (around 27.7 MPa) within a high-vacuum chamber. This specific combination drives the plastic deformation of the copper matrix to eliminate porosity while shielding sensitive carbon nanotubes and ceramic phases from destructive oxidation.

Core Takeaway The furnace functions not merely as a heater, but as a dual-action consolidation tool. By coupling mechanical pressure with thermal energy in a vacuum, it overcomes the natural resistance of the material to sinter, achieving high density and strong interfacial bonding that pressureless methods cannot replicate.

The Mechanics of Densification

Promoting Plastic Deformation

The primary challenge in sintering this composite is eliminating internal voids. The furnace applies significant mechanical pressure (e.g., 27.7 MPa) which forces the copper matrix particles to undergo plastic deformation. This flow allows the metal to fill the microscopic gaps between the harder Ti3SiC2 and MWCNT reinforcements.

Eliminating Porosity

By mechanically compressing the powder mixture while it is softened by heat, the furnace physically closes pores. This process is far more effective than relying on thermal diffusion alone. The result is a composite with a density that approaches the theoretical maximum, ensuring superior mechanical strength and conductivity.

Environmental Protection and Purity

Preventing Matrix Oxidation

Copper is highly susceptible to oxidation at sintering temperatures. The furnace’s high-vacuum environment removes atmospheric oxygen. This prevents the formation of copper oxide inclusions, which would otherwise weaken the material and disrupt electrical conductivity.

Safeguarding Reinforcement Phases

Both Carbon Nanotubes (MWCNTs) and MAX phase ceramics (Ti3SiC2) are sensitive to high-temperature degradation in air. The vacuum creates a protective shield, preserving the structural integrity of the nanotubes and the stoichiometry of the ceramic phase. This ensures strong interfacial bonding between the matrix and the reinforcement, preventing brittle fractures.

Critical Trade-offs and Constraints

The Temperature Ceiling

While heat is necessary for sintering, precise control is paramount. The furnace must maintain stability around 950°C. If temperatures exceed 1000°C, the Ti3SiC2 phase can thermally decompose into brittle TiC phases and Cu-Si compounds, degrading the composite's ductility.

Balancing Pressure and Flow

The mechanical pressure must be sufficient to induce flow but controlled to avoid damaging the reinforcement structures. The vacuum hot pressing method relies on finding the thermo-mechanical "sweet spot" where the matrix flows without crushing the reinforcement network or triggering unwanted chemical reactions.

Making the Right Choice for Your Goal

- If your primary focus is Maximum Density: Ensure the furnace can sustain mechanical pressure (approx. 27-30 MPa) throughout the holding time to force material into all inter-particle voids.

- If your primary focus is Material Purity: Prioritize a furnace with high-vacuum capabilities to eliminate oxygen, ensuring the MWCNTs and Ti3SiC2 remain chemically intact.

- If your primary focus is Phase Stability: strictly limit the processing temperature to 950°C to prevent the irreversible decomposition of the Ti3SiC2 reinforcement.

Successful fabrication relies on the strict synchronization of temperature, pressure, and vacuum to densify the material without degrading its complex internal structure.

Summary Table:

| Feature | Function in Composite Fabrication | Impact on Result |

|---|---|---|

| High Vacuum | Eliminates oxygen to prevent copper oxidation | Preserves electrical conductivity and purity |

| Mechanical Pressure | Drives plastic deformation (approx. 27.7 MPa) | Eliminates porosity for maximum density |

| Precise Thermal Control | Maintains stable environment (approx. 950°C) | Prevents decomposition of Ti3SiC2 and MWCNTs |

| Dual-Action Sintering | Couples heat and pressure simultaneously | Ensures superior interfacial bonding vs. pressureless methods |

Elevate your advanced material research with KINTEK’s precision engineering. Backed by expert R&D and manufacturing, KINTEK offers specialized Vacuum Hot Pressing systems and other lab high-temp furnaces, including Muffle, Tube, Rotary, and CVD systems, all fully customizable for your unique fabrication needs. Whether you are developing Cu-based composites or advanced ceramics, our technology ensures the density and purity your project demands. Contact KINTEK today to discuss your custom solution!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the advantages of using Spark Plasma Sintering (SPS) for Mo-Cr-Y composites? High-Performance Fabrication

- What is the core function of a vacuum hot pressing furnace? Expert Guide to TiAl/Ti6Al4V Composite Success

- How does a vacuum hot press sintering furnace mitigate copper sintering swelling? Solve Fe-Cu Expansion Issues

- How does the application of mechanical pressure contribute to the vacuum hot pressing formation of TiAl/Ti6Al4V? Expert Analysis

- How does the vacuum environment in a vacuum hot press sintering furnace protect chromium-containing ceramics? Find out.

- What are the typical operational steps when using a vacuum press? Master Flawless Bonding and Forming

- What is the primary function of a vacuum hot pressing furnace? Expert Guide to AlMgTi Composite Preparation

- Why is a medium frequency induction heating system utilized in the manufacture of diamond drills via vacuum hot pressing? For Superior Speed and Durability