Precise thermal regulation is the critical mechanism behind high-quality phenyl-modified carbon nitride (PhCN) synthesis. A tube furnace ensures modification quality by applying a strictly controlled, linear heating program—such as ramping to 400 °C over one hour—to precursors housed within a quartz tube. This controlled thermal energy is what drives the chemical integration of phenyl groups into the material's skeleton.

Core Insight The tube furnace’s ability to maintain linear temperature control is the primary driver for successful modification. This precision allows phenyl groups to integrate effectively into the triazine or heptazine skeleton, directly resulting in an expanded pi-conjugated system and an optimized bandgap structure.

The Mechanics of Structural Modification

To understand why the tube furnace is essential, you must look at how thermal energy dictates the atomic structure of the final material.

Ensuring Successful Phenyl Integration

The synthesis of PhCN is not merely about reaching a specific temperature; it is about the rate of heating.

The tube furnace utilizes a specific heating program (e.g., a steady increase over a set duration). This linear temperature control provides the exact activation energy required for phenyl groups to bond with the carbon nitride precursors.

Without this linearity, the integration process could be uneven, leading to inconsistent material properties.

Expanding the Pi-Conjugated System

The ultimate goal of this thermal treatment is structural evolution.

By forcing the integration of phenyl groups into the triazine or heptazine skeleton, the furnace facilitates the expansion of the material's pi-conjugated system.

This structural expansion is the physical basis for the material's improved electronic properties.

Optimizing Bandgap Structure

The structural changes driven by the furnace have a direct impact on performance.

The controlled introduction of phenyl groups modifies the electronic band structure of the carbon nitride. Consequently, the tube furnace process is directly responsible for optimizing the bandgap structure, making the material more effective for its intended application.

Environmental Control and Material Purity

While thermal linearity is the primary driver for PhCN, the physical design of the tube furnace plays a supportive role in maintaining quality.

Isolation via Quartz Tube

The processing takes place within a quartz tube.

This physical barrier allows for the processing of precursors in a contained environment. While the primary mechanism is heating, the containment helps ensure the reaction proceeds without physical disruption.

Minimizing Contamination Risks

Although specific to broader tube furnace applications, the enclosed nature of the system is critical for purity.

By isolating the sample, the furnace protects the material from reacting with uncontrolled surrounding gases. This reduction in oxidation or corrosion risks is vital for maintaining the chemical integrity of the modified carbon nitride.

Understanding the Trade-offs

While tube furnaces offer precision, there are operational constraints you must consider to ensure consistent quality.

Dependency on Programming Accuracy

The quality of the PhCN is entirely dependent on the linearity of the heating program.

If the temperature ramp deviates from the linear profile (e.g., heating too fast or fluctuating), the phenyl groups may not integrate correctly into the skeleton. This can lead to a failure in expanding the pi-conjugated system.

Throughput Limitations

Tube furnaces are typically batch-processing tools.

Because the process relies on a specific time-domain program (e.g., 1 hour to reach 400 °C) inside a quartz tube, the volume of material produced per run is limited by the tube's dimensions and the heating zone's uniformity.

Making the Right Choice for Your Goal

When setting up your synthesis protocol, tailor your approach to your specific outcome.

- If your primary focus is structural integrity: Prioritize the linearity of your heating ramp to ensure the phenyl groups bond uniformly with the heptazine skeleton.

- If your primary focus is electronic performance: Calibrate your final temperature target strictly, as this dictates the extent of the bandgap optimization and pi-system expansion.

Ultimately, the tube furnace acts as a precision instrument that translates thermal energy into specific atomic arrangements, defining the final quality of your material.

Summary Table:

| Key Feature | Role in PhCN Synthesis | Impact on Material Quality |

|---|---|---|

| Linear Heating Program | Drives uniform chemical integration of phenyl groups | Prevents structural defects and ensures consistency |

| Quartz Tube Isolation | Contained reaction environment | Minimizes contamination and protects chemical integrity |

| Thermal Precision | Facilitates pi-conjugated system expansion | Optimizes bandgap structure and electronic performance |

| Controlled Activation | Provides exact energy for skeleton bonding | Ensures successful phenyl-to-heptazine integration |

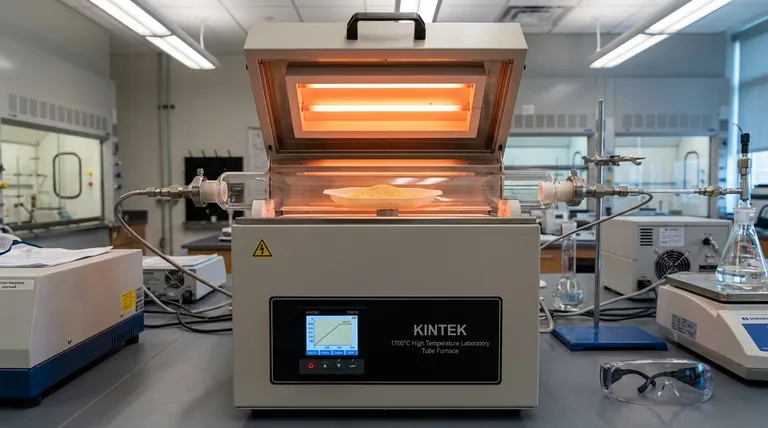

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect pi-conjugated system in PhCN requires more than just heat—it requires the absolute thermal linearity and environmental control that only a specialized furnace can provide. KINTEK delivers industry-leading Tube, Muffle, Vacuum, and CVD systems, all engineered to provide the exact ramping protocols necessary for high-performance chemical modification.

Our expert R&D team specializes in customizable high-temperature lab furnaces tailored to your unique research or production needs. Don't let fluctuating temperatures compromise your material's bandgap structure.

Contact KINTEK today to discuss your custom furnace solution and ensure your synthesis meets the highest standards of purity and performance.

Visual Guide

References

- Riccardo Dettori, Pier Carlo Ricci. Sustainable Photocatalysis with Phenyl-Modified g-C3N4/TiO2 Polymer Hybrids: A Combined Computational and Experimental Investigation. DOI: 10.3390/polym17101331

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of introducing high-purity argon into the tube furnace? Expert Pyrolysis Solutions

- What is the function of vacuum-sealed tubes and controlled heating? Master Ruthenium Precursor Embedding

- What is a vertical furnace? A Guide to High-Purity, Uniform Thermal Processing

- What role does a tube furnace play in NaRu2O4 synthesis? Master Solid-State Reaction & Phase Purity

- What is the primary function of a high-temperature tube furnace in Se@void@BLNC preparation? Master Dual Synthesis

- What is the primary function of a tube furnace for REBCO tapes? Find Critical 175°C Thresholds

- How do tube furnaces and isolation valves simulate TCOP experiments? Expert Setup for Thermochemical Oxygen Pumps

- How is an electric tubular furnace defined and what are its main functions? Unlock Precision Heating for Your Lab